Novel prefabricated wall plate and building external wall assembled by same

A technology of prefabricated wall panels and building exterior walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

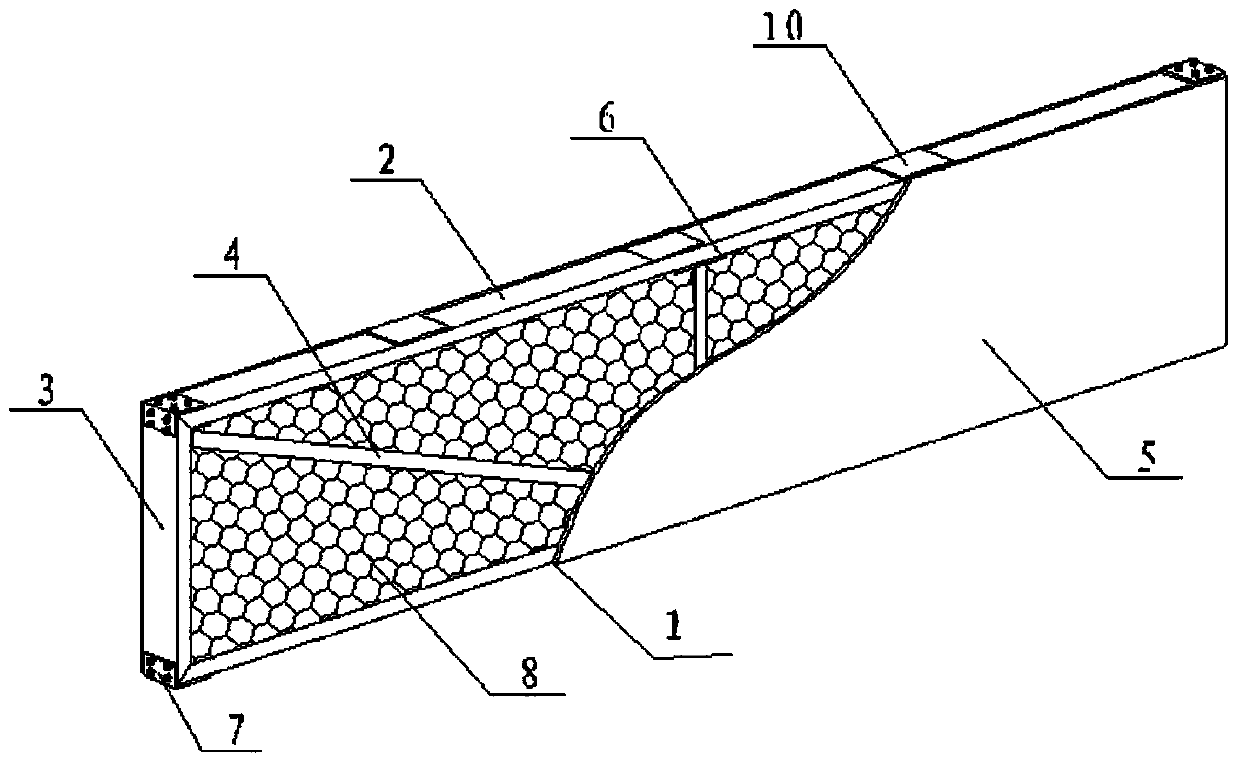

[0060] A novel prefabricated wall panel 1, such as figure 1 As shown, it includes a wall panel steel skeleton, which includes a main rib 2, an auxiliary rib 3 and a reinforcing rib 4; the auxiliary rib 3 is perpendicular to the main rib 2, and the two ends of the auxiliary rib 3 are respectively connected to the upper and lower The two main ribs 2 are connected; the two ends of the reinforcing rib 4 are connected with the main rib 2 and the auxiliary rib 3; panels 5 are installed on both sides of the steel skeleton of the wall panel, and there is an insulating layer between the panels 5. The insulation layer is equipped with a core material 8, the main rib 2 is equipped with an anti-seismic connecting plate 10, the length of the anti-seismic connecting plate 10 is 100-200mm, and the width is 5-10mm less than the thickness of the whole prefabricated wallboard; The interval between the connection boards is 1-1.5 meters.

[0061] In this embodiment, the main ribs 2, auxiliary ri...

Embodiment 2

[0069] A kind of novel prefabricated wallboard, this wallboard is basically the same as that in embodiment 1, and its difference is:

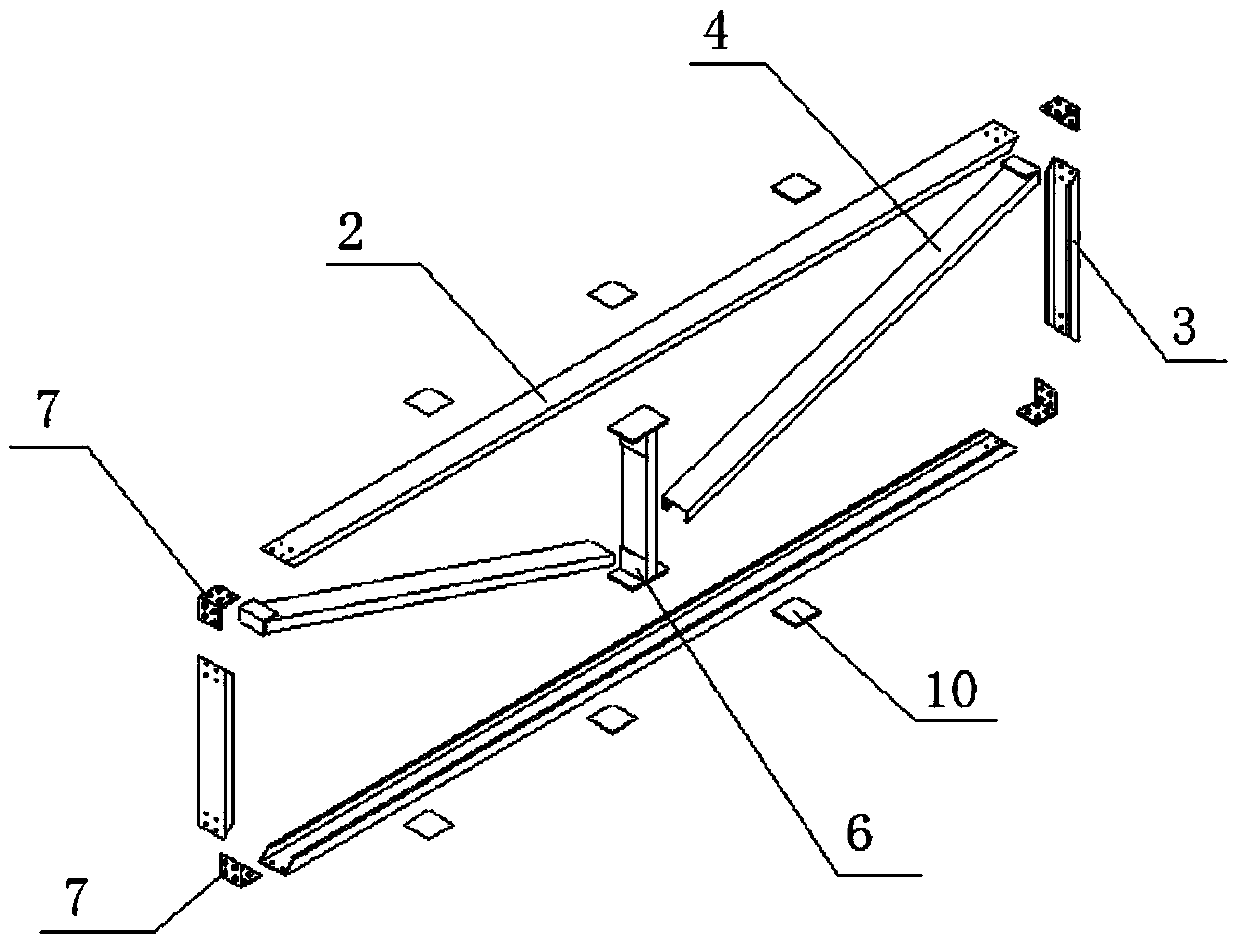

[0070] In this embodiment, the main ribs 2, auxiliary ribs 3, and reinforcing ribs 4 are like Figure 4 As shown, the reinforcing rib 4 is a tensile member, the auxiliary rib 3 is four parallel auxiliary ribs, and divides the upper and lower main ribs 2 into three parts, each part has a reinforcing rib 4, and two adjacent reinforcing ribs 4 A "V" shape is formed, and the other two adjacent reinforcing ribs 4 are parallel.

[0071] In this embodiment, the main rib 2 and the auxiliary rib 3 of the wall panel steel skeleton adopt C-shaped steel. The reinforcement rib 4 of the wall panel steel skeleton adopts steel bars, such as Figure 5 shown. When steel bars are used, the steel bars can be directly welded to the gusset plate, or the two ends of the steel bar are tapped and buckled, and bolts are used to fasten and straighten the steel bars ...

Embodiment 3

[0073] A kind of novel prefabricated wallboard, this wallboard is basically the same as that in embodiment 1, and its difference is:

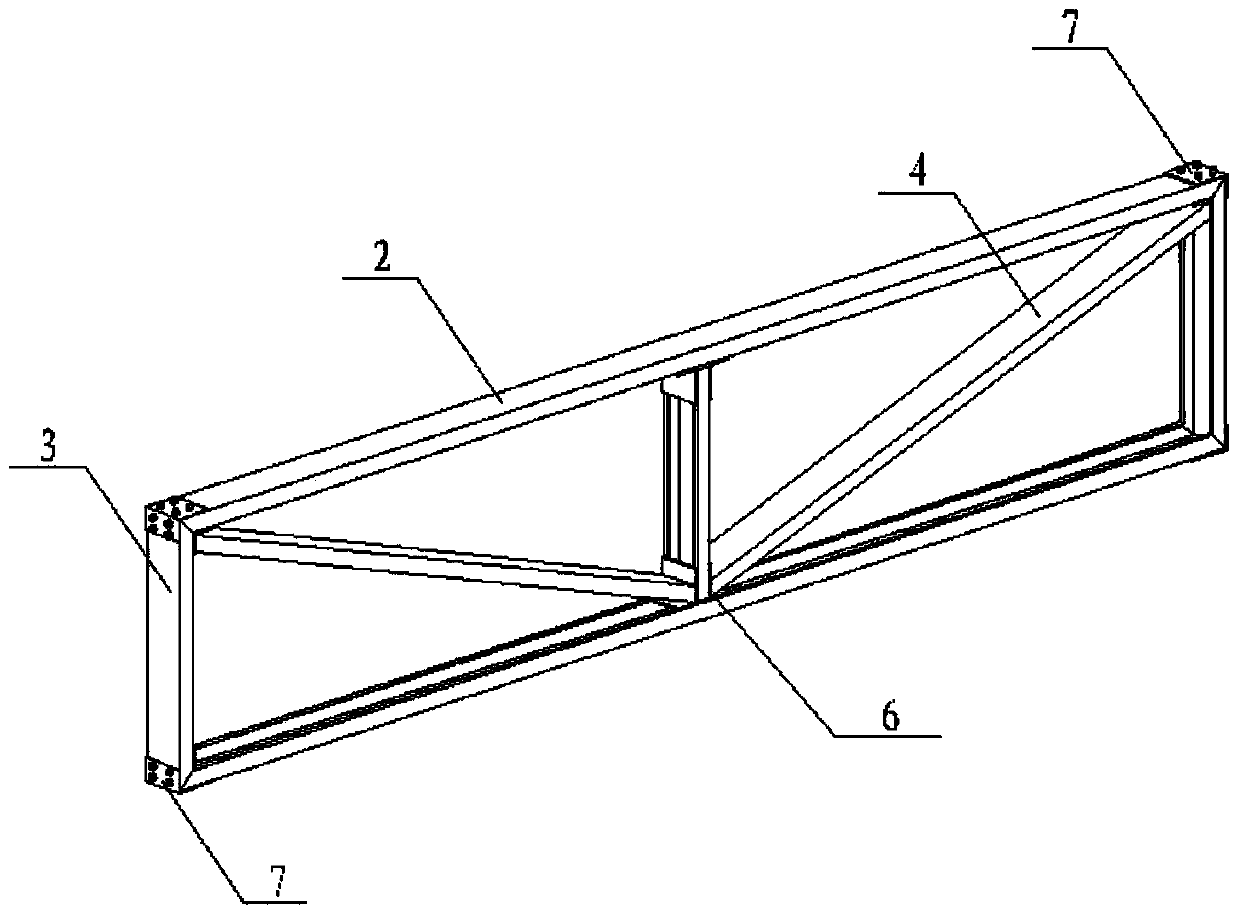

[0074] In this embodiment, the main ribs 2, auxiliary ribs 3, and reinforcing ribs 4 are shape connection, such as Image 6 As shown; the reinforcing rib 4 is a tensile member, the auxiliary rib 3 is five parallel auxiliary ribs, and divides the upper and lower main ribs 2 into four parts, each part has a reinforcing rib 4, and the middle two adjacent reinforcing ribs 4 into a "V" shape, and the reinforcing ribs 4 at both ends are respectively parallel to the adjacent reinforcing ribs 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com