An asymmetric construction method and control method for the main truss of a long-span flexible suspension bridge

A main truss and long-span technology, applied in the direction of suspension bridges, bridges, bridge construction, etc., can solve the problem that the main truss cannot be hoisted symmetrically, achieve bridge engineering technology satisfaction, improve management level, and save the hoisting period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

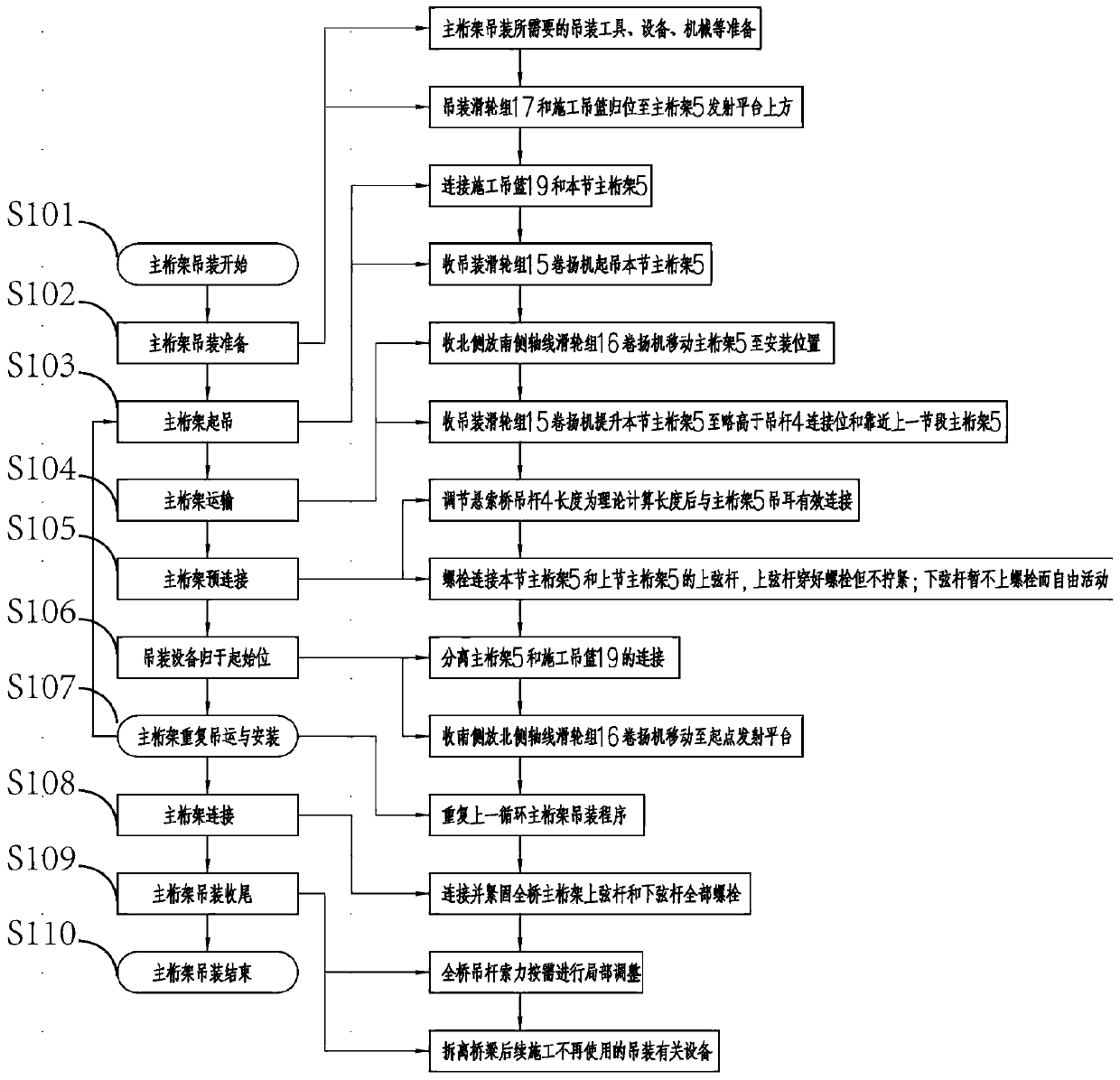

[0048] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

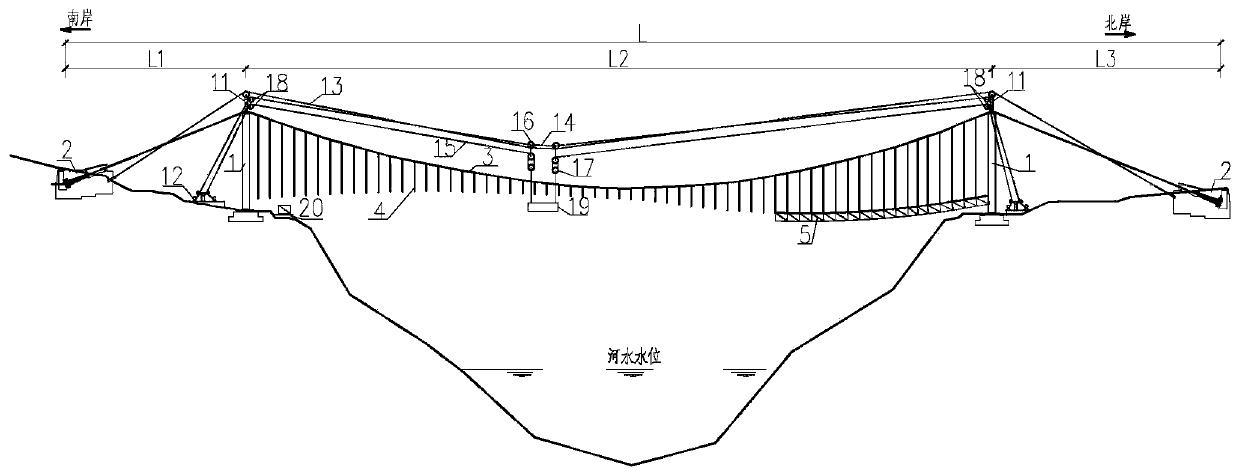

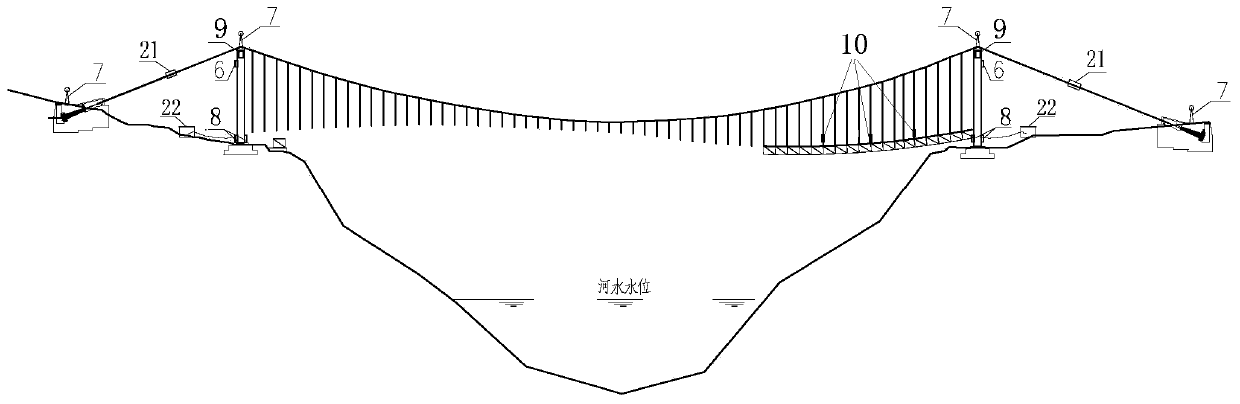

[0049] Such as figure 1 As shown, the asymmetric construction device for the main truss of a large-span flexible suspension bridge provided by the embodiment of the present invention includes: tower column 1, ground anchor 2, main cable 3, boom 4, main truss 5, tower platform 11, hoist and ground anchor 12. Construction load-bearing cable 13, cable pulley hoist running rope 14, hoisting pulley hoist running rope 15, cable pulley 16, hoisting pulley block 17, steering pulley 18, construction basket 19, main truss launching hoisting platform 20.

[0050] figure 1 The span parameters of the medium and long-span flexible su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com