Light-steel light-concrete structural system and construction method thereof

A technology of light concrete and construction methods, which is applied in the direction of building structure and construction, can solve the problems of limited building scale, a large amount of construction waste, insufficient maintenance costs, etc., achieve reduced steel consumption, low overall cost, and solve fire and fire prevention problems. rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

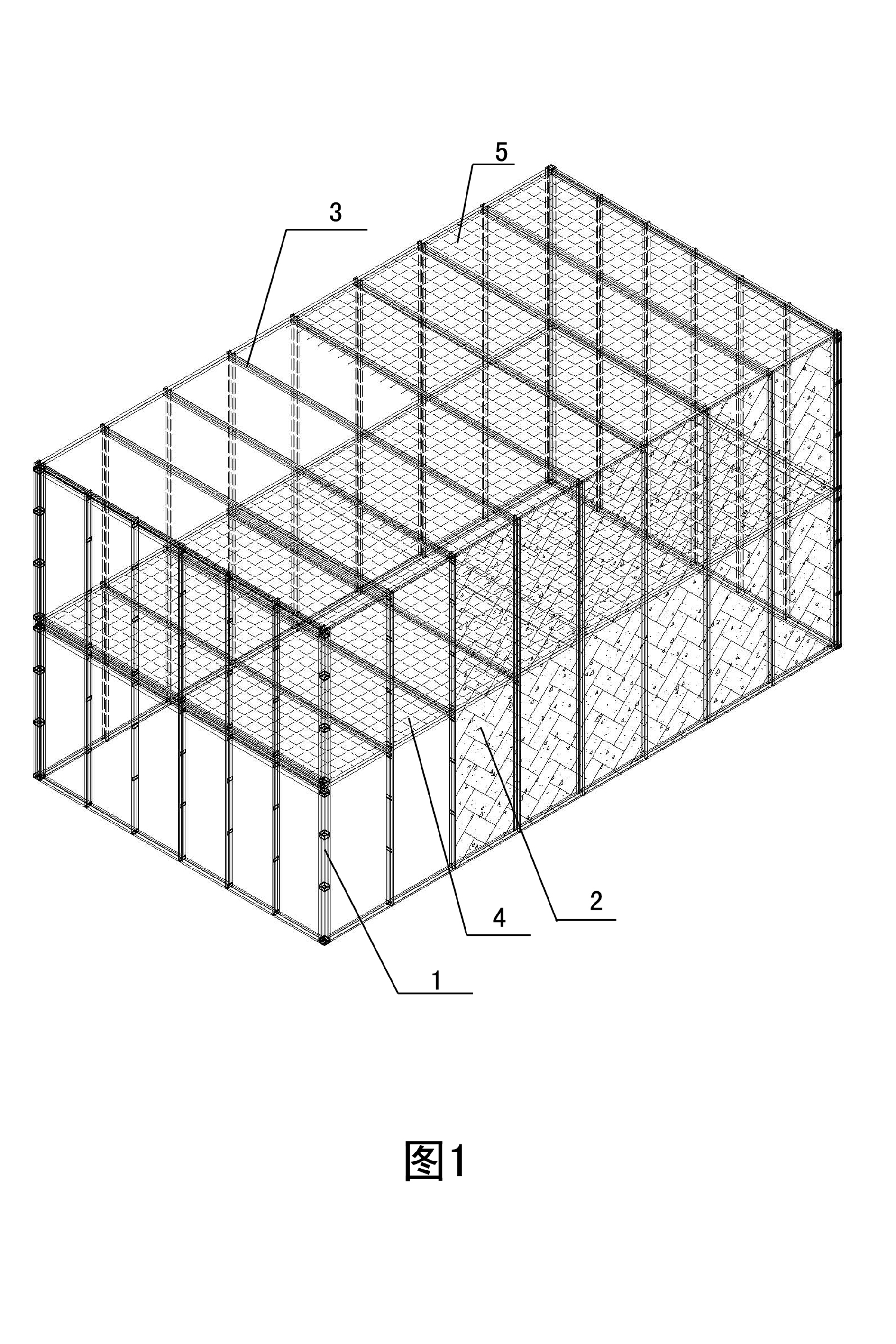

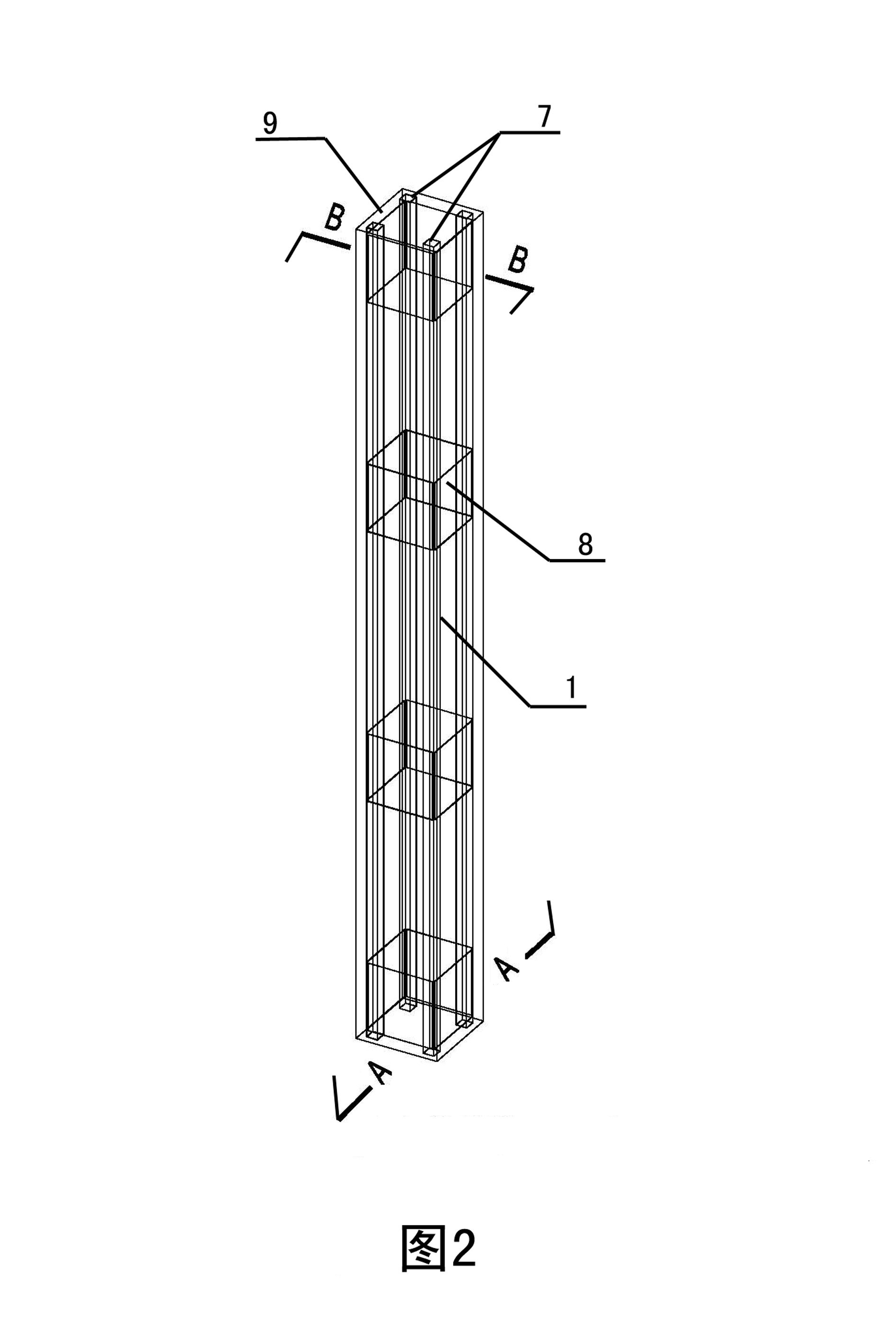

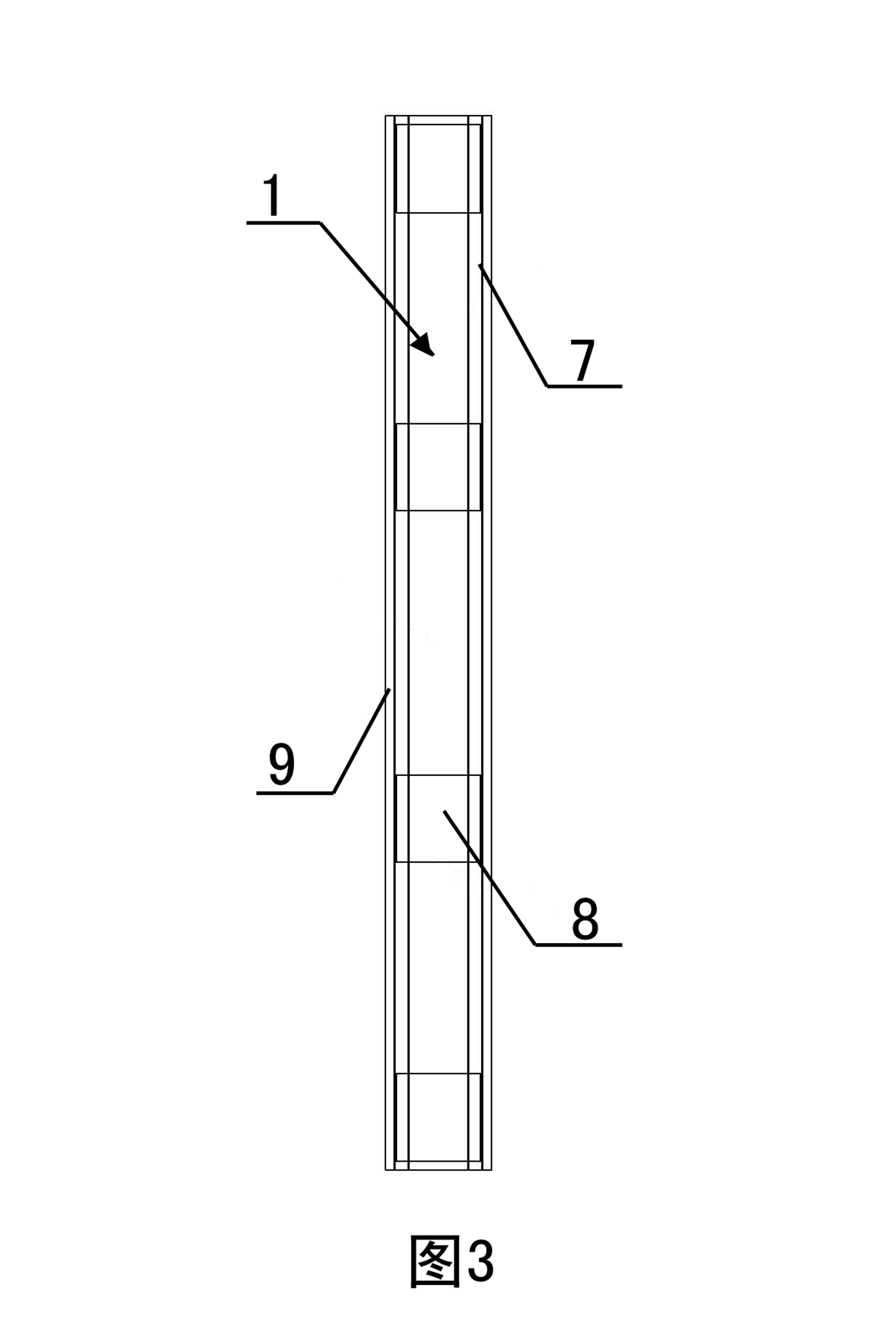

[0044] Examples see Figure 1 to Figure 16As shown, a light steel light concrete structure system is composed of light steel light concrete column 1, light steel light concrete wall 2, lattice light steel sheet beam 3, floor slab 4 and roof slab 5, and floor slab 4 and roof slab 5 overlap On the side of the column 1 or the wall 2, the floor slab 4 and the roof panel 5 are cast-in-place integrated with the beam, and the wall is located between two adjacent columns. The light steel frame composed of connecting pieces 8 and the light concrete 9 that completely wraps the light steel frame are cast in-situ. The light steel 7 is distributed with connecting pieces 8 at intervals along its height, and the light concrete 9 in the column constrains the plane of the light steel frame. The buckling deformation inside, the connecting piece 8 constrains the buckling deformation outside the plane; the wall is a light steel light concrete wall panel 2, which is composed of a group of lattice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com