Local reinforcing method of circular reinforced concrete column

A reinforced concrete column and local reinforcement technology, which is applied in construction, building maintenance, building construction, etc., can solve the problems of poor co-workability of new and old concrete, low performance utilization rate of outsourced steel, and small improvement in structural plasticity. The effect of reducing the waste of natural and social resources, high reinforcement reliability, and reducing the cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described by way of example in conjunction with the accompanying drawings,

[0026] The invention provides. A local reinforcement method for a circular reinforced concrete column, comprising the following steps:

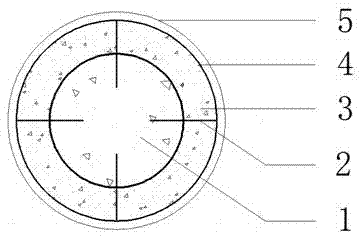

[0027] a. Install symmetrical reinforcement 2 at the place where the original reinforced concrete column 1 needs to be reinforced;

[0028] b. A jacket thin-walled steel pipe 4 is arranged on the periphery of the reinforced concrete column 1, and the jacket thin-walled steel pipe 4 wraps the reinforced concrete column 1 and the planting bar 2;

[0029] c Wrap FRP cloth 5 outside the thin-walled steel pipe 4 of the jacket, and after the adhesive of the FRP cloth 5 is cured, pour self-compacting new concrete or inorganic grouting material mixed with steel fibers between the thin-walled steel pipe 4 and the reinforced concrete column 1 .

[0030] The outer thin-walled steel pipe 4 coincides with the geometric center of the reinforced con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com