EGR rate correction system and method based on filling factor of internal combustion engine

A technology of internal combustion engine and factor, applied in the field of correction based on the system, EGR rate correction system based on internal combustion engine charge factor, EGR rate correction system, can solve the problems of wrong principle, difficulty in popularization, inaccurate calculation, etc., and increase durability Sexual risk, easy to promote, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

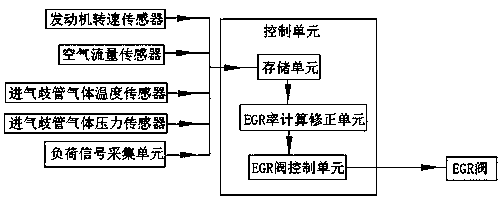

[0055] Such as figure 1 As shown, the present embodiment is an EGR rate correction system based on the charge factor of a turbocharged heavy-duty diesel engine, including a control unit, an engine speed sensor, an air flow sensor, an intake manifold gas pressure sensor, an intake manifold The pipe gas temperature sensor is connected with the load signal acquisition unit.

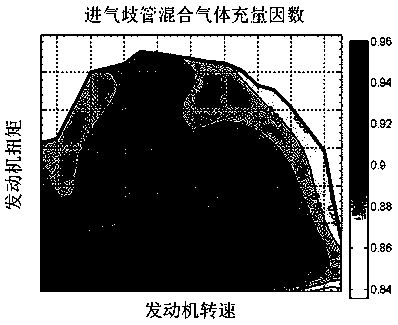

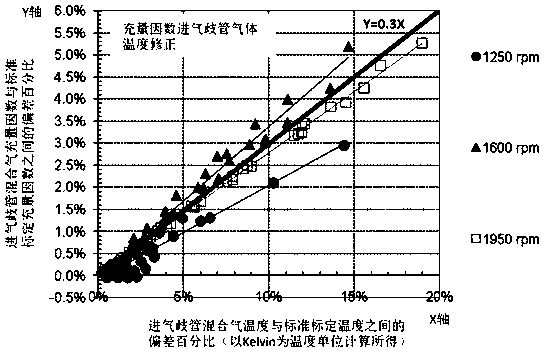

[0056] The control unit includes a storage unit, an EGR rate calculation and correction unit, and an EGR valve control unit, wherein: the storage unit stores the charge factor calibration map, and the rotational speed sensor, air flow sensor, intake manifold gas pressure sensor, intake manifold gas The data collected by the temperature sensor and the load signal collection unit and the calibration value or correction value of the target EGR rate. The load signal acquisition unit of this embodiment collects torque data.

[0057] The EGR valve control unit controls the opening of the EGR valve according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com