Eco-friendly safe reducing agent-based graphene and its preparation and application

A graphene and reducing agent technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as human health hazards, high cytotoxicity, and environmental pollution, and meet the requirements of production and application, biocompatibility Good performance and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

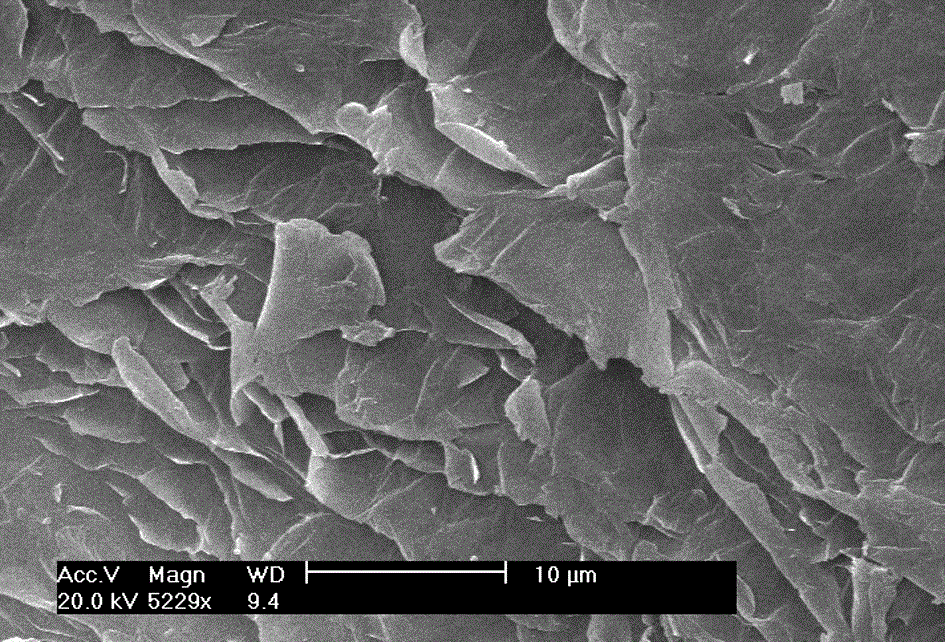

[0025] Weigh 1 g graphite powder and 0.5 g NaNO 3 , slowly add 23 mL of concentrated sulfuric acid to it under the condition of ice-water bath, stir for 30 minutes to make it fully mixed, and make sure that the temperature of the reaction system is not higher than 5°C. 3 g KMnO 4 Slowly add to the reaction system in batches, the feeding process is controlled at about 30 min, the reaction temperature is controlled at 10-15 °C, and the reaction is continued for 1.5 h after the feeding is completed. Then the ice-water bath was removed, and the stirring reaction was continued for 2 h in a constant temperature water bath at 35 °C. Slowly add 100 mL of ultrapure water, and continue to react for 30 min in a constant temperature water bath at 80 °C. Remove the water bath, and slowly add an appropriate amount of hydrogen peroxide while stirring to reduce the excess oxidant until no bubbles are generated. After stirring for 30 min, the layers were separated, and the supernatant was d...

Embodiment 2

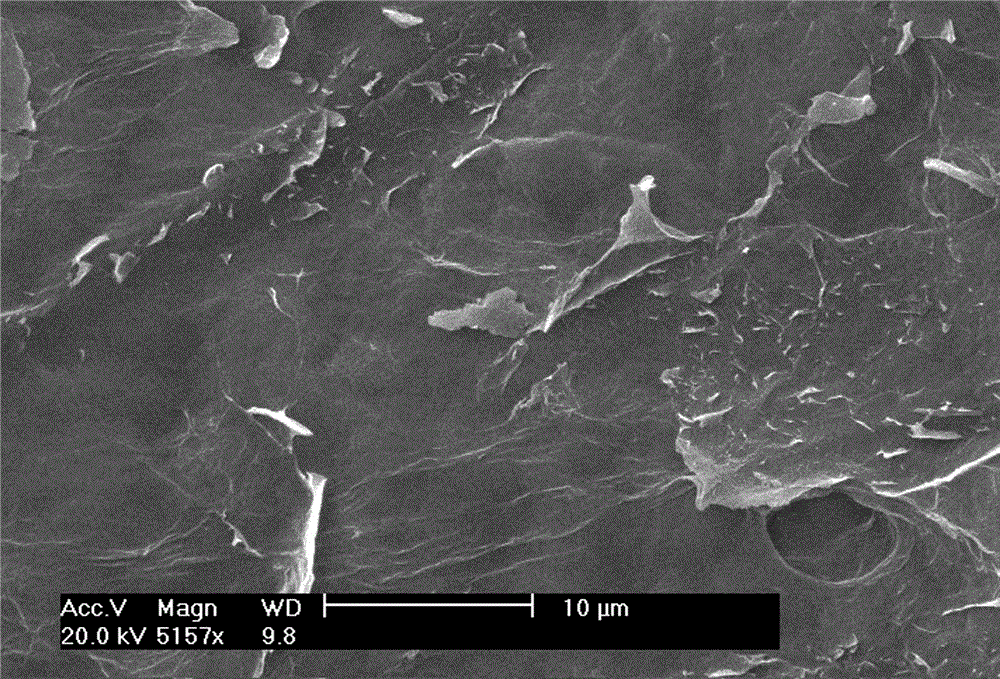

[0028] Weigh 1 g graphite powder and 0.5 g NaNO 3 , slowly add 23 mL of concentrated sulfuric acid to it under the condition of ice-water bath, stir for 30 minutes to make it fully mixed, and make sure that the temperature of the reaction system is not higher than 5°C. 3 g KMnO 4 Slowly add to the reaction system in batches, the feeding process is controlled at about 30 min, the reaction temperature is controlled at 10-15 °C, and the reaction is continued for 1.5 h after the feeding is completed. Then the ice-water bath was removed, and the stirring reaction was continued for 2 h in a constant temperature water bath at 35 °C. Slowly add 100 mL of ultrapure water, and continue to react for 30 min in a constant temperature water bath at 80 °C. Remove the water bath, and slowly add an appropriate amount of hydrogen peroxide while stirring to reduce the excess oxidant until no bubbles are generated. After stirring for 30 min, the layers were separated, and the supernatant was d...

Embodiment 3

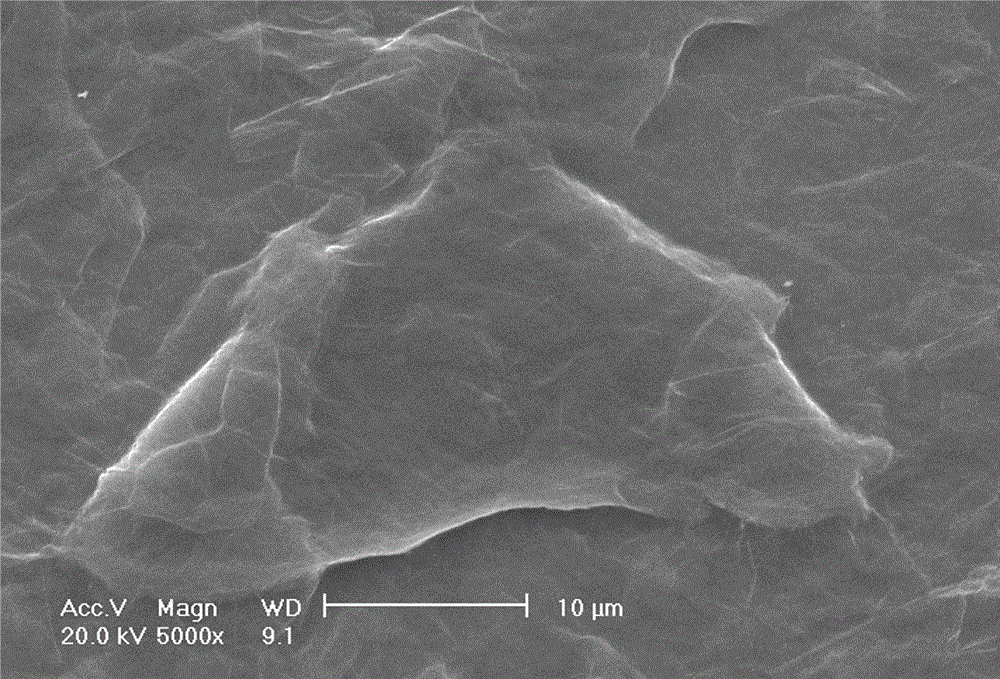

[0031] Weigh 1 g graphite powder and 0.5 g NaNO 3 , slowly add 23 mL of concentrated sulfuric acid to it under the condition of ice-water bath, stir for 30 minutes to make it fully mixed, and make sure that the temperature of the reaction system is not higher than 5°C. 3 g KMnO 4 Slowly add to the reaction system in batches, the feeding process is controlled at about 30 min, the reaction temperature is controlled at 10-15 °C, and the reaction is continued for 1.5 h after the feeding is completed. Then the ice-water bath was removed, and the stirring reaction was continued for 2 h in a constant temperature water bath at 35 °C. Slowly add 100 mL of ultrapure water, and continue to react for 30 min in a constant temperature water bath at 80 °C. Remove the water bath, and slowly add an appropriate amount of hydrogen peroxide while stirring to reduce the excess oxidant until no bubbles are generated. After stirring for 30 min, the layers were separated, and the supernatant was d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com