Electrochemical reactor for processing nitrogenous organic wastewater, and application and processing method thereof

An organic wastewater and electrochemical technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high cost and unsatisfactory denitrification effect, and achieve strong reducing ability, The selective oxidation ability of ammonia nitrogen is strong, and the effect of strong oxidation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

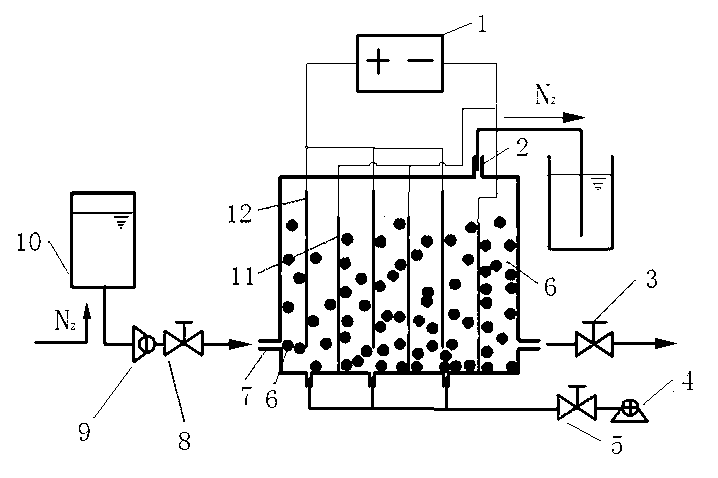

[0042] like figure 1 As shown, an electrochemical reactor for treating nitrogen-containing organic wastewater includes a reaction vessel, a power supply 1, an outlet pipe 2, an outlet pipe, an outlet pipe valve 3 and a water inlet system. The water inlet system consists of a water collector 10, a peristaltic pump 9. The water inlet valve 8 and the water inlet pipe 7 are sequentially connected in sequence; the water inlet pipe 7 is connected to the middle and lower part of the reaction vessel; the air outlet pipe 2 is connected to the top of the reaction vessel; the outlet pipe is connected to the middle and lower part of the reaction The water pipe valve 3 is controlled, and also includes packing 6, cathode plate 11 and anode plate 12, the filler is composed of activated carbon and magnet particles; the cathode plate 11 is connected to the negative pole of the power supply 1; the anode plate 12 is connected to the positive pole of the power supply 1; a cathode plate 11 and an...

Embodiment 2

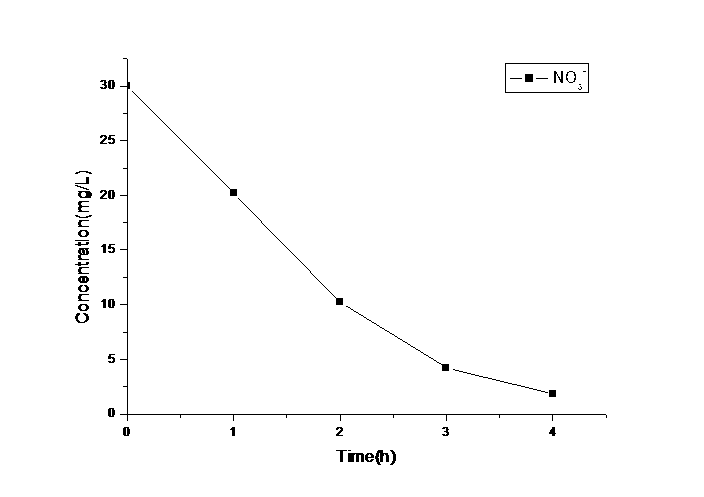

[0052] With embodiment 1, difference is: the activated carbon particle and the magnet particle ratio are 6:1 in the filler, the average particle diameter of activated carbon particle / magnet particle=120%, will contain nitrate ion concentration and be 30mg / L , the wastewater with a NaCl concentration of 0.5g / L enters the reaction vessel from the water inlet pipe 7 through the peristaltic pump 9, and adjusts the inflow flow so that the hydraulic retention time is 4h, and the applied current density is 20mA / cm 2 , Measure the concentration of nitrate nitrogen in the effluent every 1h. The processing effect is attached image 3 As shown, after 4 hours, the concentration of nitrate nitrogen in the effluent was 1.82mg / L, and the removal rate was 93.93%.

Embodiment 3

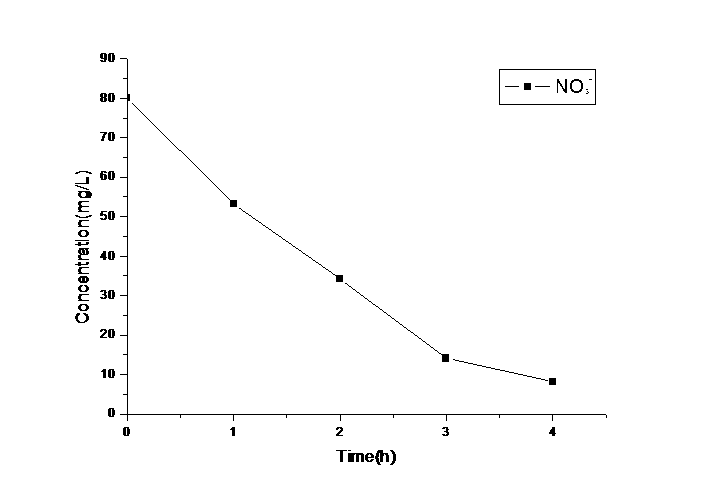

[0054] Same as Example 1, the difference is: the ratio of activated carbon particles and magnet particles in the filler is 2:1, the average particle diameter of activated carbon particles / average particle diameter of magnet particles=110%, the ammonia nitrogen concentration will be 60mg / L, NaCl Wastewater with a concentration of 0.5g / L enters the reaction vessel from the water inlet pipe 7 through the peristaltic pump 9, and adjusts the water flow rate so that the hydraulic retention time is 4h and the applied current density is 20mA / cm 2 , Measure the concentration of nitrate nitrogen in the effluent every 1h. The processing effect is attached Figure 4 As shown, after 4 hours, the concentration of ammonia nitrogen in the effluent was 7.12mg / L, and the removal rate was 88.13%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com