Method for adjusting axis deviation of industrial factory building edge foundation heavy column

A technology for cup mouth foundation and industrial plant, which is applied in construction, building structure, construction material processing, etc., can solve problems such as concrete damage of cup mouth foundation, poor appearance of cup mouth foundation, difficulty in precision control, etc., so as to improve the quality , The effect of shortening the construction time and improving the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

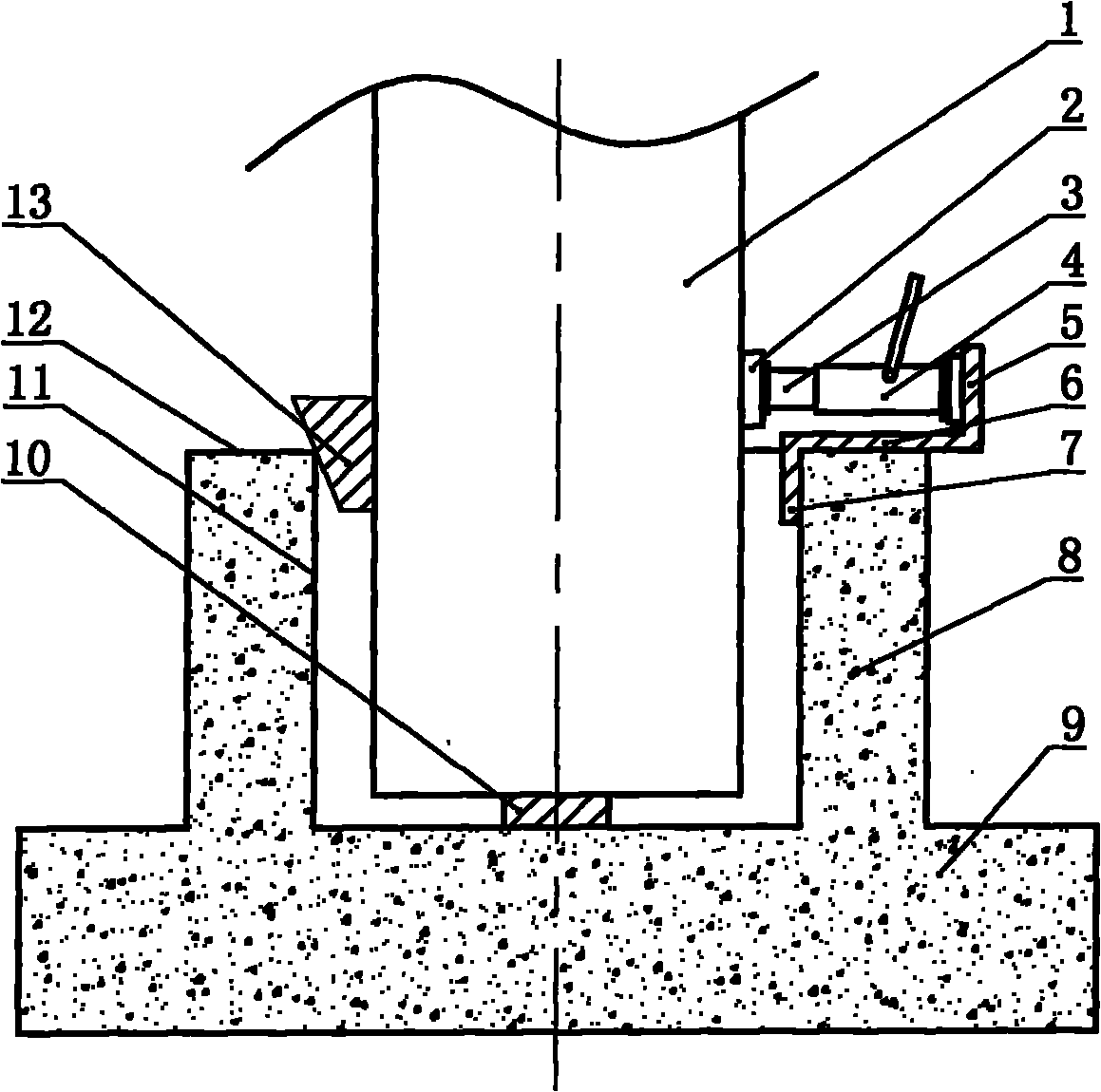

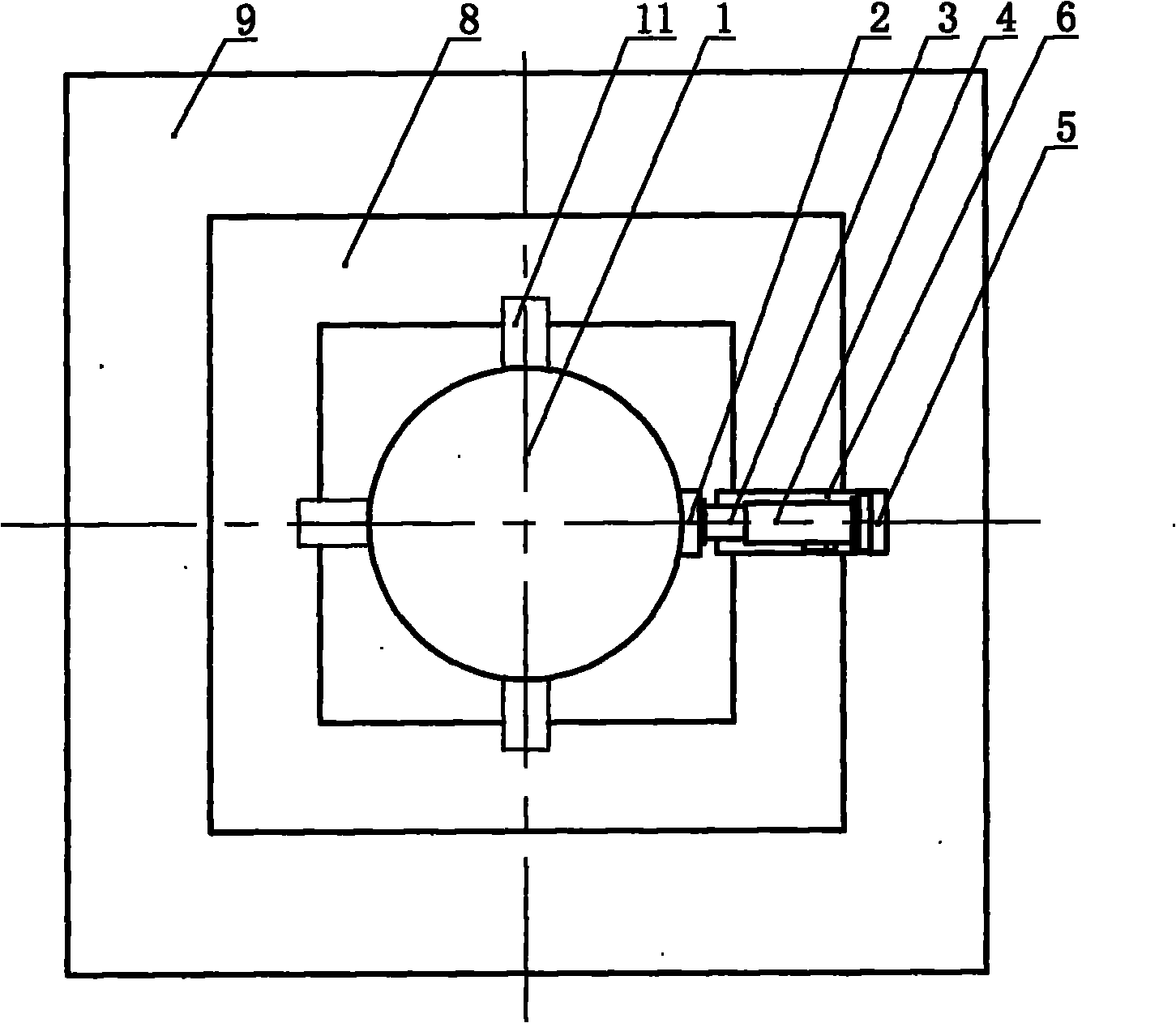

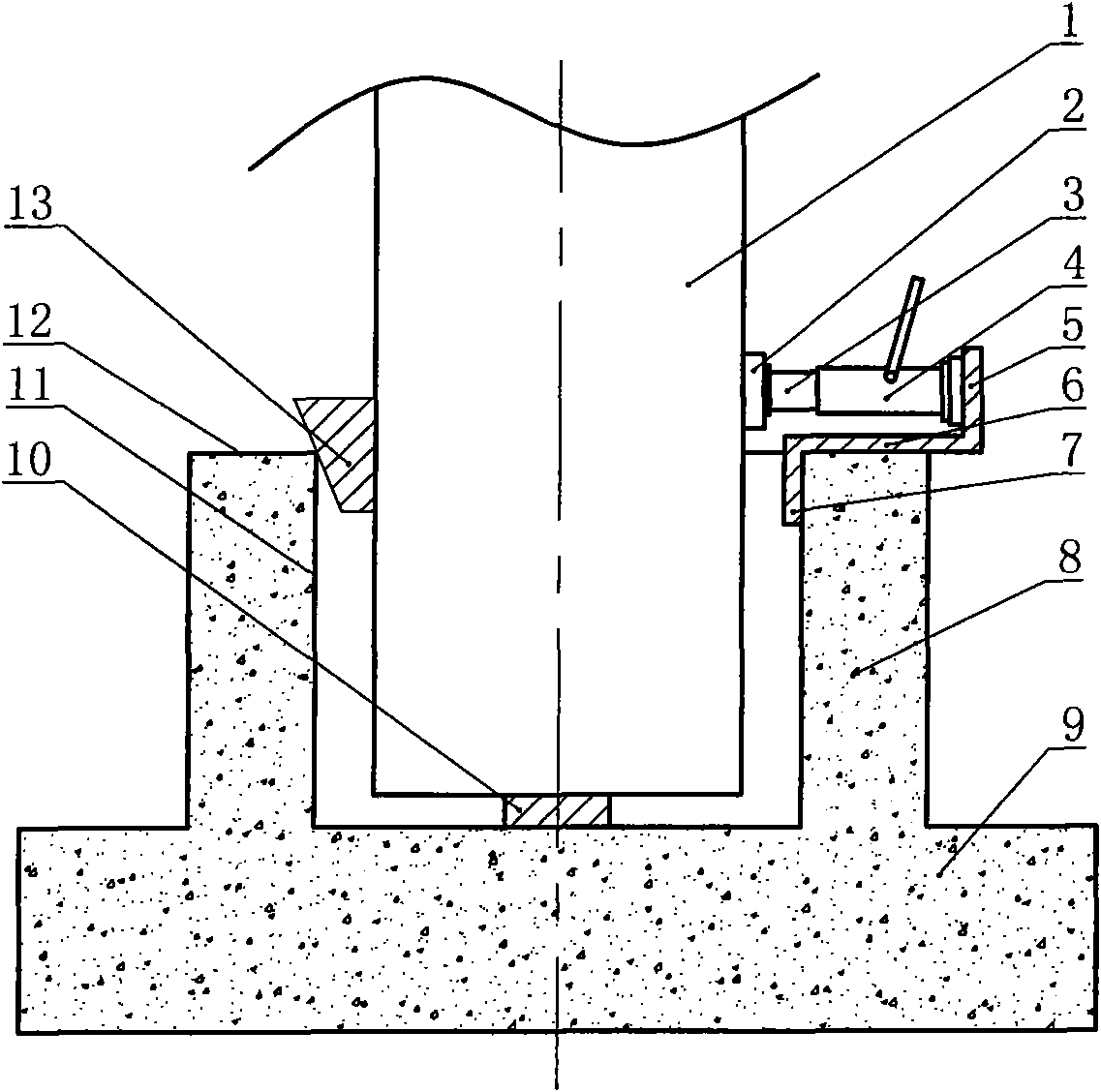

[0018] A method for adjusting the axis deviation of a heavy-duty column at the base of an industrial factory building, the steps of which are: (1) hoisting the heavy-duty column 1 into the base of the base 9 with a crane, the base of the base is formed by one-time pouring of concrete, and the base of the base protrudes The four-wall section of part 8 becomes rectangle or square, and present embodiment adopts square, and after hoisting is finished, the steel wire rope that is used for binding heavy-duty column is loosened, but does not unhook, so that the adjustment of heavy-duty column and protection; (2) use theodolite Measure the verticality and axis offset of the heavy-duty column to obtain the accurate offset size; (3) adjust the axis off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com