Environment-friendly and energy-saving water-proof wall material for assembly-type building and production method for wall material

An environmental protection and energy saving technology for construction, applied in the field of construction wall materials, can solve the problems of high board density, aging resistance, poor durability, and large energy loss, and achieve the effect of long service life and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] 本发明一种装配式建筑用环保节能防水型墙材及其生产方法,其具体操作步骤如下:

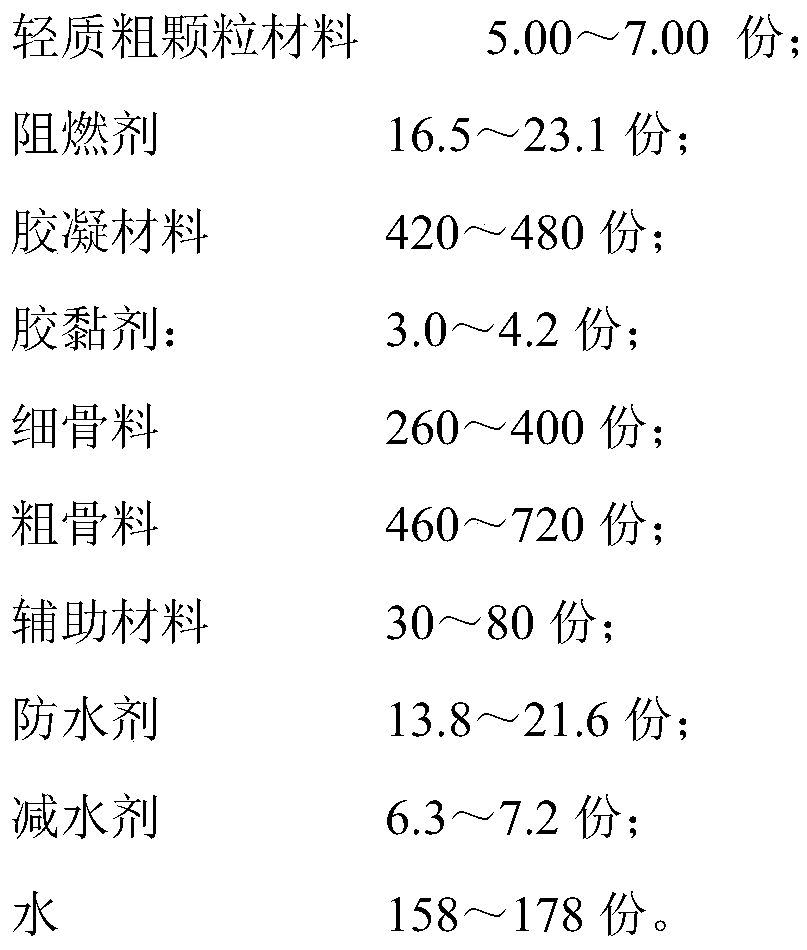

[0113] 第一步是下述材料按质量份比例组合制成一种装配式建筑用环保节能防水型墙材用轻质混凝土。

[0114] 将各原料按如下质量份比例备料,其中:

[0115] 轻质粗颗粒材料:废弃聚苯泡沫颗粒,5.0份。

[0116] 阻燃剂:氢氧化镁,含量≥95%,粒径400目,16.5份。

[0117] 胶凝材料:42.5水泥,480份。

[0118] 胶黏剂:聚醋酸乙烯乳液,3.0份。

[0119] 细骨料:水洗铁尾矿砂,400份。

[0120] 粗骨料:水洗铁尾矿碎石,720份。

[0121] 辅助材料:高炉矿渣微粉,30份。

[0122] 防水剂:甲基硅氧烷,21.6份。

[0123] 减水剂:聚羧酸减水剂,7.2份。

[0124] 水:建筑材料用水,执行相应国家标准规范,170份。

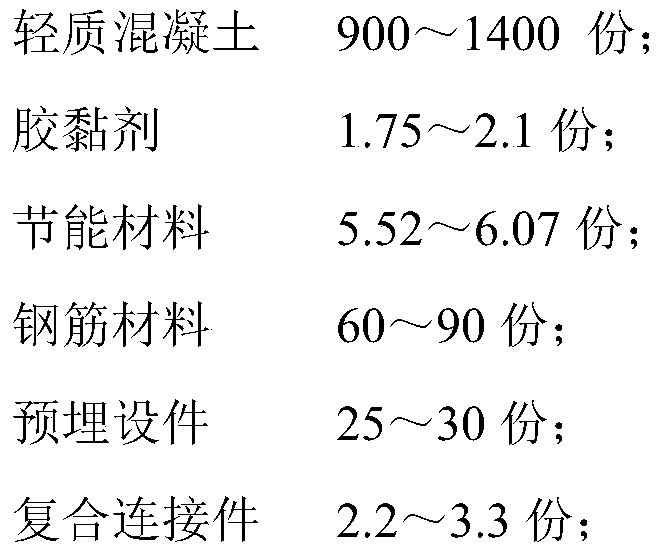

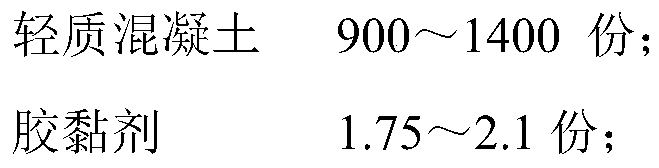

[0125] 第二步一种装配式建筑用环保节能防水型墙材的生产是下述材料按质量份配比组合制成合格品:

[0126] 将各原料按如下质量份比例备料,其中:

[0127] 轻质混凝土:泡沫颗粒混凝土,1400份。

[0128] 胶黏剂:丙烯酸酯乳液,1.75份。

[0129] 节能材料:阻燃型聚苯板,密度20 / m 3 ,5.52份。

[0130] 钢筋:耐腐蚀钢线材,规格:φ6.5mm;70Kg / m 3 .

[0131] 复合连接件:复合断桥型JFRP连接件,规格φ16mm,长度≤150mm,6个 / ㎡。

[0132] 预埋设件:装配用耐腐蚀钢吊环及装配连接件,吊环选用圆钢φ14mm,装配连接件选用板材厚度b:10mm,锚固筋φ10mm,30Kg / m 3 .

[0133] 装饰材料:内墙腻子用量1.2Kg / ㎡,外墙腻子用量1.5Kg / ㎡,防水乳胶漆用量1.5Kg / ㎡。

[0134] 检测结果:实体密度1412.3kg / m 3 ,抗压强度30.13MPa,吸水率<1%,冻融(50次)损失<2%。

Embodiment 2

[0136] 本发明一种装配式建筑用环保节能防水型墙材及其生产方法,其具体操作步骤如下:

[0137] 第一步是下述材料按质量份比例组合制成一种装配式建筑用环保节能防水型墙材用轻质混凝土。

[0138] 将各原料按如下质量份比例备料,其中:

[0139] 轻质粗颗粒材料:废弃聚氨酯泡沫颗粒,5.68份。

[0140] 阻燃剂:氢氧化铝,含量≥95%,粒径400目,18.9份。

[0141] 胶凝材料:42.5水泥,480份。

[0142] 胶黏剂:聚醋酸乙烯乳液,3.41份。

[0143] 细骨料:水洗铁尾矿砂,350份。

[0144] 粗骨料:水洗铁尾矿碎石,635份。

[0145] 辅助材料:高炉矿渣微粉,30份。

[0146] 防水剂:甲基硅酸钾,21.6份。

[0147] 减水剂:聚羧酸减水剂7.2份。

[0148] 水:建筑材料用水,执行相应国家标准规范,170份。

[0149] 第二步一种装配式建筑用环保节能防水型墙材的生产是下述材料按质量份配比组合制成合格品:

[0150] 将各原料按如下质量份比例备料,其中:

[0151] 轻质混凝土:泡沫颗粒混凝土,1235份。

[0152] 胶黏剂:乙丙乳液,1.75份。

[0153] 节能材料:阻燃型聚氨酯板密度22kg / m 3 ,5.8份;

[0154] 钢筋:耐腐蚀钢线材,规格:φ6.5~12mm;70Kg / m 3 .

[0155] 复合连接件:复合断桥型JFRP连接件,规格φ16mm,长度≤150mm,6个 / ㎡。

[0156] 预埋设件:装配用耐腐蚀钢吊环及装配连接件,吊环选用圆钢φ14mm,装配连接件选用板材厚度b:10mm,锚固筋φ10mm,30Kg / m 3 .

[0157] 装饰材料:内墙腻子用量1.2Kg / ㎡,外墙腻子用量1.5Kg / ㎡,防水乳胶漆用量1.5Kg / ㎡。

[0158] 检测结果:实体密度1236.2kg / m 3 ,抗压强度27.68MPa,吸水率<1%,冻融(50次)损失<2%。

Embodiment 3

[0160] 本发明一种装配式建筑用环保节能防水型墙材及其生产方法,其具体操作步骤如下:

[0161] 第一步是下述材料按质量份比例组合制成一种装配式建筑用环保节能防水型墙材用轻质混凝土。

[0162] 将各原料按如下质量份比例备料,其中:

[0163] 轻质粗颗粒材料:废弃酚醛树脂泡沫颗粒,6.36份。

[0164] 阻燃剂:三氧化二锑,含量≥95%,粒径400目,18.08份。

[0165] 胶凝材料:42.5水泥,480份。

[0166] 胶黏剂:醋酸乙烯-乙烯共聚乳液,3.82份。

[0167] 细骨料:水洗铁尾矿砂,310份。

[0168] 粗骨料:水洗铁尾矿碎石,550份。

[0169] 辅助材料:高炉矿渣微粉,30份。

[0170] 防水剂:甲基硅醇钠,21.6份。

[0171] 减水剂:萘系减水剂,7.2份。

[0172] 水:建筑材料用水,执行相应国家标准规范,170份。

[0173] 第二步一种装配式建筑用环保节能防水型墙材的生产是下述材料按质量份配比组合制成合格品:

[0174] 将各原料按如下质量份比例备料,其中:

[0175] 轻质混凝土:泡沫颗粒混凝土,1090份。

[0176] 胶黏剂:丙烯酸酯乳液,1.75份。

[0177] 节能材料:阻燃型酚醛树脂板、密度22kg / m 3 ,6.2份;

[0178] 钢筋:耐腐蚀钢线材,规格:φ5mm;60Kg / m 3 .

[0179] 复合连接件:复合断桥型JFRP连接件,要求规格φ16mm,长度≤150mm,4个 / ㎡。

[0180] 预埋设件:装配用耐腐蚀钢吊环及装配连接件,吊环选用圆钢φ14mm,装配连接件选用板材厚度b:10mm,锚固筋φ10mm,25Kg / m 3 .

[0181] 装饰材料:内墙腻1.2Kg / ㎡,外墙腻子1.5Kg / ㎡,防水乳胶漆1.5Kg / ㎡。

[0182] 检测结果:实体密度1068.3kg / m 3 ,抗压强度25.35MPa,吸水率<1%,冻融(50次)损失<2%。

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com