All-solid-state polymer electrolyte, preparation method thereof, and all-solid-state lithium ion battery

An all-solid polymer and electrolyte technology, used in secondary batteries, circuits, electrical components, etc., can solve the problems of poor high voltage stability, low electrical conductivity, poor mechanical properties, etc., to prevent lithium metal powder and high electrical conductivity. , good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Specifically, the preparation method comprises the following steps:

[0049] Step S01. Dissolving at least one of aromatic diols and aromatic diamines, aromatic diacid chlorides, and polyethylene glycol in an anhydrous organic solvent, adding an acid-binding agent to it, and heating under an inert atmosphere to cause polymerization Reaction to obtain a polymer; step S02. dissolving the polymer obtained in step S01 in an organic solvent, and adding lithium salt thereto to obtain a mixed solution;

[0050] Step S03. Casting the mixed solution to form a membrane to obtain an all-solid polymer electrolyte.

[0051] Specifically, in the above step S01, the polymerization reaction needs to occur under anhydrous conditions, so the inorganic solvent can be dehydrated, such as adding a desiccant to the inorganic solvent, such as adding calcium chloride or molecular sieves, to absorb the inorganic solvent. moisture, and then mix the raw materials.

[0052] Preferably, the anhyd...

Embodiment 1

[0070] This embodiment 1 provides a preparation method of an all-solid polymer electrolyte.

[0071] The preparation method of the all-solid polymer electrolyte comprises the following steps:

[0072] (1). Dissolve 0.02mol 2-phenylterephthaloyl chloride, 0.0164mol 2-phenylhydroquinone and 0.0036mol polyethylene glycol (PEG, molecular weight 2kg / mol) in 100mL anhydrous tetrahydrofuran, Add 0.04mol triethylamine (Et 3 N or TEA or NEt 3 ), react at 60°C for 6h under nitrogen protection;

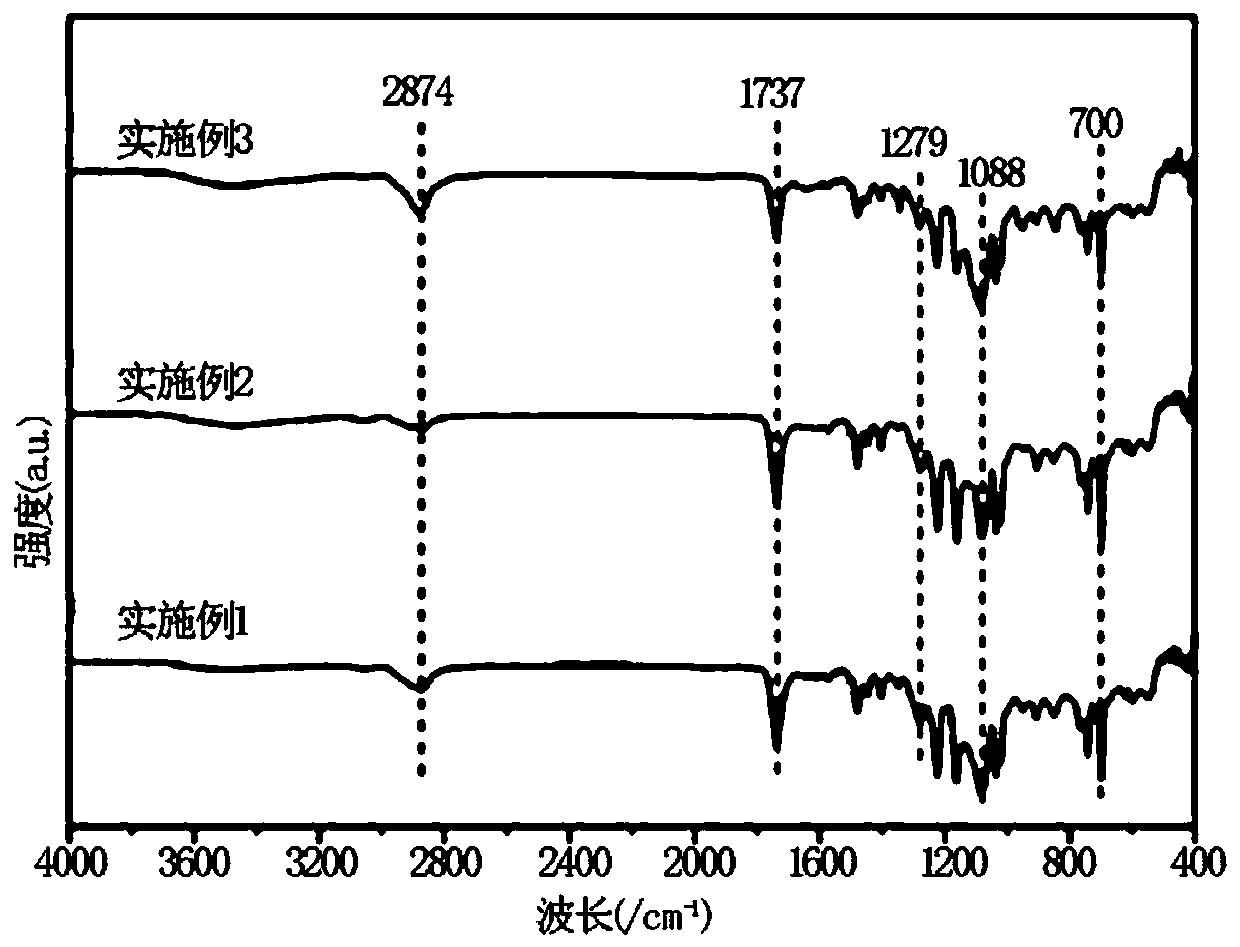

[0073] (2) the mixed solution that reaction finishes in the step (1) is cooled to room temperature, and filter treatment to filter out triethylamine hydrochloride, add 500mL ethanol and make product precipitation, decompression suction filtration, after ethanol washing product 3 times, in 60 Vacuum drying at ℃ for 24 hours to obtain a wholly aromatic polyester / PEG multi-block polymer. The molecular structure of the obtained multi-block polymer was characterized by infrared testing, specifical...

Embodiment 2

[0076] Example 2 provides a method for preparing an all-solid polymer electrolyte.

[0077] The preparation method of the all-solid polymer electrolyte comprises the following steps:

[0078] (1) Dissolve 0.02mol 2-phenylterephthaloyl chloride, 0.0187mol 2-phenylhydroquinone and 0.0013mol polyethylene glycol (PEG, molecular weight 6kg / mol) in 110mL anhydrous tetrahydrofuran, add 0.04mol triethylamine (Et 3 N or TEA or NEt 3 ), reacted at 60°C for 6h under nitrogen protection;

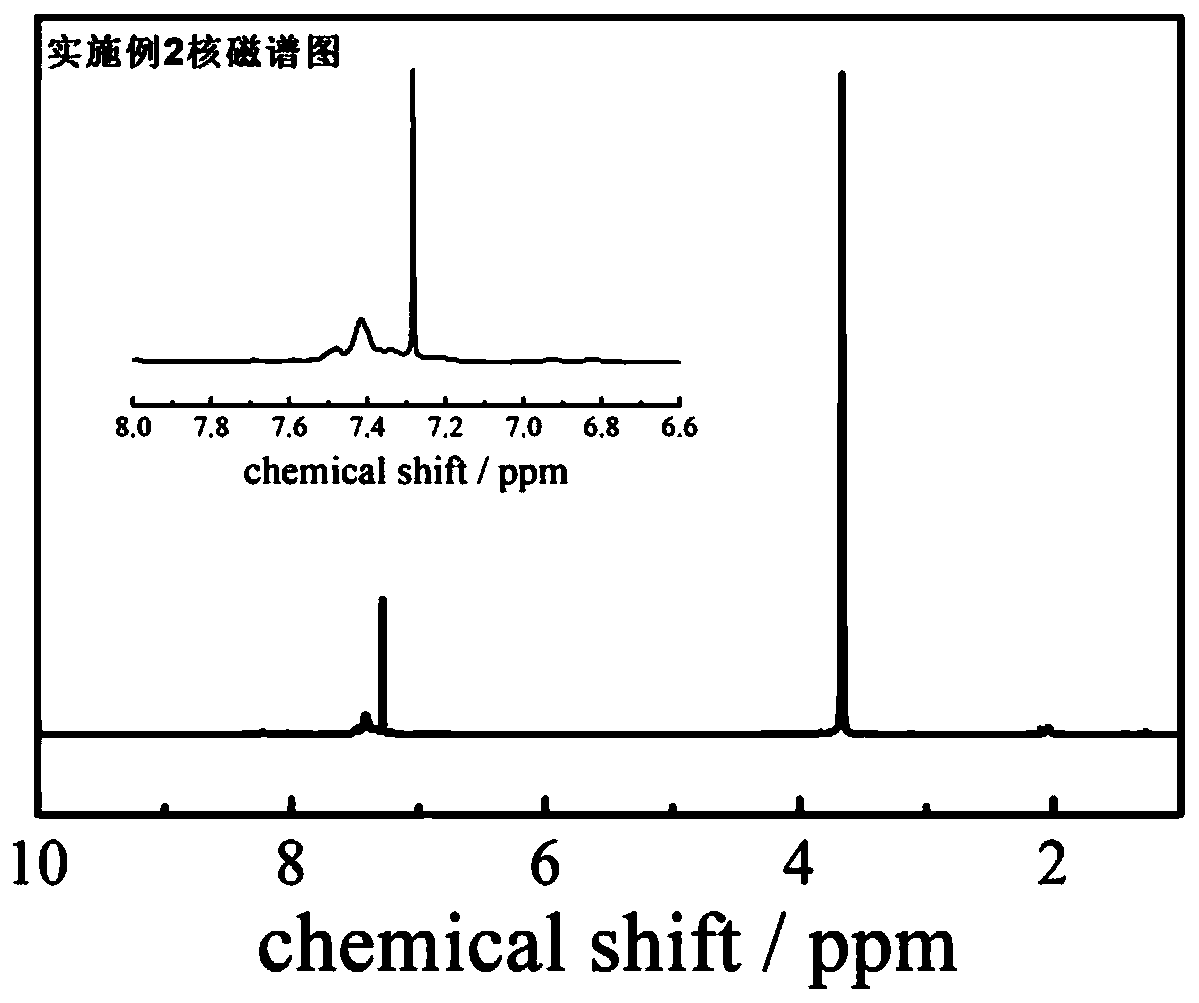

[0079](2) Cool the reaction mixed solution in step (1) to room temperature, filter off triethylamine hydrochloride, add 500mL of ethanol to precipitate the product, filter under reduced pressure, wash the product with ethanol for 3 times and vacuum at 60°C Dry for 24h to obtain a fully aromatic polyester / PEG multi-block polymer, and use infrared testing to characterize the molecular structure of the multi-block polymer obtained, specifically as figure 1 Shown; Simultaneously carry out its NMR charac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Electrochemical window | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com