Electric fluid pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

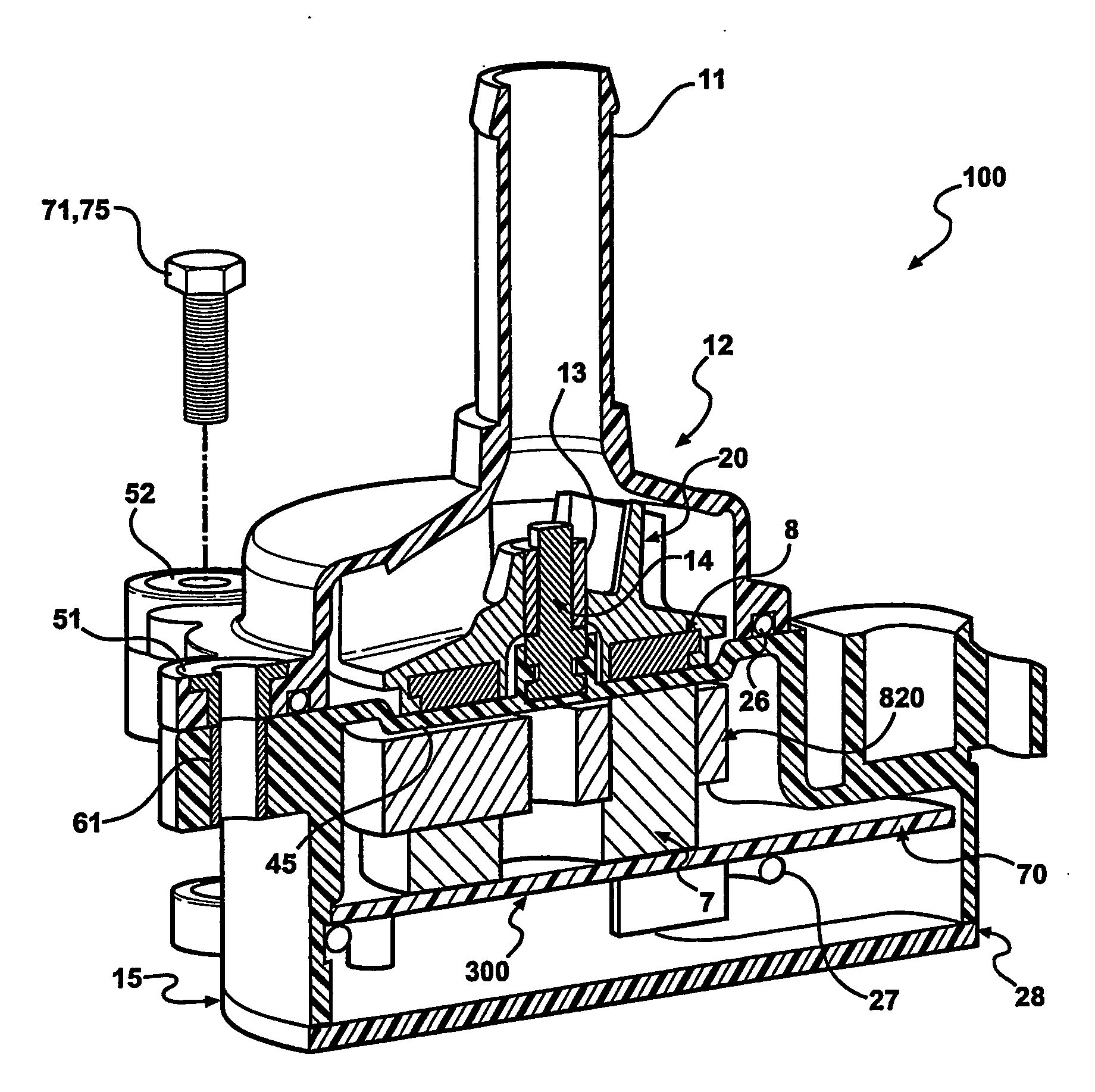

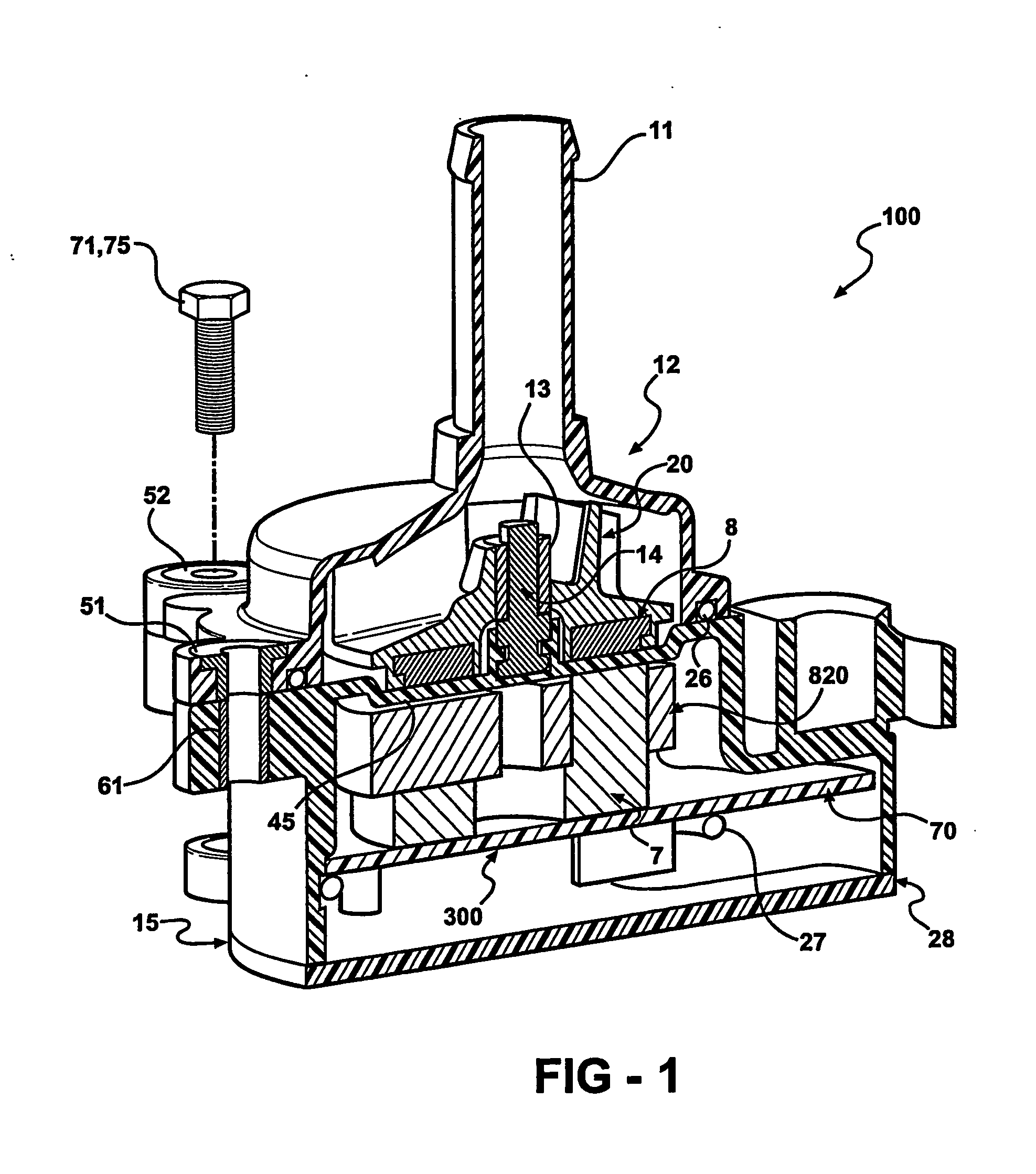

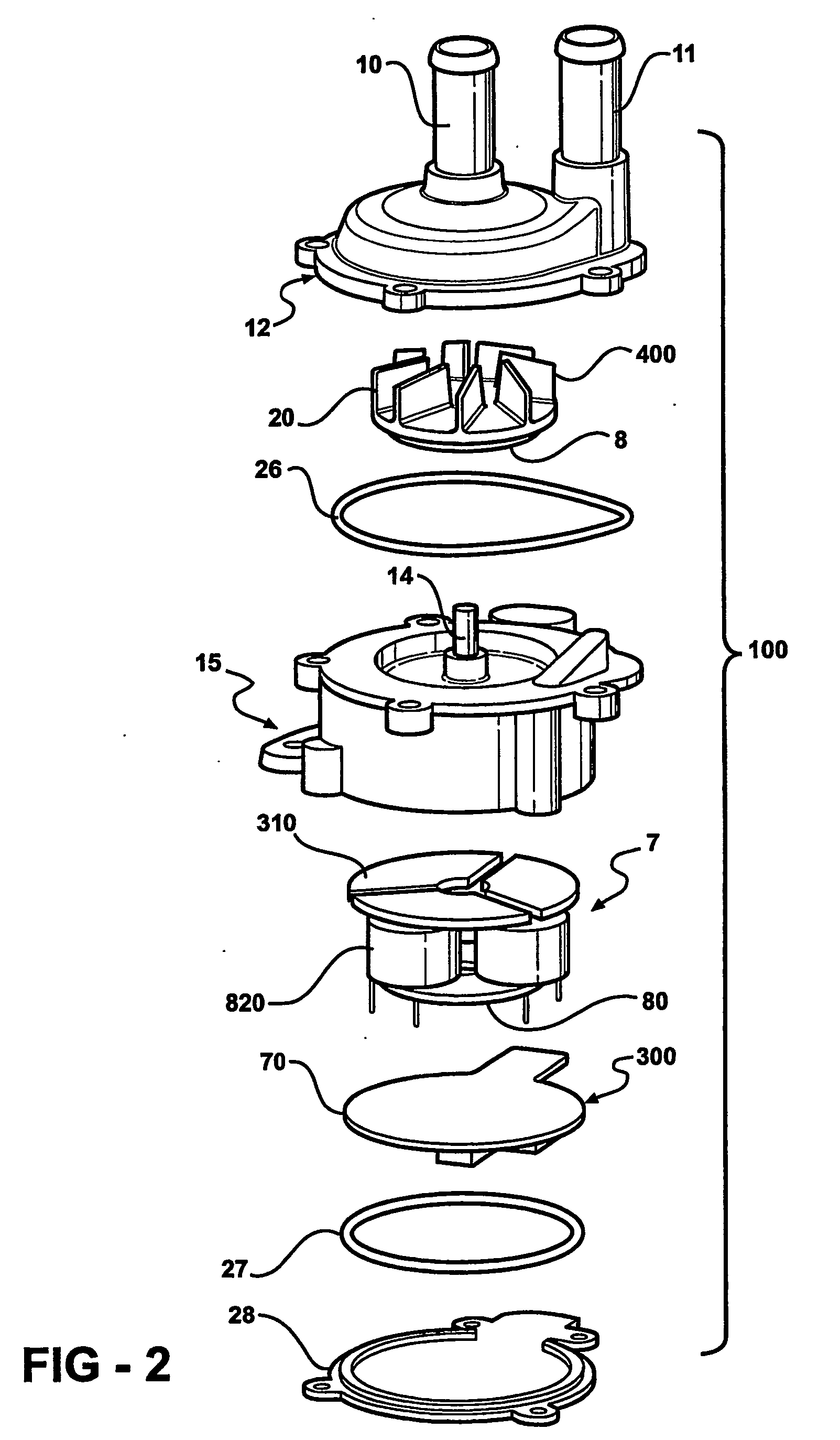

[0040] Referring to FIGS. 1-8, a pump assembly 100 is shown including an upper housing 12 with a fluid inlet 10 and outlet 11 and a lower housing 15. The upper 12 and lower 15 housing are preferably molded of polymeric material to provide good thermal characteristics and allow heat to dissipate into fluid within the housing. An impeller 20, preferably formed from injection-molded plastic, is seated within the interior volume of the upper housing 12. The impeller 20 is integrally formed with a permanent magnet and “back iron” assembly 8, which also serves as the rotor of a DC motor, to be described shortly. In one embodiment, the plastic impeller 20 encapsulates the magnet and “back iron” assembly 8 due to an overmolding or insert molding operation. Both the impeller 20 and rotor 8 include a central opening to accommodate both a bushing 13 and low friction shaft or spindle 14. The impeller 20 rotates around the shaft 14 that is fixed to the lower housing 15. The impeller / magnet assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com