Micro-interface enhancement reactor reaction rate structure-activity regulation and control model modeling method

A technology of reaction rate and model modeling, applied in the direction of adaptive control, instrument, general control system, etc., can solve the problems of high energy consumption and manufacturing cost of microbubble equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0301] This embodiment specifically illustrates the technical solution of the modeling method of the present invention.

[0302] The method of the present invention specifically includes the following steps:

[0303] Obtain the process conditions of the micro-interface enhanced reactor reaction system, including catalyst, temperature, pressure, and material ratio; calculate the gas-liquid reaction rate;

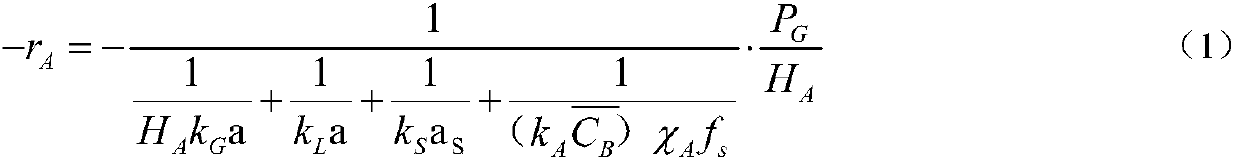

[0304] Based on Levenspiel's theory, the reaction rate of a multiphase system is expressed by the following formula:

[0305]

[0306] In the above formula, r A Is the reaction rate of reactant A, mol(A) / m -3 (reactor)·s; H A Is the Henry's constant of reactant A, Pa·m 3 / mol; k G , K L , K S They are the mass transfer coefficients of gas side, liquid side and liquid-solid, m / s. a, a S Respectively the area of the gas-liquid boundary, the area of the liquid-solid boundary, m 2 / m 3 ;K A Is based on the reaction rate r A The first order intrinsic reaction rate constant, m 3 (A) / m ...

Embodiment 2

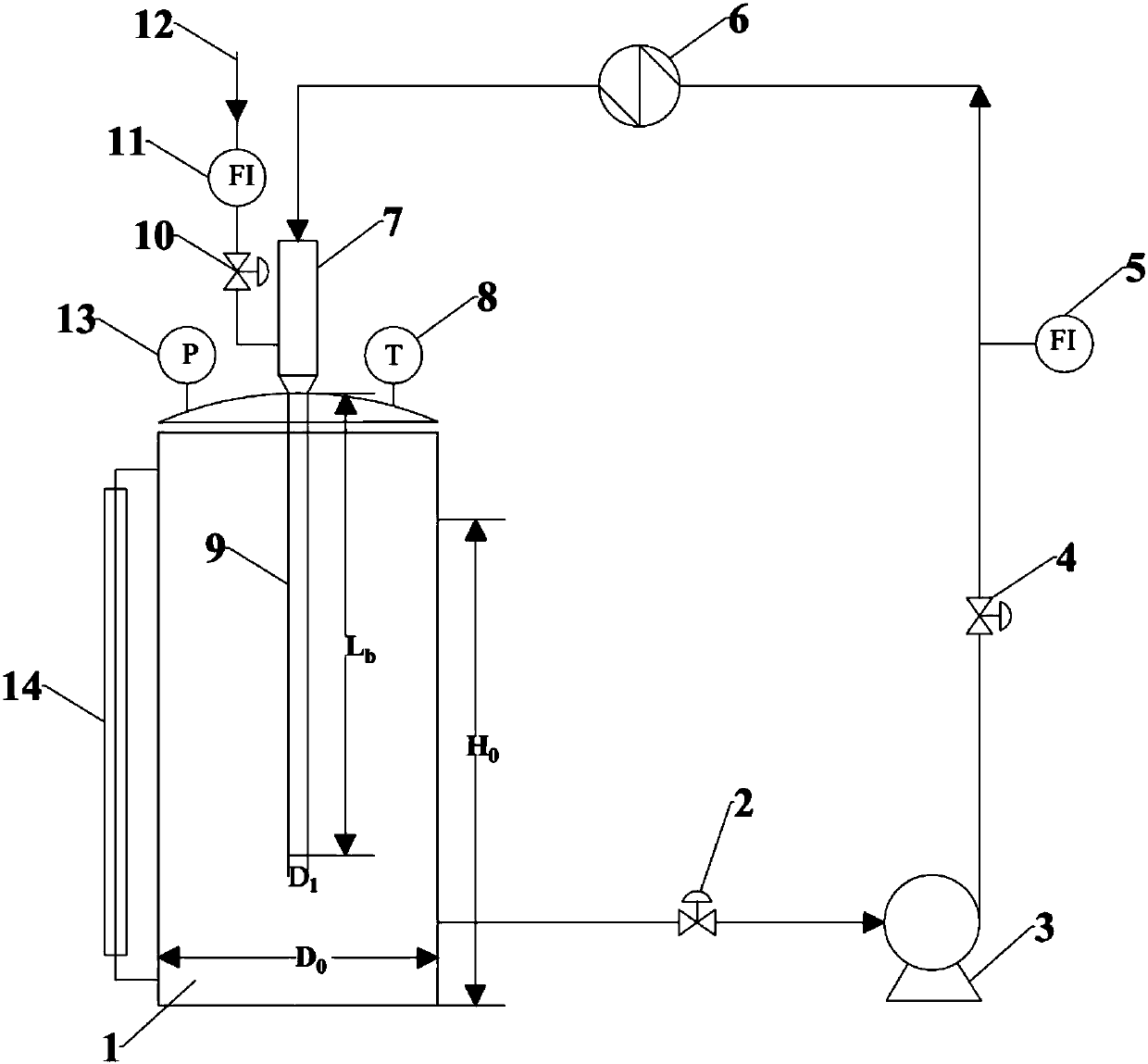

[0546] This embodiment is based on figure 1 The shown reactor is taken as an example to illustrate the application of the model constructed by the modeling method described in Example 1 in a carbon dioxide and water system reactor. figure 1 The structure of the reactor can be the structure of an existing reactor, and only the method of the present invention is used for parameter design, and the structure of the reactor is not repeated in the present invention.

[0547] The structure-activity control model of the reaction rate constructed according to Example 1 is as follows:

[0548]

[0549]

[0550]

[0551]

[0552]

[0553]

[0554] d min = 11.4(μ L / ρ L ) 0.75 ε -0.25 (72)

[0555] d max =0.75(σ L / ρ L ) 0.6 ε -0.4 (75)

[0556]

[0557]

[0558]

[0559]

[0560]

[0561]

[0562]

[0563]

[0564]

[0565]

[0566]

[0567] Where k G Is the gas mass transfer coefficient, mol / (Pa·m 3 ·S); k L Is the gas mass transfer coefficient, m / s; k A Is based on the reaction rate r A ...

Embodiment 3

[0573] This embodiment is based on figure 1 The reactor shown is an example to illustrate the application of the model constructed by the modeling method described in Example 1 in the air-water system reactor, and the reaction rate r in the reaction system of the existing device A Compared with the superiority.

[0574] Table 3 and Table 4 are the comparison of various parameters of the same system with different particle sizes:

[0575] Table 3 Parameters calculated by the model formula under different particle sizes

[0576]

[0577] Table 4 Three resistances (gas film, liquid film, intrinsic) calculated by the model formula under different particle sizes

[0578]

[0579] As shown in Table 3 and Table 4, under the same conditions, compared to the bubble produced by the traditional reactor with a minimum diameter of 1mm, the bubble produced by MIR is only 0.1mm in diameter, which is 1 / 10 of the original. It is about 4 times larger than the former, and the reaction resistance gradu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com