Step-by-step hoisting construction method for prefabricated beam of multilayer fabricated industrial factory building

A technology for industrial workshops and construction methods, which is applied to building components, floor slabs, buildings, etc., can solve problems affecting the development of construction plans, and achieve the effect of shortening the hoisting period and speeding up production and operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the content of the present invention easier to understand clearly, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

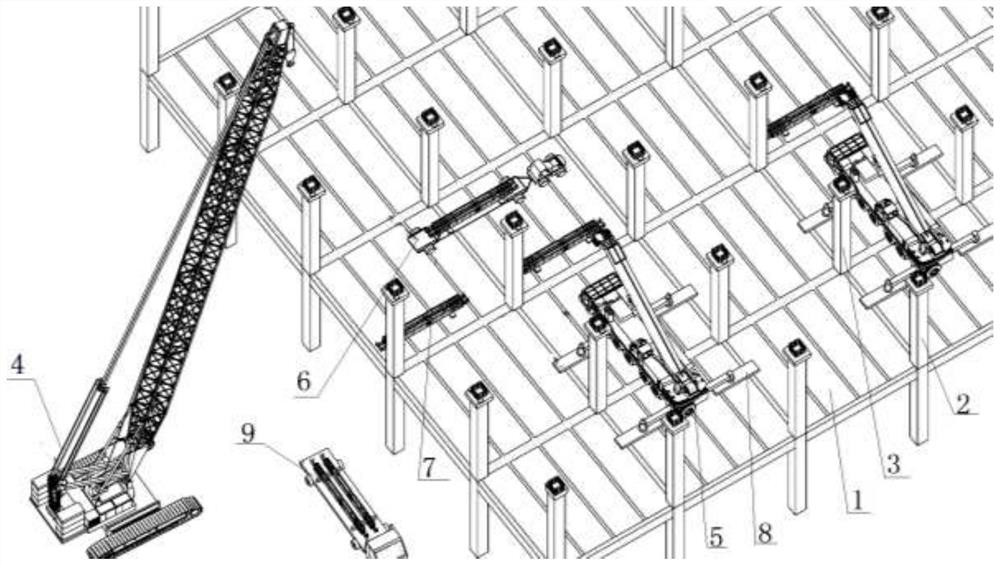

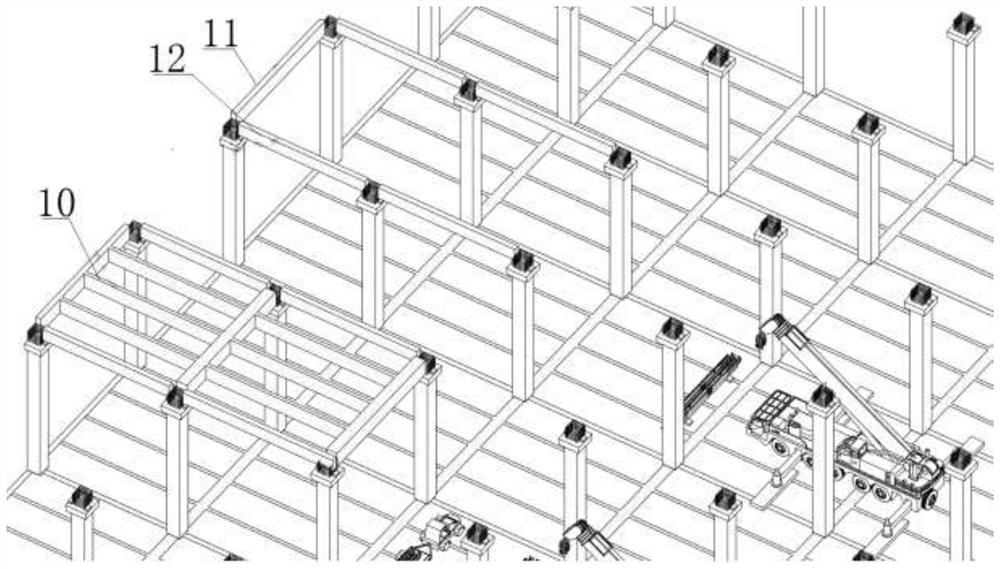

[0013] see figure 1 with figure 2 , a step-by-step hoisting technology for prefabricated beams of multi-storey prefabricated industrial plants, including the following construction steps: firstly, the floor slab laying of the second or more floors 1 is completed, steel bar binding, concrete pouring and emery wear-resistant ground construction. The specific operation steps are as follows: after the initial setting of the floor concrete, apply emery wear-resistant aggregate directly on the fresh concrete surface, mechanically polish the surface and maintain it, and treat it as a curing agent. Then construct reinforced concrete columns on the second floor or above. The side-span column 2 adopts the overall hoisting construction technology of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com