An automobile waxing device capable of automatically supplying materials

A technology for feeding materials and automobiles, which is applied in vehicle maintenance, transportation and packaging, vehicle maintenance/repair, etc. It can solve the problems of low waxing material efficiency, affecting work efficiency, manual waxing material, etc., to achieve high work efficiency and operation. The process is labor-saving and the effect of preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

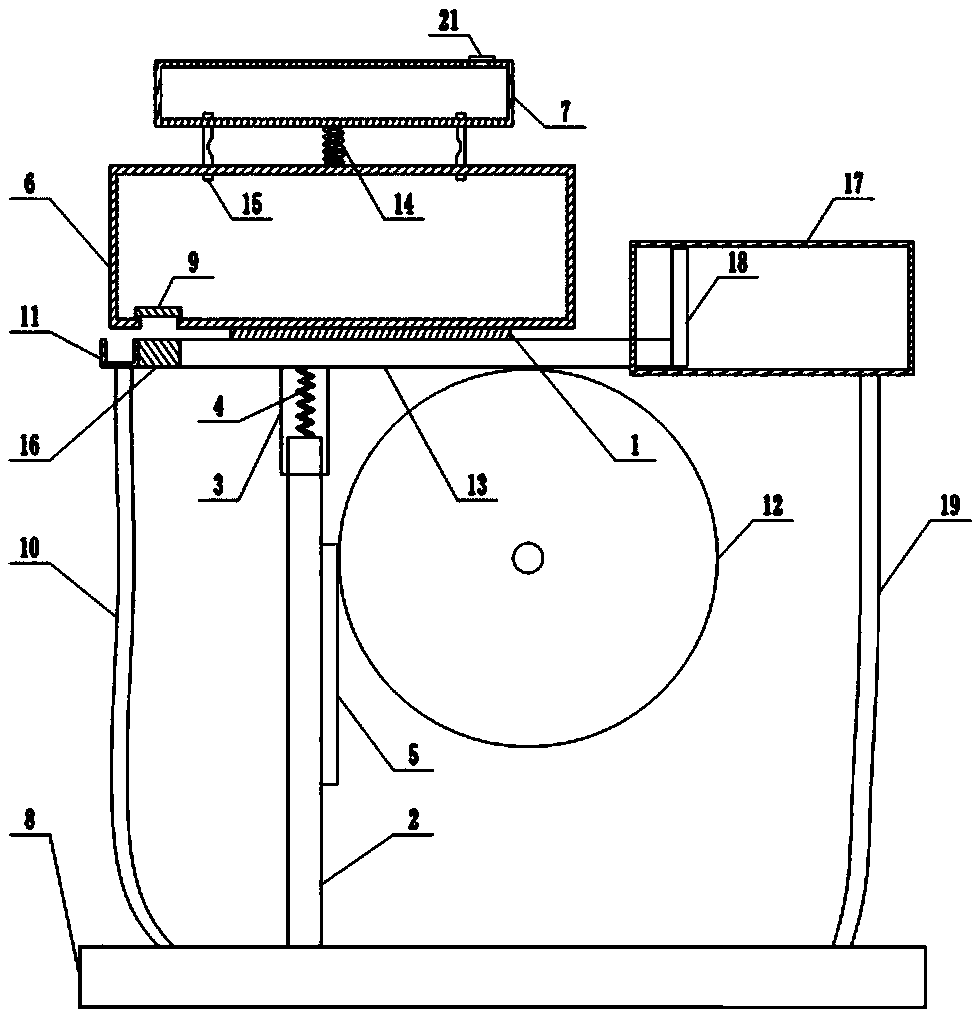

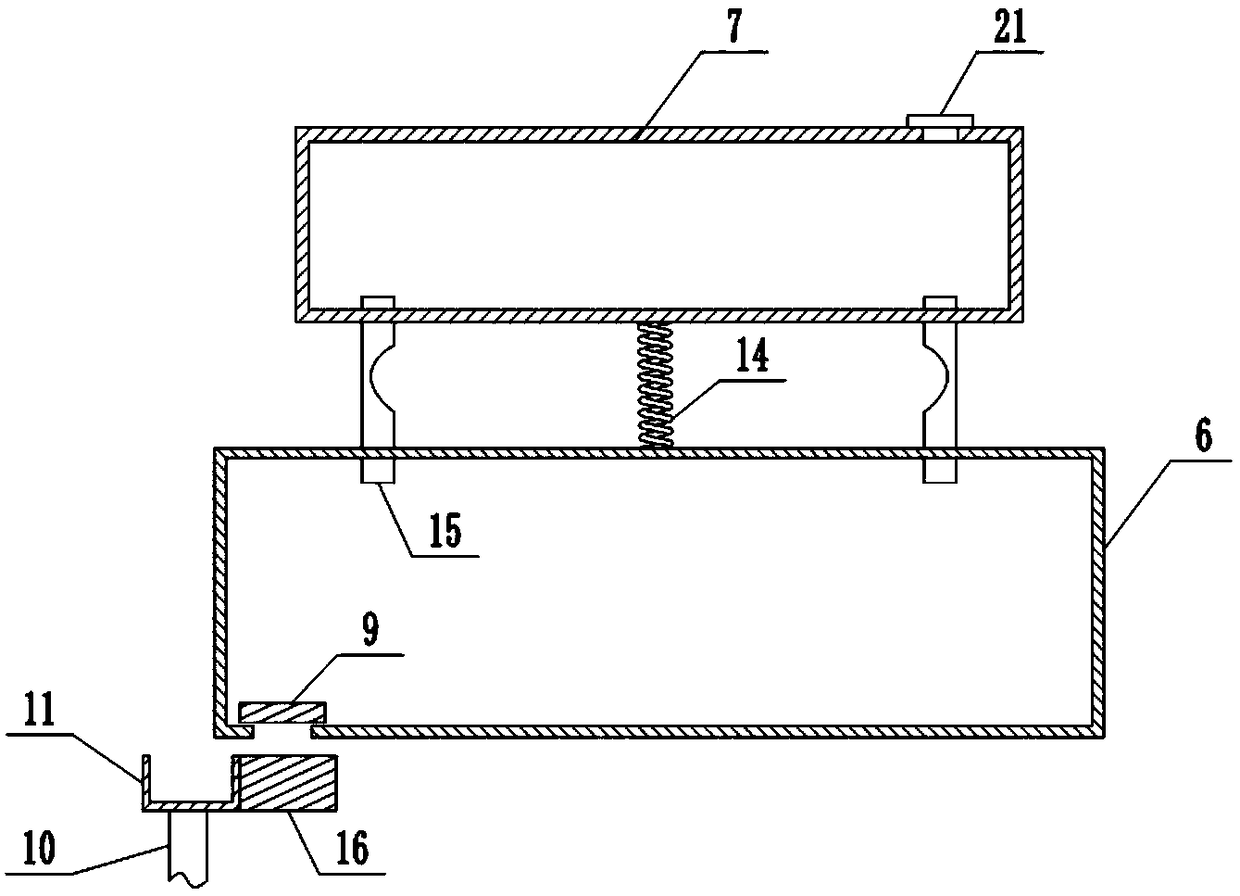

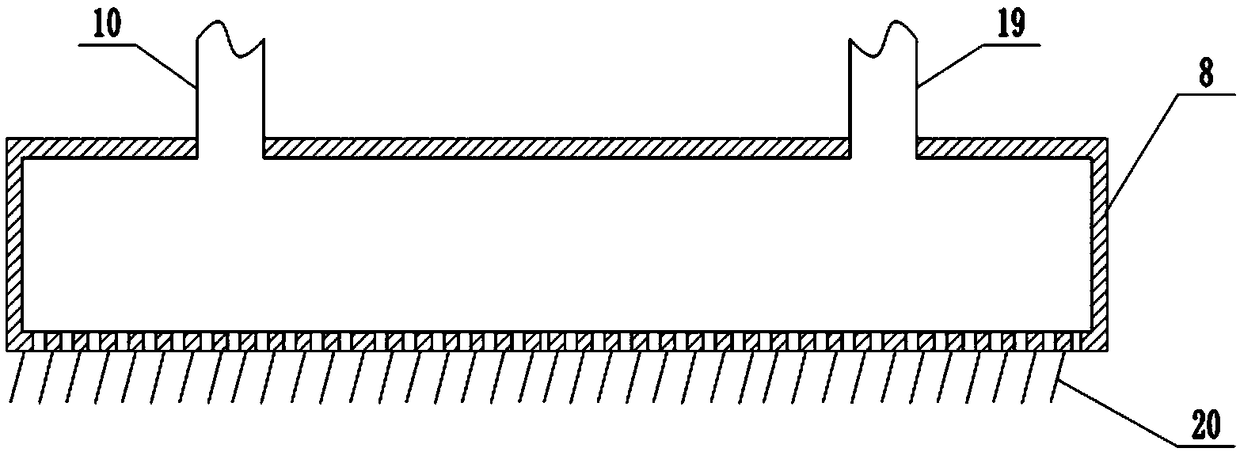

[0021] The specific implementation of the present invention is as follows: the operator puts the device on a clean car surface or other objects, pushes the brush plate 8 downward, and the brush plate 8 is subjected to a reaction force, thereby driving the ejector rod 2 to move upward, and compressing the first spring 4. During this process, the first rack 5 fixedly connected to the ejector rod 2 drives the gear 12 to rotate, and the gear 12 drives the second rack 13 to move away from the feeding port; the second magnet on the second rack 13 16 Adsorb the first magnet 9 to slide on the bottom plate of the material storage box 6. After the first magnet 9 slides, the feeding port is no longer closed. The wax material flows into the receiving tank 11 from the feeding port, and then flows into the brush plate 8 through the first hose 10 Inside, it finally flows out from the through hole, so that the wax is evenly distributed on the bristles 20; at the same time, the second rack 13 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com