Fe3O4/CeO2 nanometer composite material, preparation method and application

A technology of nano-composite materials and composite materials, applied in chemical instruments and methods, water/sewage treatment, chemical/physical processes, etc., to achieve strong operability, good application prospects, and good application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

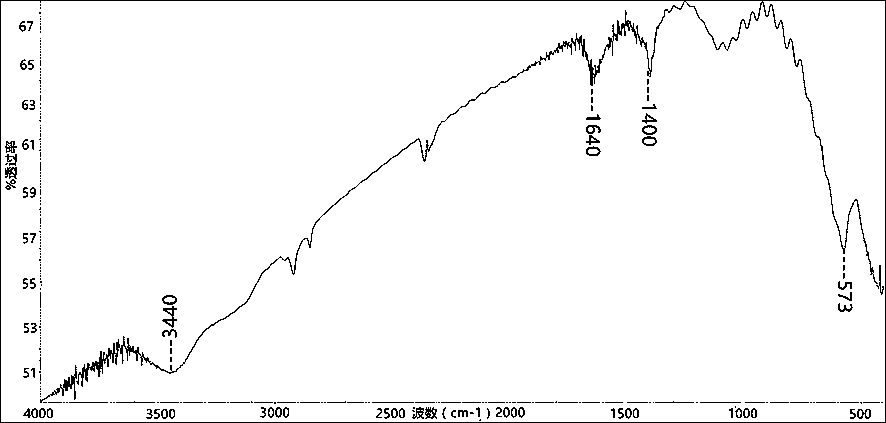

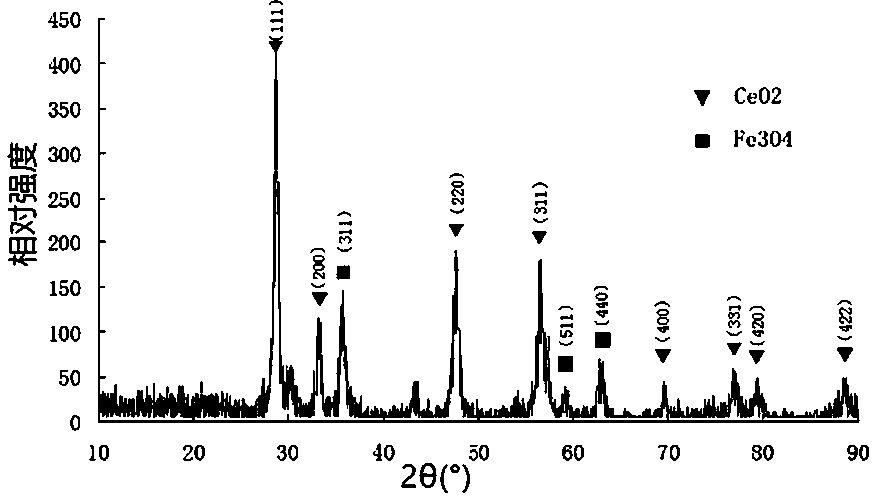

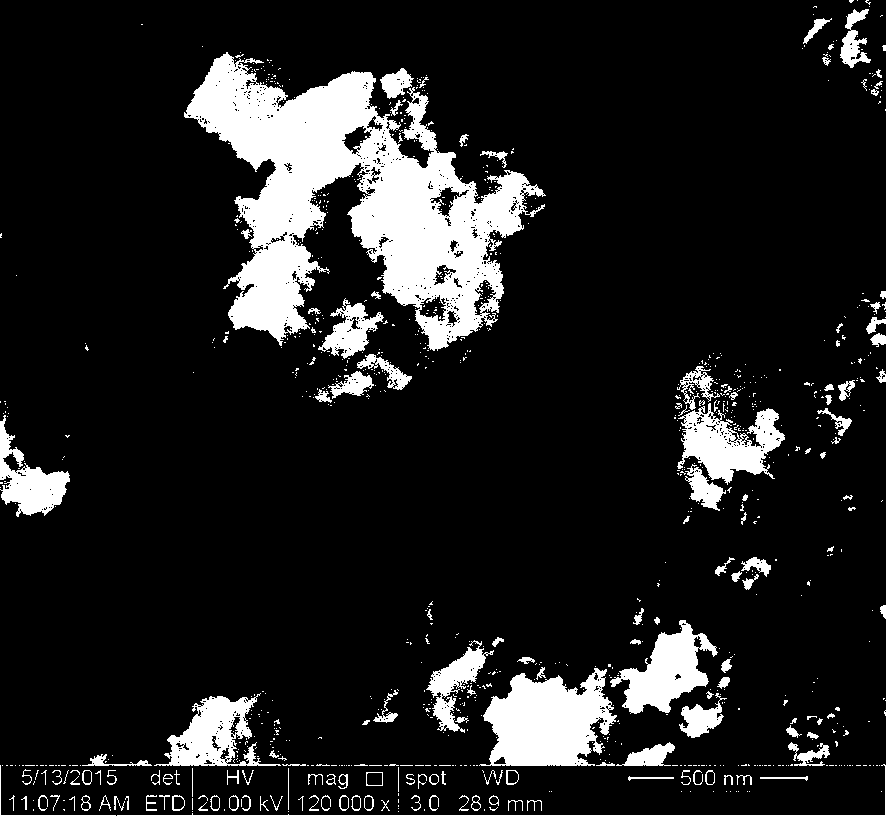

[0070] Fe provided in the present invention 3 o 4 / CeO 2 Nanocomposites are mainly prepared by co-precipitation method. The co-precipitation method means that when the solution contains two or more cations, all kinds of cations exist in the solution in a homogeneous phase. With the addition of the precipitating agent, after the precipitation reaction, a uniform precipitation of various components can be obtained. The co-precipitation method is an important method for preparing composite oxide nanoparticles containing two or more metal elements. It has the advantages of simple preparation process, easy control of preparation conditions, short synthesis period, and low cost. Introduce Fe in the present invention below in conjunction with embodiment 3 o 4 / CeO 2 Preparation of nanocomposites and related testing and identification.

[0071] Fe prepared in this example 3 o 4 / CeO 2 The nanocomposite material is prepared by the following steps:

[0072] (1) Preparation of ...

Embodiment 2

[0106] With the Fe prepared in Example 1 3 o 4 / CeO 2 Based on the nanocomposite material, this example mainly introduces the relevant research on the application of the composite material in wastewater containing p-nitrophenol.

[0107] For the convenience of measuring and evaluating the content of p-nitrophenol in the wastewater solution, the common method is to establish the corresponding relationship between the absorbance and the concentration of p-nitrophenol by using the absorbance method with the help of a spectrophotometer, so as to facilitate the determination of the content of p-nitrophenol in the wastewater, but due to P-nitrophenol exists in different states under different pH conditions, so it needs to be treated differently when using the absorbance method to determine the absorption peak. The following is a brief introduction to the relevant situation when using the absorbance method to determine the content of p-nitrophenol in wastewater.

[0108] Determi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com