Treatment process of antibiotic wastewater

A technology of antibiotic wastewater and treatment process, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that anaerobic process is difficult to exert normal effect and aerobic system cannot operate normally , can not meet the emission standards and requirements, and achieve the effect of simple facilities, low power consumption, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

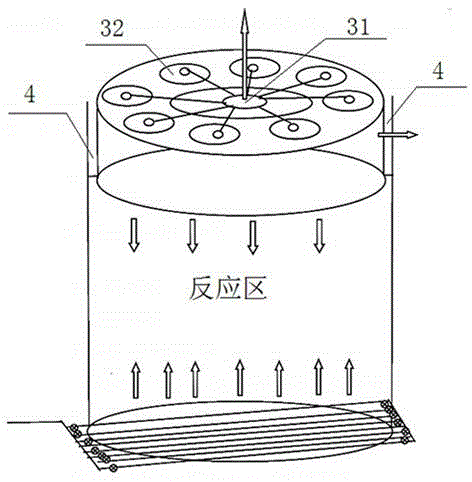

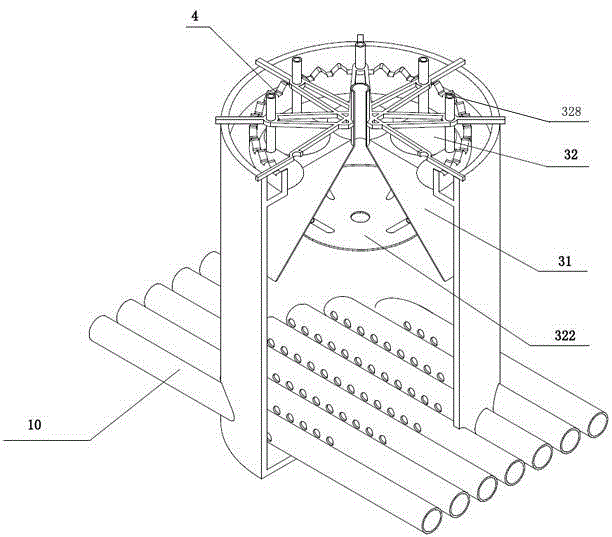

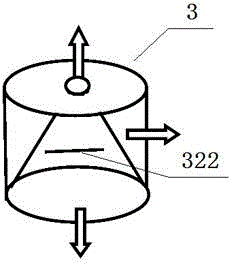

[0052] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0053] see figure 1 , is the flow chart of antibiotic wastewater treatment in the present invention. The treatment process of antibiotic waste water comprises the following steps:

[0054] A treatment process for antibiotic waste water, mainly comprising the following steps:

[0055] (s1) Raw water collection: collect all the sewage in the production area to the adjustment tank by gravity flow, stir and mix through the underwater stirring device, adjust the water quality and quantity, and ensure that the system can continuously and evenly enter water;

[0056](s2) Coagulation-sedimentation pretreatment: Sewage enters the coagulation-sedimentation reactor. In the coagulation-sedimentation reactor, the pH range is first adjusted to 6.5-7.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com