Energy-saving open-cell foamed glass and preparation method thereof

An open-cell foam, energy-saving technology, applied in the field of sound-absorbing material preparation, can solve the problems of limited production cost, wide application, backward process, technology, equipment, low single-line production capacity of foam glass, etc., and achieves good sound-absorbing effect, beautiful appearance, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

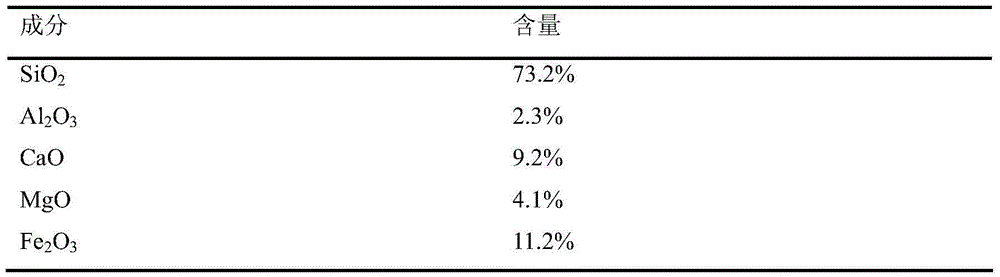

Method used

Image

Examples

Embodiment 1

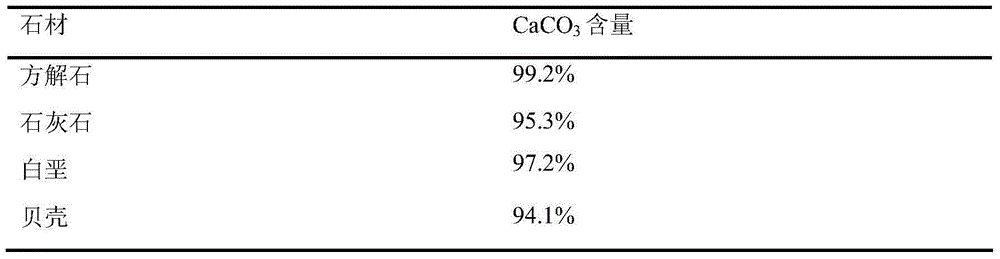

[0048] First, weigh 93% of the total weight of discarded flat glass, 5% of crushed limestone, 1% of coarse borax, and 1% of zinc white; use a ball mill to crush each component to 140-200 mesh, and make each The components are mixed evenly; then, after putting the mixture into the mold, put the mold into the furnace and fire according to the following procedure: from room temperature to 400°C at a heating rate of 5°C / min, and hold for 25 minutes; then at 10°C / min Raise the heating rate to 820°C and keep it warm for 25 minutes; then cool it down to 600°C at a cooling rate of 20°C / min and keep it warm for 30 minutes; then cool it down to room temperature at a cooling rate of 0.7°C / min to complete the open-cell foam glass product. The parameters of the open-cell foam glass prepared by this method are respectively: bulk density 144kg / m 3 The compressive strength is 0.6MPa; the open porosity is 65%; the sound absorption coefficient measured by the wave tube method is: low frequency ...

Embodiment 2

[0050] First, weigh 93% of the total weight of discarded broken patterned glass, 5% of broken chalk, 1% of coarse borax, and 1% of zinc white; take a ball mill to crush each component to 140-200 mesh, and make Mix the components evenly; then, after putting the mixture into the mold, put the mold into the furnace and fire it according to the following procedure: from room temperature to 400°C at a heating rate of 3°C / min, and hold for 20 minutes; then at 10°C / min Min heating rate is raised to 800°C and kept for 25 minutes; then cooled to 600°C at a cooling rate of 20°C / min and kept for 30 minutes; then cooled to room temperature at a cooling rate of 0.8°C / min to complete the open-cell foam glass product. The parameters of the open-cell foam glass prepared by this method are respectively: bulk density 147kg / m 3 The compressive strength is 0.65MPa; the open porosity is 67%; the sound absorption coefficient measured by the wave tube method is: low frequency (100-125HZ) 0.44, high ...

Embodiment 3

[0052] First, weigh 93% of the total weight of discarded broken bottle glass, 5% of shells, 1% of coarse borax, and 1% of zinc white; use a ball mill to crush each component to 140-200 mesh, and make each The components are mixed evenly; then, after putting the mixture into the mold, put the mold into the furnace and fire according to the following procedure: from room temperature to 400°C at a heating rate of 8°C / min, and hold for 30 minutes; then at 10°C / min Raise the heating rate to 830°C and keep it warm for 25 minutes; then cool it down to 600°C at a cooling rate of 20°C / min and keep it warm for 30 minutes; then cool it down to room temperature at a cooling rate of 0.7°C / min to complete the open-cell foam glass product. The parameters of the open-cell foam glass prepared by this method are respectively: bulk density 149kg / m 3 The compressive strength is 0.64MPa; the open porosity is 64%; the sound absorption coefficients measured by wave tube method are: low frequency (10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com