Industrial factory building steel structure hoisting device and construction method thereof

A technology for hoisting devices and industrial plants, which is applied in hoisting devices, bottom support structures, lifting equipment braking devices, etc., can solve the problems of large shaking range of steel beams, difficulty in controlling steel beams, inconvenient installation and fixing of steel beams, etc., to achieve Improves stability and reduces damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Attached to the following Figure 1-3 This application will be described in further detail.

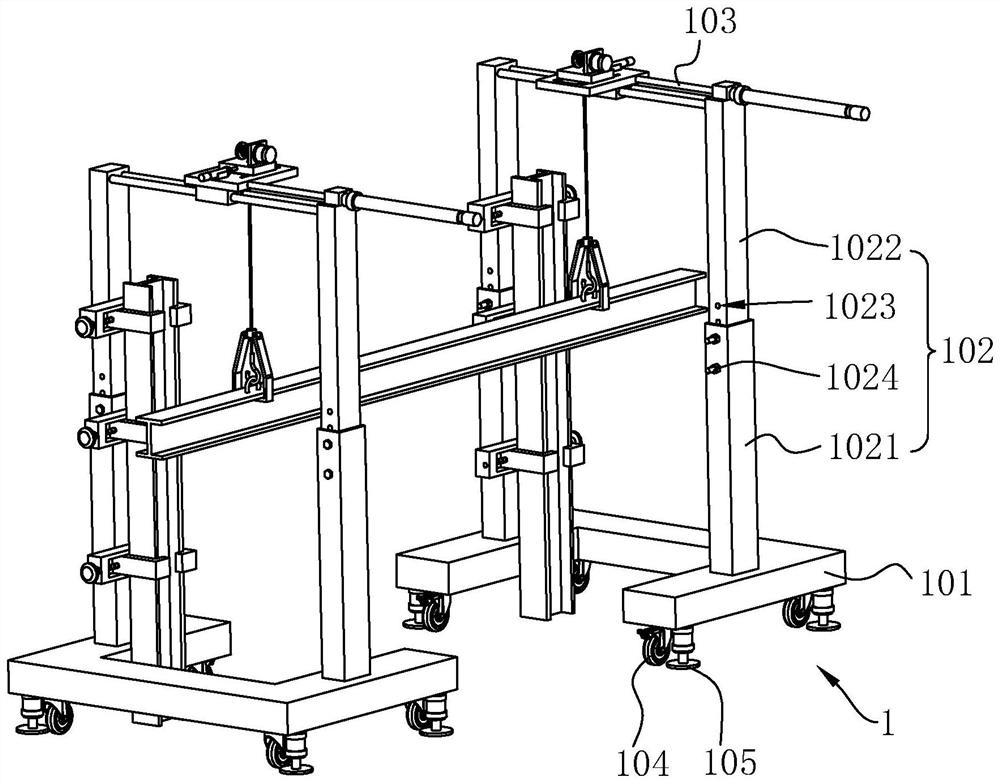

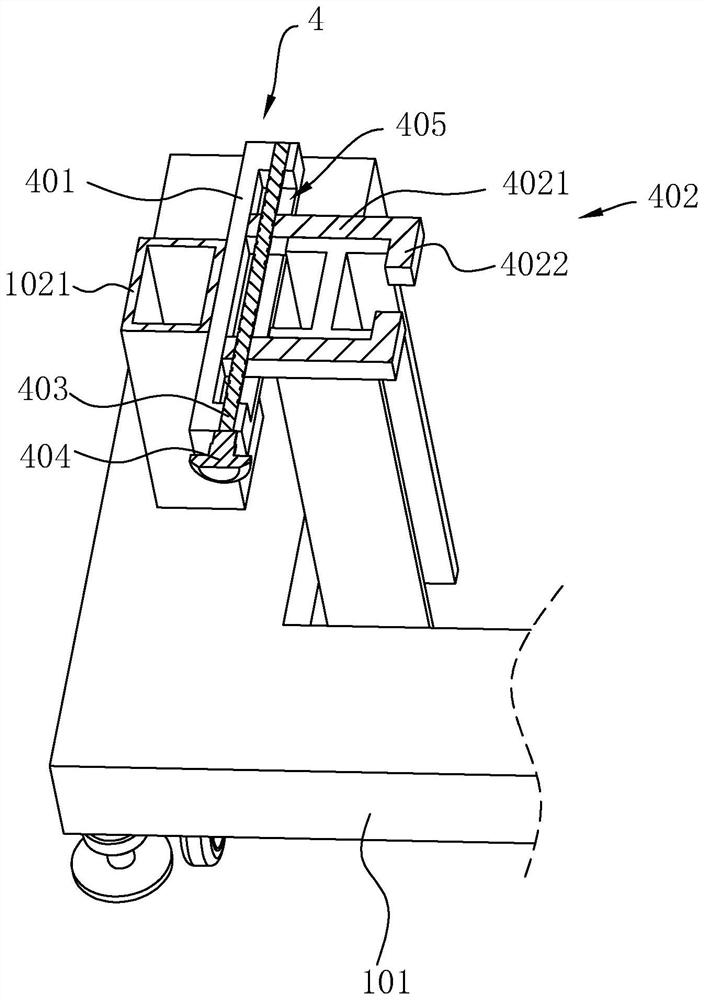

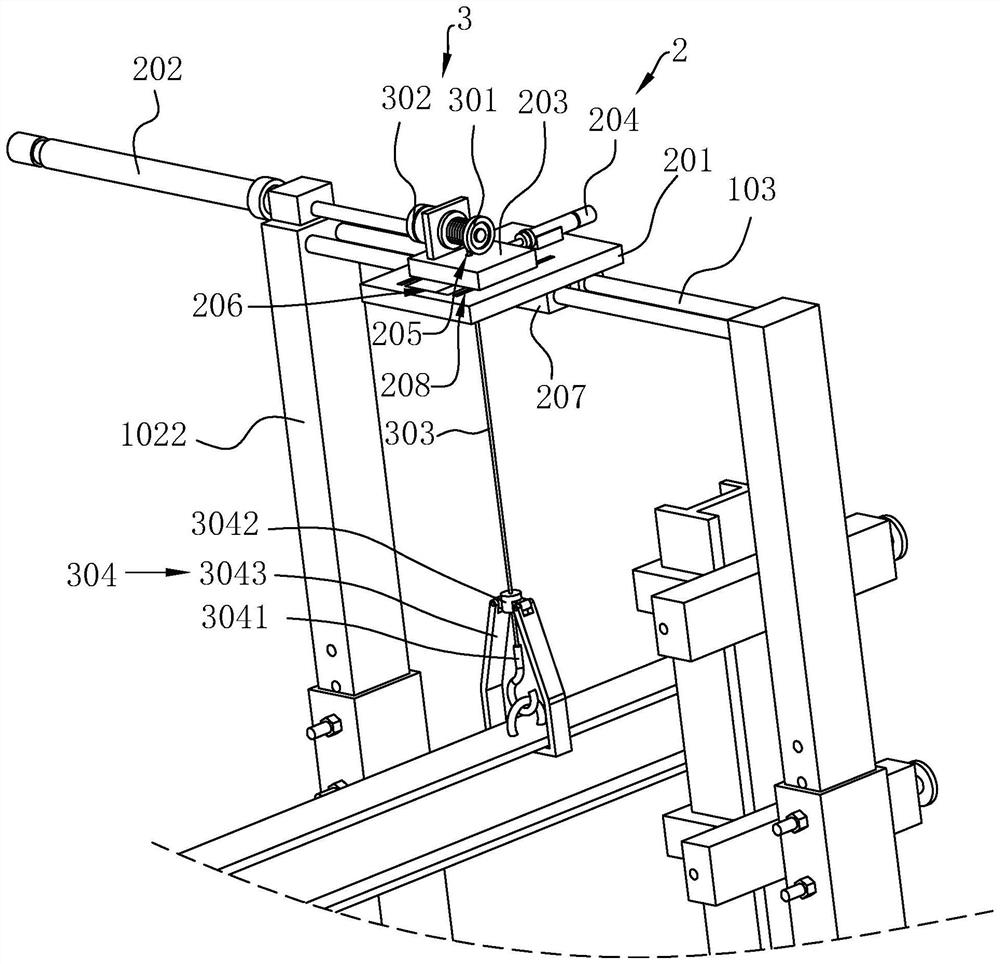

[0039] The embodiment of the present application discloses a hoisting device for a steel structure of an industrial workshop. refer to figure 1The hoisting device for the steel structure of the industrial workshop comprises a base 1, a firm mechanism 4 for connecting steel columns, a hoisting mechanism 3 for hoisting a steel beam, and an adjustment mechanism 2 for adjusting the position of the steel beam. The base 1 includes a seat body 101, two vertical bars 102 and two horizontal bars 103. The two vertical bars 102 are welded and fixed at both ends of the seat body 101, and the two horizontal bars 103 are welded and fixed between the two vertical bars 102. The two horizontal bars 103 are parallel to each other. The seat body 101 is surrounded by three square steels to form a rectangular seat body 101 with an opening on one side, and the vertical rod 102 is welded and fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com