Molybdenum disilicide composite coating and preparation method thereof

A composite coating and molybdenum disilicide technology, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problem of low bonding strength of alloy matrix, easy low-temperature pulverization, poor thermal shock resistance, etc. problem, to achieve long service life and good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

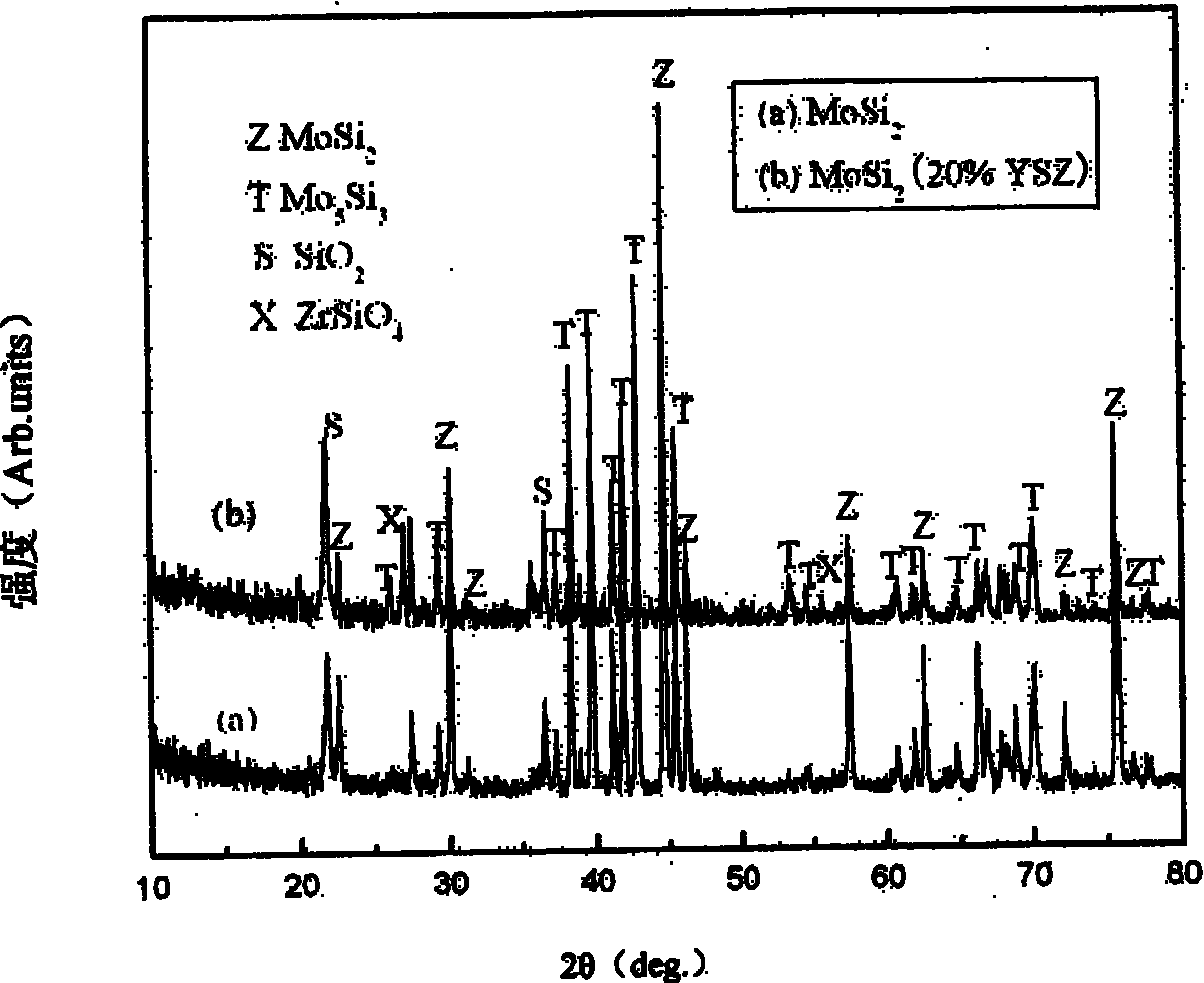

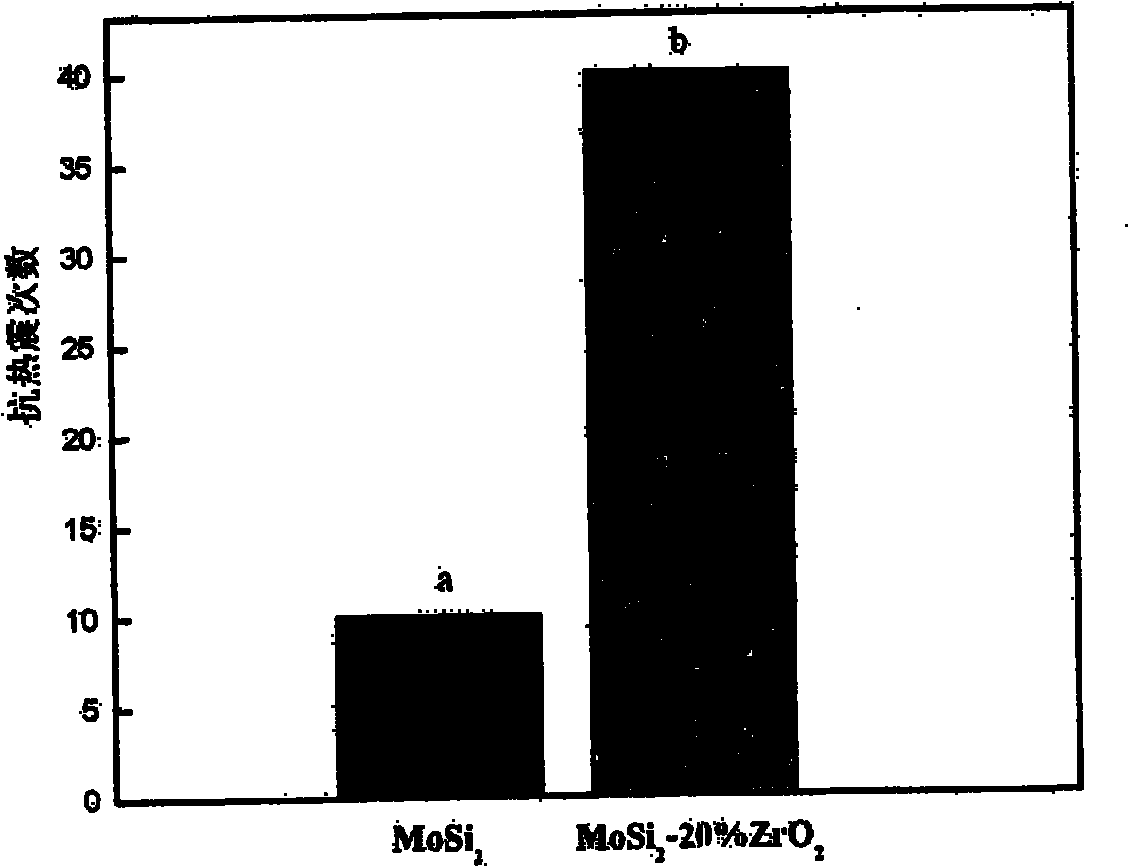

[0026] Select MoSi with a particle size distribution of 10-30 microns and a purity of 98.0% 2 Powder and ZrO with a particle size distribution of 10-60 microns and a purity of 98.0% 2 The powder is ball milled and mixed for 12 hours according to the volume ratio of 100:20, dried and then used for later use. Use NiCr metal powder with a particle size of 20-50 microns as the transition layer powder. Using vacuum plasma spraying technology, the process parameters listed in Table 3 are selected to prepare a NiCr transition layer on the nickel-based alloy, and then MoSi is prepared on it using the process parameters listed in Table 4. 2 -20%ZrO 2 Composite coating. Pure MoSi was prepared in the same way 2 coating for comparison. The prepared coating product was tested for the following oxidation resistance and thermal shock resistance, and it was found that:

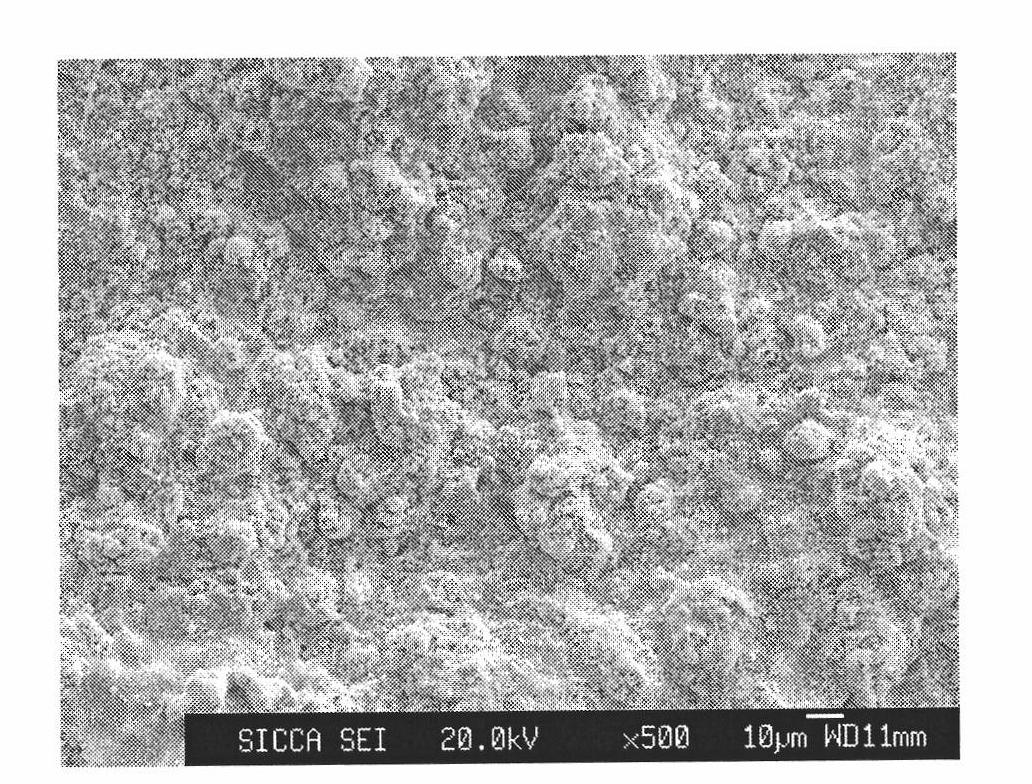

[0027] 1) After the coating was kept at 500°C for 16 hours, the surface morphology was observed ( image 3 ) shows M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com