Method for preparing optical super-structure surface based on nanoimprinting

A metasurface, nano-imprinting technology, applied in nano-optics, originals for opto-mechanical processing, optics, etc., can solve the problems of long preparation time and high cost, optimize production process, save production cost, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] This embodiment provides a method for preparing an optical metasurface optical device based on nanoimprinting, the specific method is:

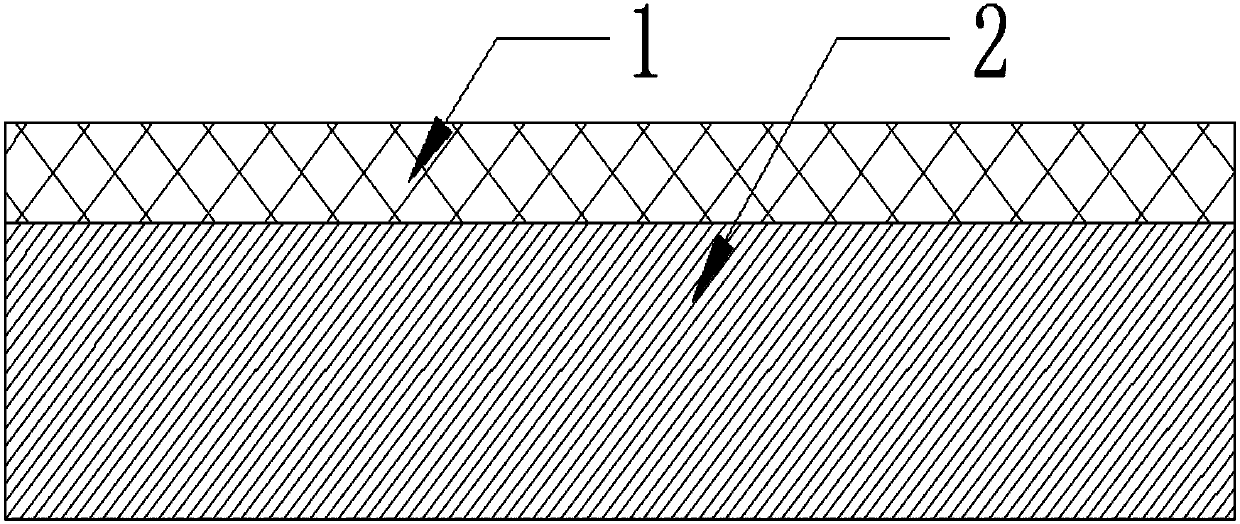

[0081] a. Spin-coat a layer of electron beam lithography positive resist 1 with a thickness of about 150 nm on the silicon wafer 2 (the schematic diagram of the product is as follows Figure 1.1 shown);

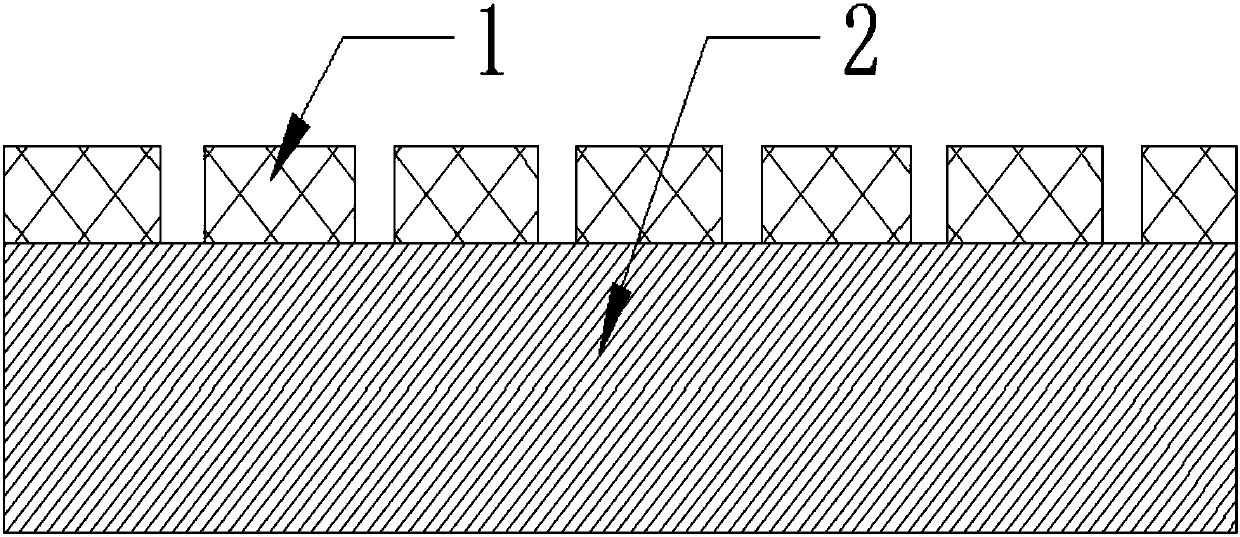

[0082] b. Use electron beam lithography to write the designed metasurface functional element pattern, and develop it with a developer (the schematic diagram of the product is as follows Figure 1.2 shown);

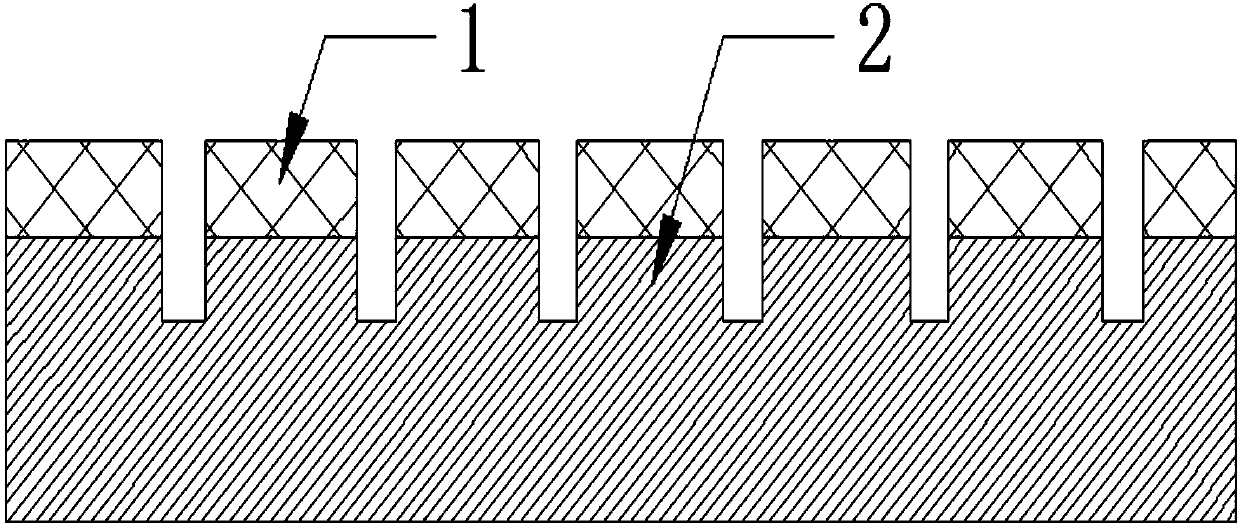

[0083] c. Use the electron beam lithography positive resist 1 as a mask to perform ICP etching on the silicon wafer 2, and the etching depth is about 200nm (the schematic diagram of the product is as follows Figure 1.3 shown);

[0084] d. Remove the electron beam photoresist positive resist 1 with the corresponding solvent (the schematic diagram of the product is as follows Figure 1.4 shown);

[0085] e. Evaporate a layer of...

Embodiment 2

[0094] This embodiment provides a method for preparing an optical metasurface optical device based on nanoimprinting, the specific method is:

[0095] a. With reference to the four steps of a, b, c, and d in Example 1, a silicon wafer 9 with a designed metasurface functional element pattern is prepared (the schematic diagram of the product is as follows Figure 2.1 shown);

[0096] b. transfer the pattern on the silicon wafer 9 with the designed metasurface functional primitive pattern to the polymer film 10 (such as PC, PMMA, PEEK, PI, PET, PU, PTFE, PVDF or PDMS, etc.) (the schematic diagram of the product is as Figure 2.2 shown);

[0097] c. The polymer film 10 is separated from the silicon wafer 9, and the pattern on the silicon wafer 9 is transferred to the polymer film 10 to complete the production of the nanoimprint template (the schematic diagram of the product is as follows Figure 2.3 shown);

[0098] d. On the substrate 7 (the substrate 7 is a silicon substrate...

Embodiment 3

[0102] This embodiment provides a method for preparing an optical metasurface optical device based on nanoimprinting, the specific method is:

[0103] a. On the transparent substrate 13, spin-coat a layer of nano-imprint glue 12 with good adhesion to the transparent substrate, and use the Ni metal imprint template or macromolecule with a designed superstructure surface functional element pattern Thin film imprinting template 11 (the material of the polymer film is PC, PMMA, PEEK, PI, PET, PU, PTFE, PVDF or PDMS, etc.) presses the nanoimprinting glue 12, and transfers the pattern to the nanoimprinting glue 12 (product schematic diagram Such as Figure 3.1 shown), the specific transfer process and the cleaning process after the transfer can refer to steps h and i of Example 1;

[0104] b. Utilize the nano-imprint glue 12 as a mask to etch the transparent substrate 13, and the etching depth is the thickness of the metal layer of the designed metasurface functional element (the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com