Active regeneration grading control method for particle trap

A particle trap and active regeneration technology, which is applied in the direction of machines/engines, engine components, combustion engines, etc., to achieve the effect of reducing exhaust back pressure and timely and effectively removing carbon deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

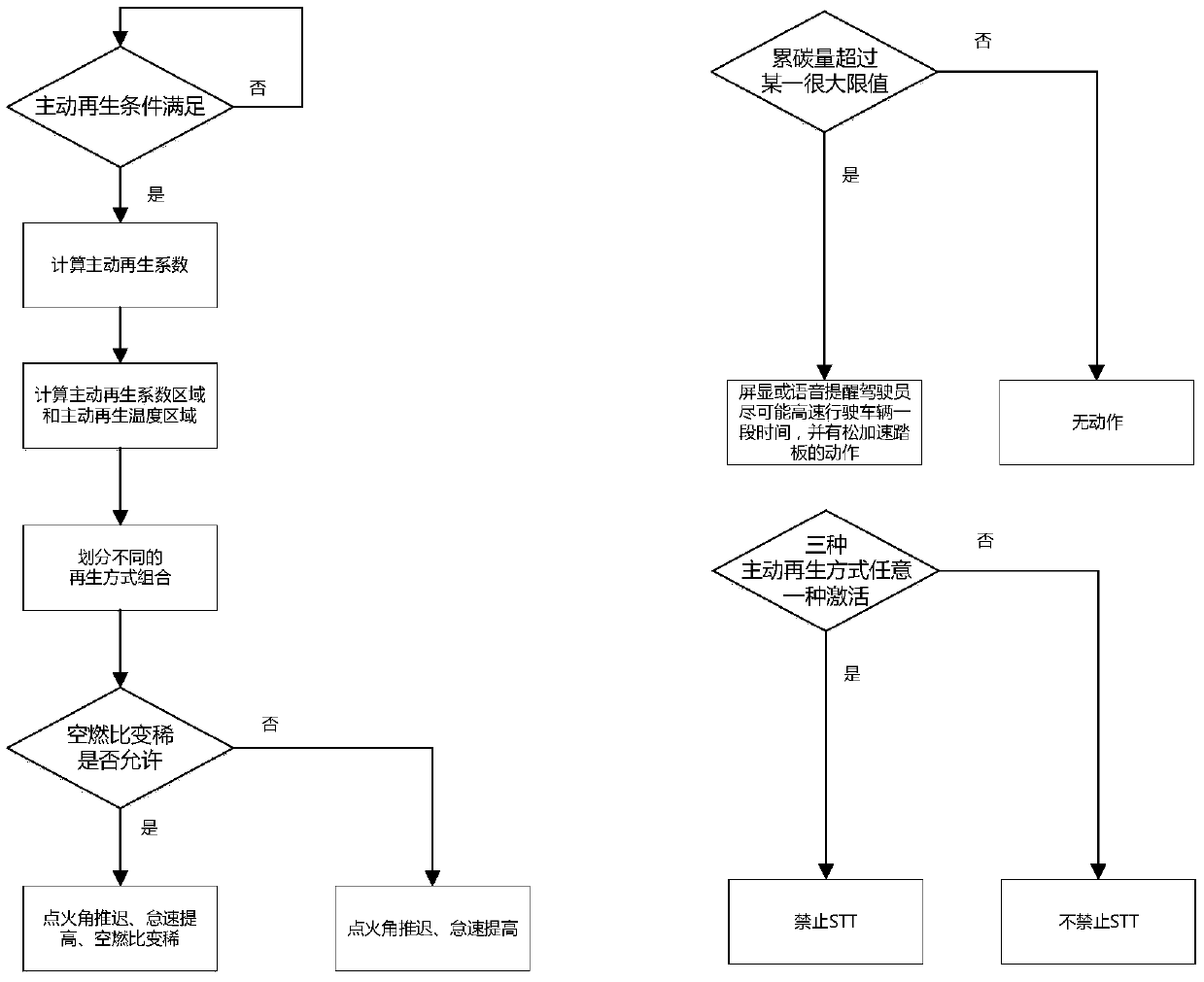

Embodiment Construction

[0029] The following specific implementation methods are used to explain the technical solutions of the claims of the present invention, so that those skilled in the art can understand the claims. The protection scope of the present invention is not limited to the following specific implementation structures. The protection scope of the present invention includes the technical solution of the claims of the present invention made by those skilled in the art and is different from the following specific embodiments.

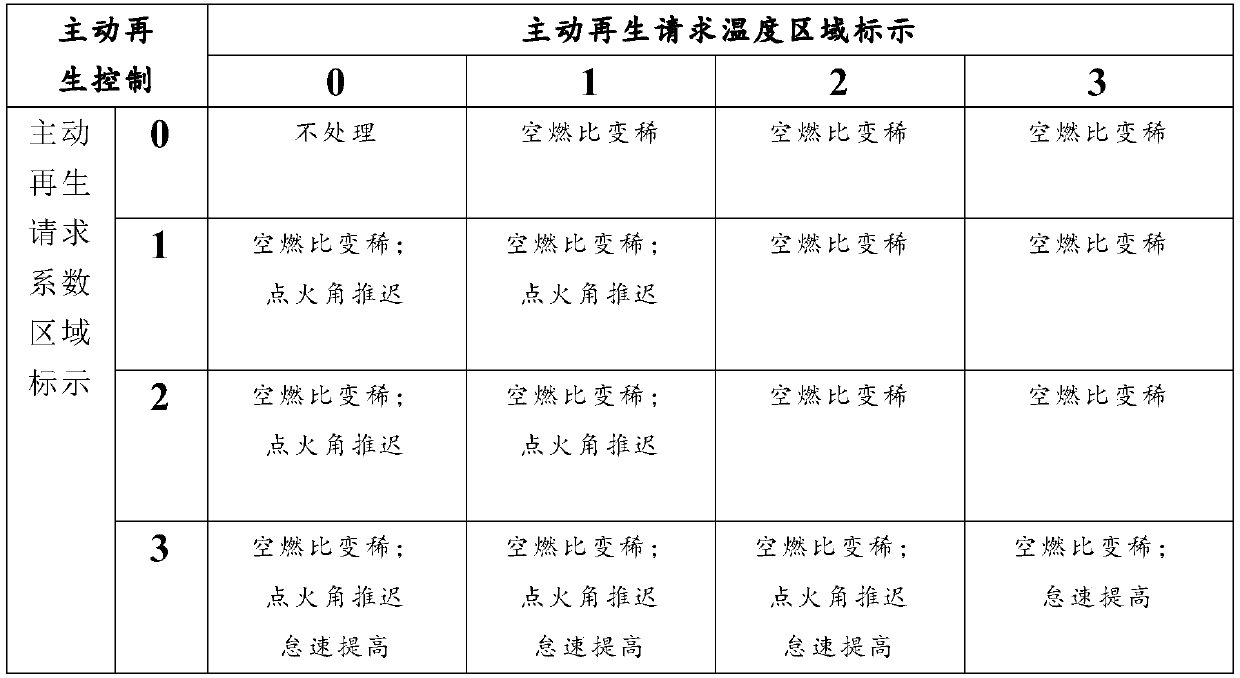

[0030] In the process of active regeneration, when the engine running state refers to the normal operation of the engine, retarding the ignition angle is to delay the normal ignition angle. For example, when the active regeneration request coefficient area is marked as 3 and the active regeneration request temperature area is marked as 0, the Reducing the ignition efficiency is 0.9 times of normal ignition efficiency; air-fuel ratio becomes leaner is to increase the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com