Phosphorus-carbon composite material and preparation method and application thereof

A technology of carbon composite materials and composite materials, which is applied in the field of preparation of phosphorus-carbon composite materials, can solve problems such as poor cycle stability, low capacity, and low first-cycle Coulombic efficiency, and achieve excellent contact, relieve volume expansion, and excellent cycle stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

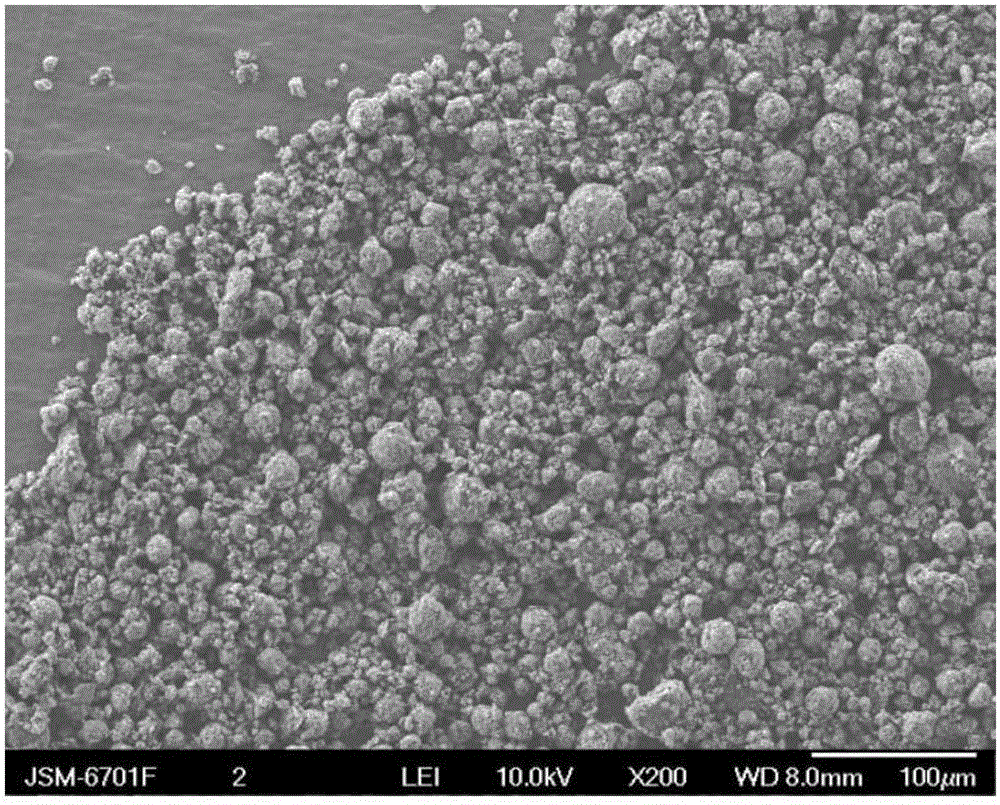

[0022] Mill micron red phosphorus with an average particle size of 5 μm, sodium alginate, and polyvinylpyrrolidone in an argon-protected ball mill for 24 hours. The frequency of the ball mill is 40 Hz. It is 10:1:1. Disperse graphite flakes and carbon nanotubes in an aqueous solution. The mass ratio of micron red phosphorus to graphite flakes and carbon nanotubes is 5:3.5:0.5. Add the dispersed graphite flake suspension into a ball mill tank and mill for 3 hours. The frequency is 25Hz. The obtained slurry is shaped by an open spray dryer. The atomizer of the spray dryer is a two-fluid atomizer, the gas used is air, the inlet temperature is 160°C, the outlet temperature is 100°C, and the airflow The temperature was 6 L / min, the feed rate was 25 r / min, and the obtained phosphorus-carbon composite material was dried at 180° C. in an argon atmosphere for 2 hours, and the temperature increase rate was 10° C. / min.

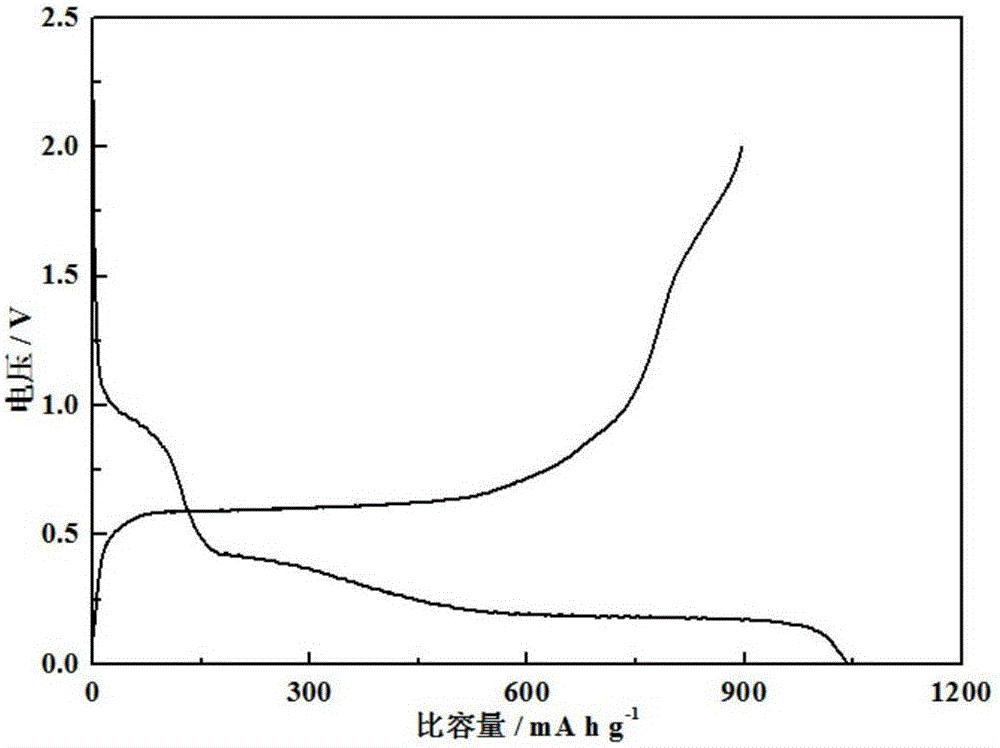

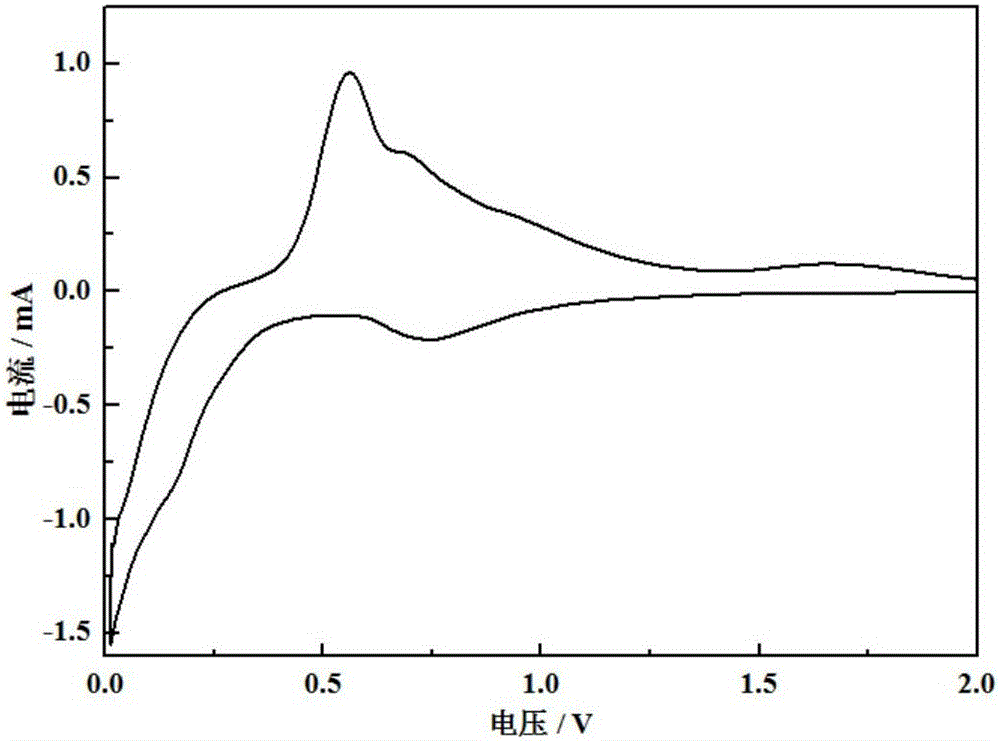

[0023] The phosphorus-carbon negative electrode material prepared...

Embodiment 2

[0026] Mill micron red phosphorus with an average particle size of 5 μm, sodium alginate, and polyvinylpyrrolidone in an argon-protected ball mill for 24 hours. The frequency of the ball mill is 40 Hz. It is 10:0.5:0.5. Disperse graphite flakes and carbon nanotubes in an aqueous solution. The mass ratio of micron red phosphorus to graphite flakes and carbon nanotubes is 5:4:0.5. Add the dispersed graphite flake suspension into a ball mill tank and mill for 3 hours. The frequency is 25Hz. The obtained slurry is shaped by an open spray dryer. The atomizer of the spray dryer is a two-fluid atomizer, the gas used is air, the inlet temperature is 160°C, the outlet temperature is 100°C, and the airflow The temperature was 6 L / min, the feed rate was 25 r / min, and the obtained phosphorus-carbon composite material was dried at 180° C. in an argon atmosphere for 2 hours, and the temperature increase rate was 10° C. / min.

[0027] The test method is the same as in Example 1, and the bat...

Embodiment 3

[0029] Mill micron red phosphorus with an average particle size of 5 μm, sodium alginate, and polyvinylpyrrolidone in an argon-protected ball mill for 24 hours. The frequency of the ball mill is 40 Hz. It is 10:1.5:1.5. Disperse graphite flakes and carbon nanotubes in an aqueous solution. The mass ratio of micron red phosphorus to graphite flakes and carbon nanotubes is 5:3:0.5. Add the dispersed graphite flake suspension into a ball mill tank and mill for 3 hours. The frequency is 25Hz. The obtained slurry is shaped by an open spray dryer. The atomizer of the spray dryer is a two-fluid atomizer, the gas used is air, the inlet temperature is 160°C, the outlet temperature is 100°C, and the airflow The temperature was 6 L / min, the feed rate was 25 r / min, and the obtained phosphorus-carbon composite material was dried at 180° C. in an argon atmosphere for 2 hours, and the temperature increase rate was 10° C. / min.

[0030]The test method is the same as in Example 1, and the batt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com