Anti-explosion pressure-relief wall construction method for large-scale industrial factory building

A large-scale industry and construction method technology, applied in the direction of construction, building components, building structure, etc., can solve the problems of difficult construction of explosion-proof pressure relief walls, difficult construction, and difficult to guarantee project quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

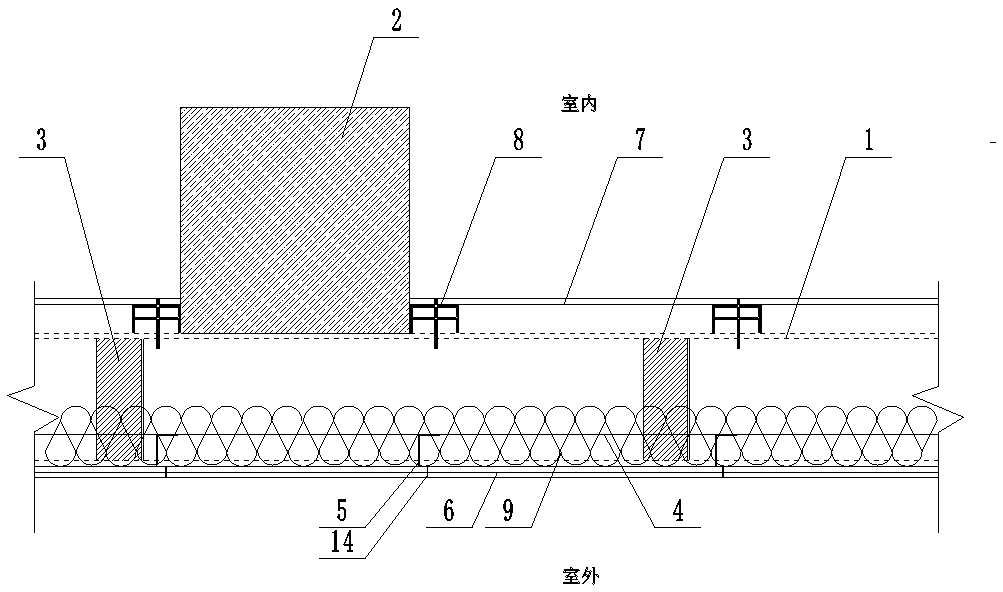

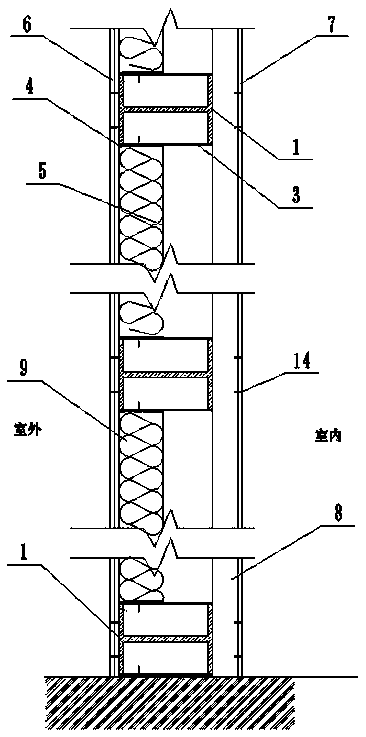

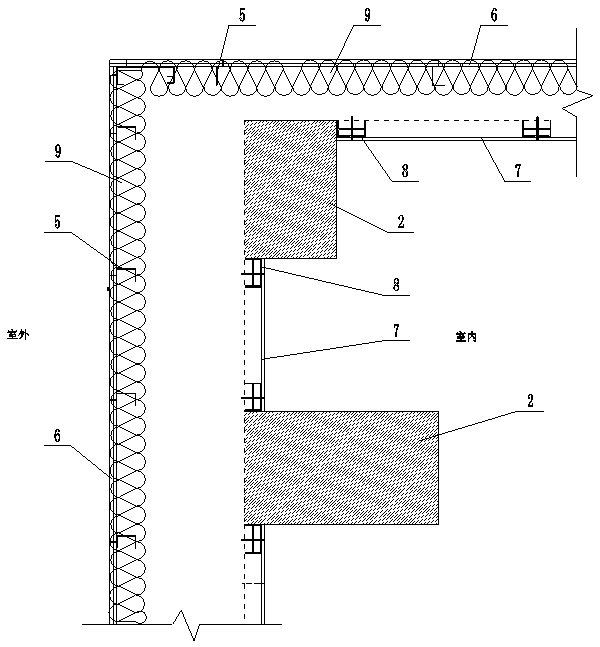

[0029] A typical embodiment of the present invention provides a method for constructing an explosion-proof and pressure-relief wall of a large industrial factory building, which includes the following steps.

[0030] Step 1, purlin 1 construction

[0031] The purlin 1 is mainly welded and fixed to the embedded parts of the frame structure (such as figure 1 On the original structural column 2) shown in , the angle steel 3 used to fix the keel is welded on the ground before the purlin 1 is installed. The angle steel is welded on the upper and lower sides of the purlin, avoiding high-altitude welding construction, ensuring quality and construction safety.

[0032] Step two, keel installation

[0033] The horizontal keel 4 on the outside of the wall is connected to the purlin 1 through the angle steel 3 and fixed between the upper and lower purlins 1, and the outermost line of the horizontal keel 4 on the outer side of the wall is in the same plane as the outermost line of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com