Preparation method and application of hollow SnO2@C nanosphere in lithium ion battery

A lithium ion battery, hollow nano technology, applied in nano composite materials and their application fields, to achieve the effects of good dispersibility, large capacity and slowing down agglomeration and pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

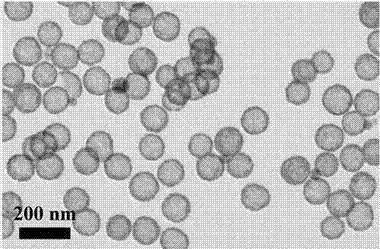

[0029] Add 60 mL of ethanol, 3 mL of ammonia water and 1 mL of water into a 100 mL flask successively, stir and mix evenly, then slowly add 2.3 mL of tetraethyl orthosilicate (TEOS) dropwise, 20 o C and stirred at constant temperature for 6 h. The resulting solution was centrifuged (7000 rpm, 8 min), washed several times with deionized water and absolute ethanol, and then washed at 50 o C for 10 h. Weigh 1.0 mg of the above oven-dried silica nanoparticles and disperse them in a mixed solution of 3 mL of water and 3 mL of ethanol, and then add 0.24 mL of 0.2 M urea (CH 4 N 2 O) and 0.45 mL 0.08 M sodium stannate (Na 2 SnO 3 ·H 2 O) was added to the above reaction solution, and after stirring for 0.5 h, the mixture was transferred to a 15 mL hydrothermal reaction kettle. 170 in oven o C for 1 h, naturally cooled to room temperature, centrifuged (7000 rpm, 8 min), and then washed several times with deionized water and absolute ethanol, the obtained solid was 50 o C drying...

Embodiment 2

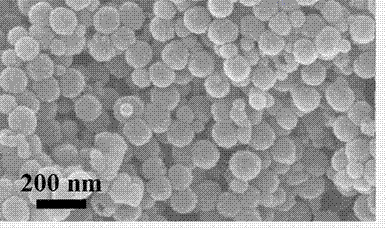

[0032] Add 80 mL of ethanol, 4 mL of ammonia water and 1.3 mL of water into a 100 mL flask successively, stir and mix evenly, then slowly add 3.0 mL of tetraethyl orthosilicate (TEOS) dropwise, 20 o C was stirred at constant temperature for 8 h. The resulting solution was centrifuged (7000 rpm, 10 min), washed several times with deionized water and absolute ethanol, and then washed at 60 o C for 10 h. Weigh 1.5 mg of the above dried silica nanoparticles and disperse them in a mixed solution of 3.5 mL of water and 3.5 mL of ethanol, and then add 0.3 mL of 0.2 M urea (CH 4 N 2 O) and 0.5 mL 0.08 M sodium stannate (Na 2 SnO 3 ·H 2 O) was added to the above reaction solution, and after stirring for 1 h, the mixture was transferred to a 15 mL hydrothermal reaction kettle. 170 in oven o C for 2 h, naturally cooled to room temperature, centrifuged (7000 rpm, 10 min), and then washed several times with deionized water and absolute ethanol, the obtained solid 70 o C dried for 8...

Embodiment 3

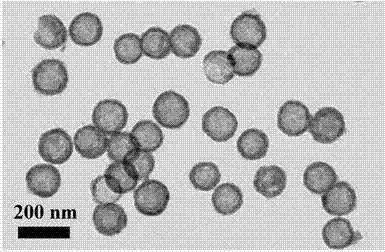

[0035] Add 70 mL of ethanol, 3.5 mL of ammonia water and 1.1 mL of water into a 100 mL flask successively, stir and mix evenly, then slowly add 2.0 mL of tetraethyl orthosilicate (TEOS) dropwise, 20 o C and stirred at constant temperature for 7 h. The resulting solution was centrifuged (7000 rpm, 9 min), washed several times with deionized water and absolute ethanol, and then washed at 70 o Dry at C for 8 h. Weigh 1.2 mg of the above dried silica nanoparticles and disperse them in a mixed solution of 3.2 mL of water and 3.2 mL of ethanol, and then add 0.22 mL of 0.2 M urea (CH 4 N 2 O) and 0.4 mL 0.08 M sodium stannate (Na 2 SnO 3 ·H 2 O) was added to the above reaction solution, and after stirring for 0.6 h, the mixture was transferred to a 15 mL hydrothermal reaction kettle. 170 in oven o C for 1.5 h, naturally cooled to room temperature, centrifuged (7000 rpm, 9 min), and then washed several times with deionized water and absolute ethanol, the obtained solid 60 o C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com