Graphene macroscopic body/tin oxide composite lithium ion battery anode material and process thereof

A graphene macro-body, ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as limited improvement, no buffer structure tin dioxide, etc., to improve cycle performance, facilitate transmission, and have The effect of facilitating the transmission of electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

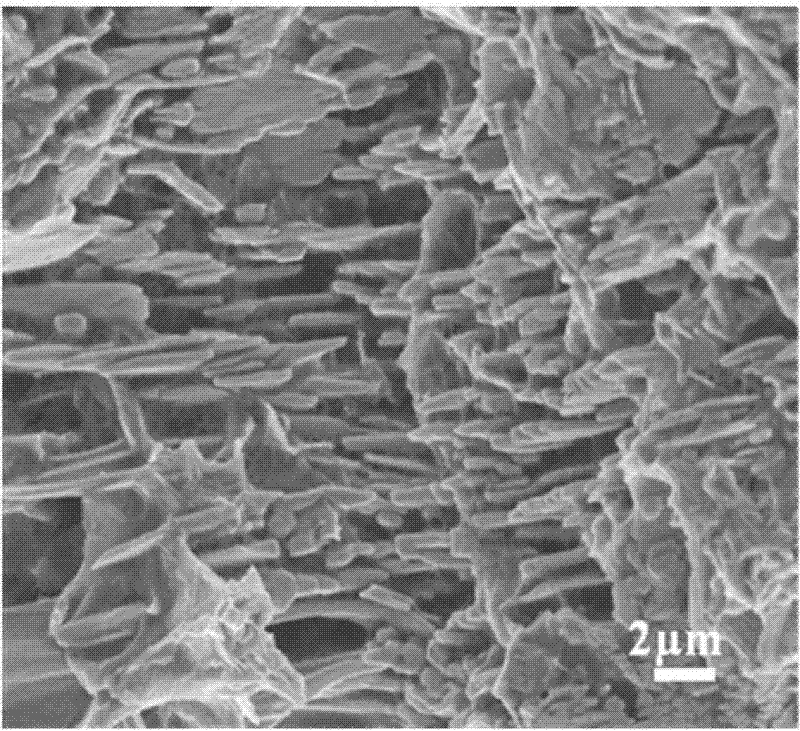

[0020] Take 18 mL of deionized water and add it to the beaker, add 2 mL of hydrochloric acid with a mass fraction of 37%, and then add 4.3 g of SnCl 2 2H 2 O was added to the beaker and stirred evenly to dissolve it all. Take 42 mg of the three-dimensional porous graphene macroscopic body and soak it in the solution. The measured pH value of the solution is 2-3, and the mouth of the beaker is sealed. After standing still for 24 hours, put the three-dimensional porous graphene macrobody adsorbed with tin salt into a vacuum oven at 70°C for 24 hours and dry it for 24 hours. After taking it out, put it into a tube furnace. Under the protection of argon, heat treatment is carried out, and the temperature is raised to 400°C at a heating rate of 5°C / min, then the temperature is kept at a constant temperature for 4 hours, and cooled to room temperature. The obtained material is the electrode material of the present invention. Coulombic efficiency reaches 99%.

[0021] like figure...

Embodiment 2

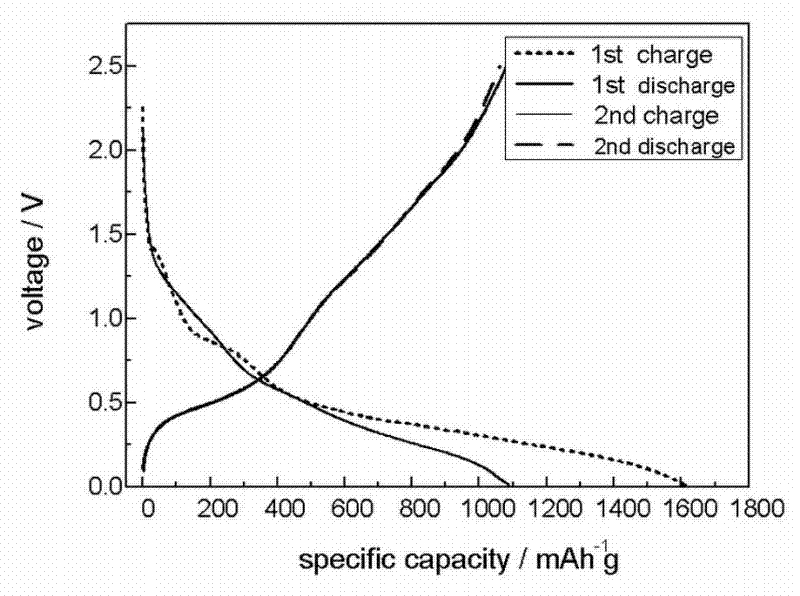

[0024] Take 20ml of deionized water and add it to the beaker, add 800mg of citric acid, then add 4.3g of SnCl 2 2H 2 O was added to the beaker and stirred evenly to dissolve it all. Take 42 mg of the three-dimensional porous graphene macroscopic body and soak it in the solution. The measured pH value of the solution is 2-3, and the mouth of the beaker is sealed. After standing still for 48 hours, put the macroscopic body adsorbed with tin salt into a 70°C vacuum drying oven for 24 hours, take it out, put it into a tube furnace, and pass it into argon gas after vacuuming, under the protection of argon gas Carry out heat treatment, raise the temperature to 500°C at a heating rate of 5°C / min, then keep the temperature for 4 hours, and cool to room temperature. The obtained material is the electrode material of the present invention, and its lithium storage reversible capacity reaches 1200mAh / g. 99%.

Embodiment 3

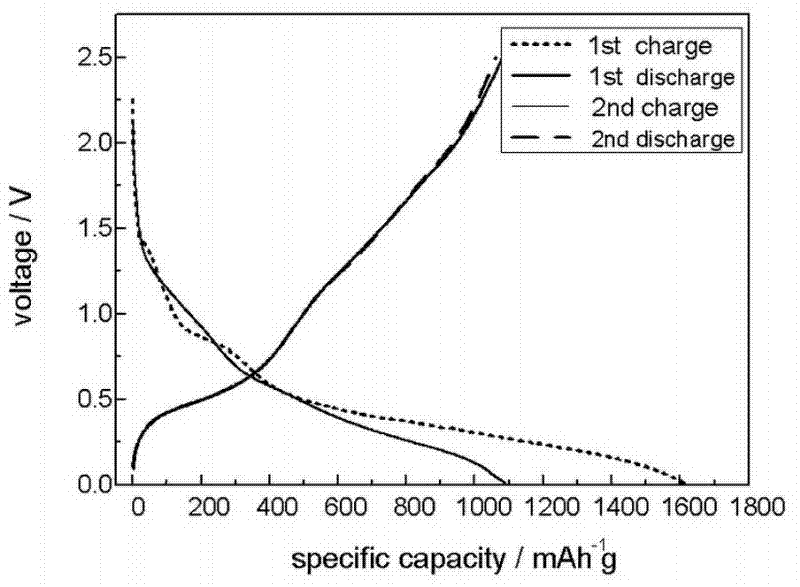

[0026] Get 18ml deionized water and join in the beaker, add the hydrochloric acid of 2ml mass fraction 37%, then 4.3g SnCl 2 2H 2 O was added to the beaker and stirred evenly to dissolve it all. Take 42 mg of the three-dimensional porous graphene macroscopic body and soak it in the solution. The measured pH value of the solution is 2-3, and the mouth of the beaker is sealed. After standing still for 24 hours, the obtained material was taken out from the solution, and freeze-dried at a temperature of -57°C for 24 hours. After taking it out, it was placed in a tube furnace, and argon or nitrogen was introduced after vacuuming. Heat treatment under protection, raise the temperature to 400°C at a heating rate of 5°C / min, then keep the temperature for 4 hours, and cool to room temperature. The obtained material is the electrode material of the present invention. The lithium storage reversible capacity reaches 1050mAh / g. Reached 99.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com