Separation device for detaching and stacking stamped sheet metal

A separation device and stamping plate technology, applied in the field of sheet metal stamping, can solve the problems of low production efficiency, high safety hazard and high labor intensity, and achieve the effects of reducing moving space, reducing mechanical wear and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

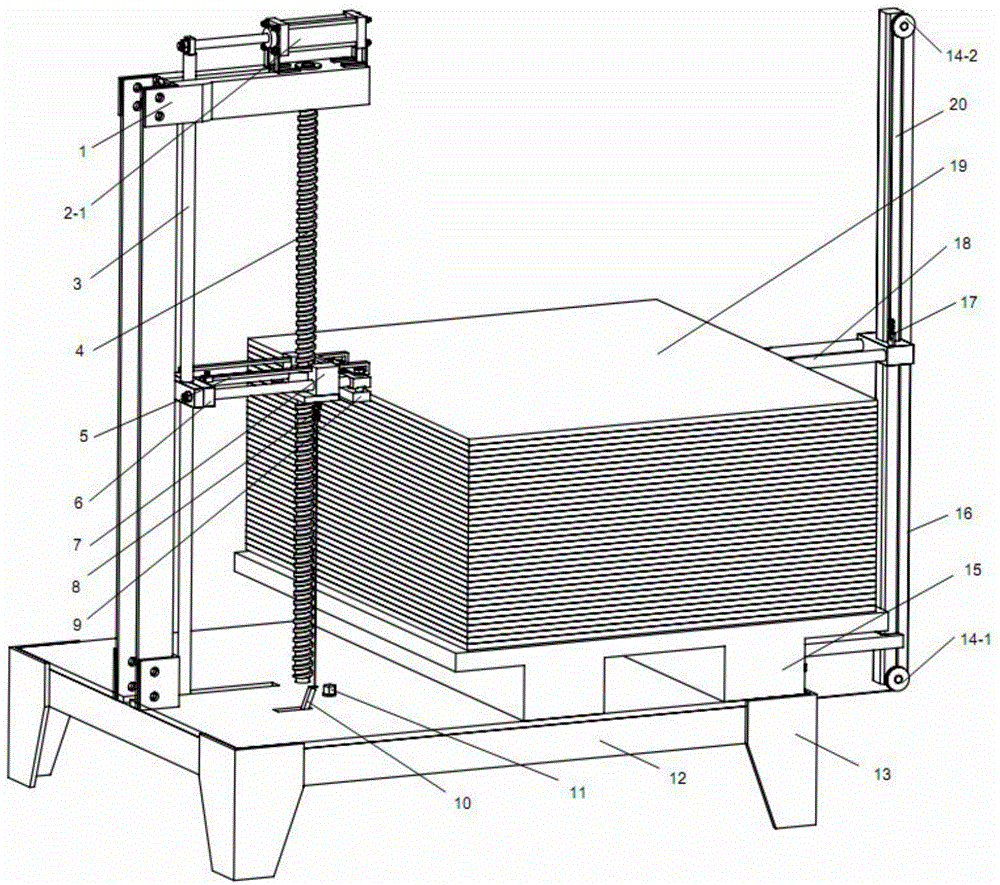

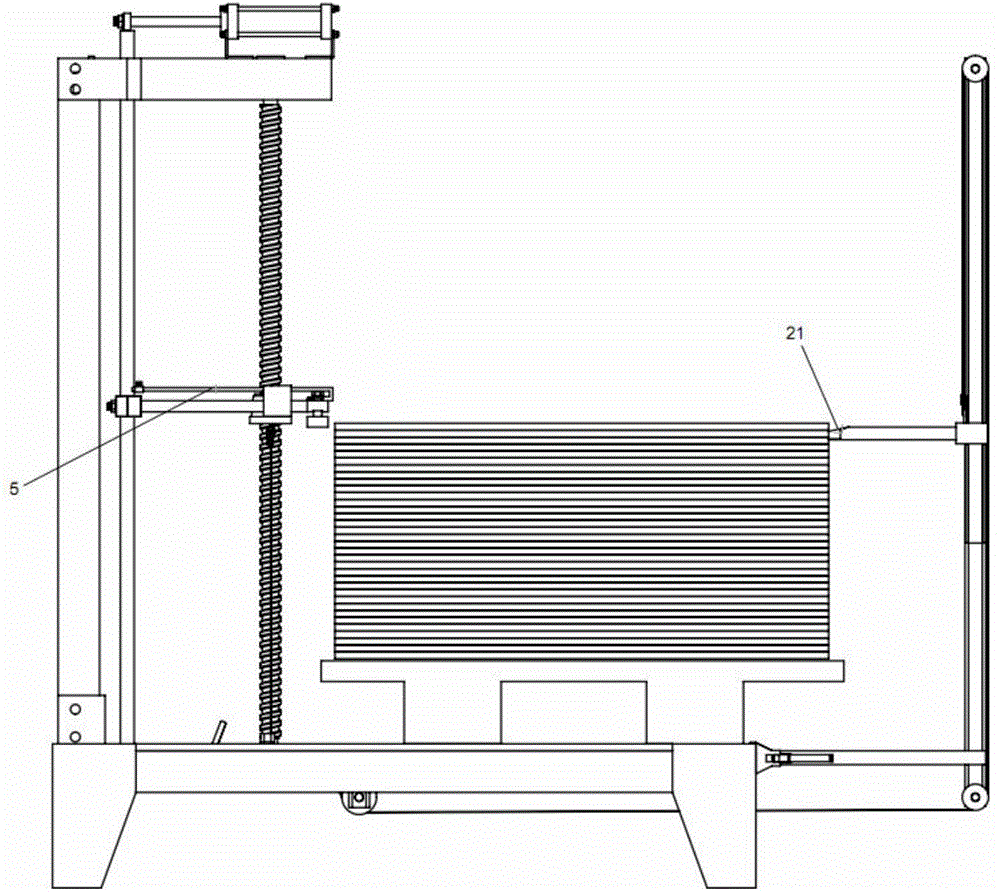

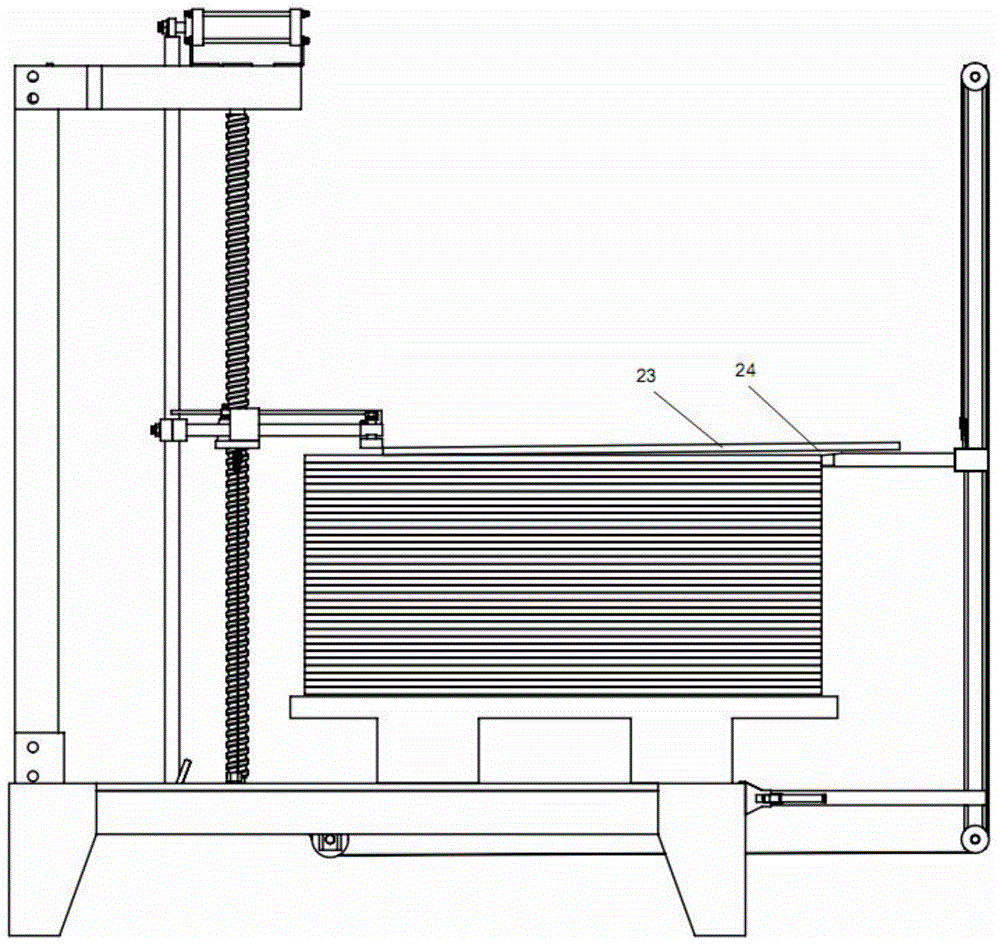

[0039] like Figure 1-Figure 11 As shown, the separating device used for destacking punched sheet materials according to the present invention includes a driving mechanism, a pushing mechanism, a lifting mechanism, a separating mechanism and a support sheet base.

[0040] The driving mechanism includes a joystick 10, a self-locking mechanism 39, a first nut 11, a first cylinder 2-1, a second cylinder 2-2, a large gear 36, a ratchet 27 and a pinion 37, and the pinion 37 is connected to the first nut 11. Connected and meshed with the large gear 36, the large gear 36 is connected with the ratchet 27 through the connecting rod 38, the tooth back of the ratchet 27 is equipped with a non-return pawl 25 and a pawl 29, and the non-return pawl 25 and the pawl 29 are under the action of a spring Mesh with ratchet 27 tooth backs; Self-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com