Method for preparing tin dioxide/graphene-compounded anode material of lithium ion battery

A graphene composite, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components and other directions, can solve problems affecting the electrochemical performance of lithium-ion battery negative electrode materials, etc., to achieve large-scale industrial production, raw material components are common and easy to obtain. , the effect of promoting the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 27g of choline chloride [purchased from Aladdin Reagent (Shanghai) Co., Ltd.] and 24g of ethylene glycol were stirred and mixed to obtain 51g of base solution (about 50mL). Dissolve 0.015g of graphene oxide powder into the base liquid to obtain a uniform mixed liquid. Then, 0.6 g of stannous chloride was added to the above mixture, and an ultrasonic oscillation reaction was performed for 5 hours in an ultrasonic cleaning machine with a power of 200 W and a frequency of 100 KHz. The obtained product was transferred to a centrifuge tube for centrifugation, and then the obtained precipitate was washed alternately with methanol and deionized water. After cleaning, it was dried in a vacuum oven at 60°C for 10 hours to obtain a black solid powder, which was the present product. Invented tin dioxide / graphene composite lithium-ion battery anode material.

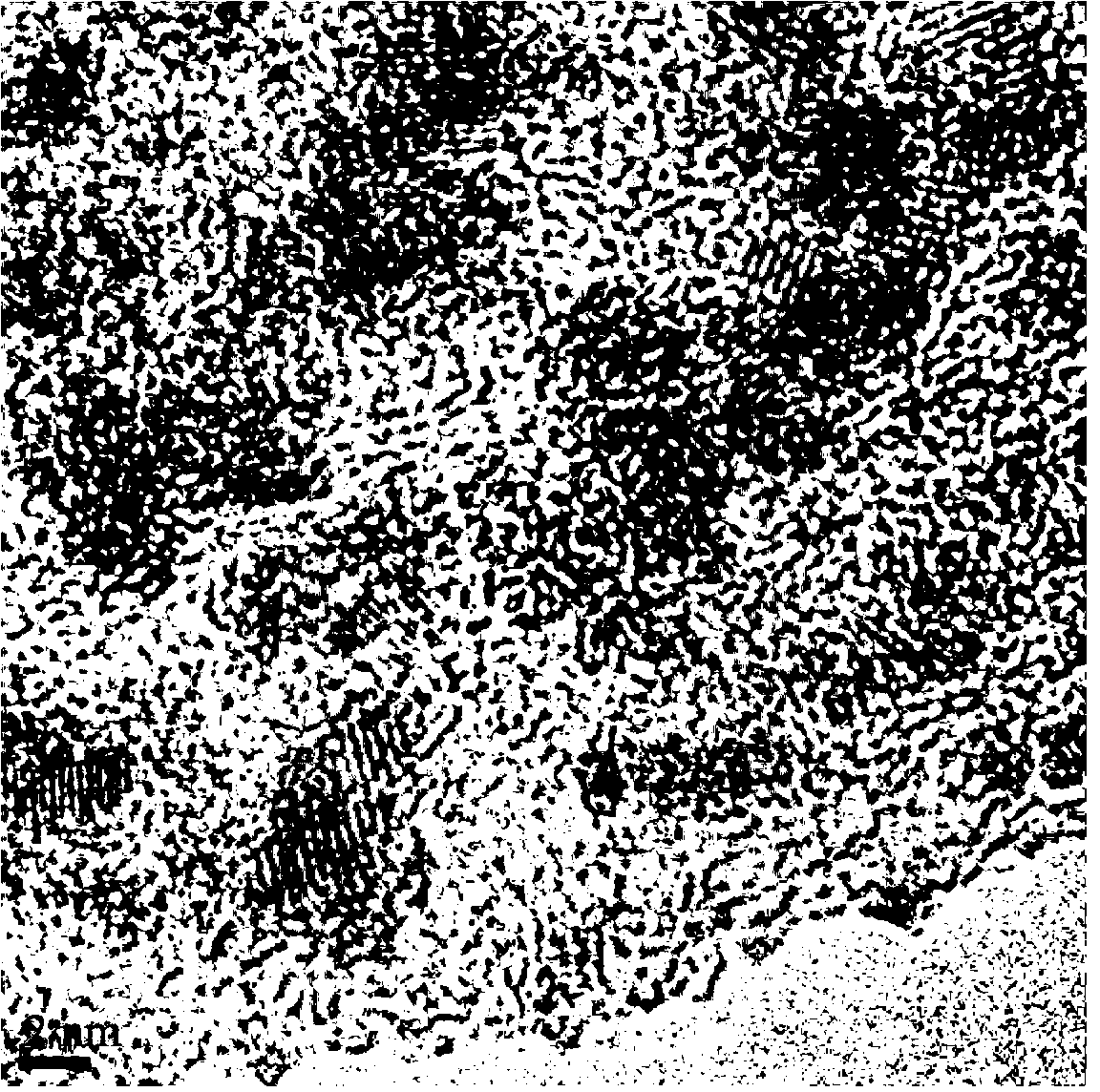

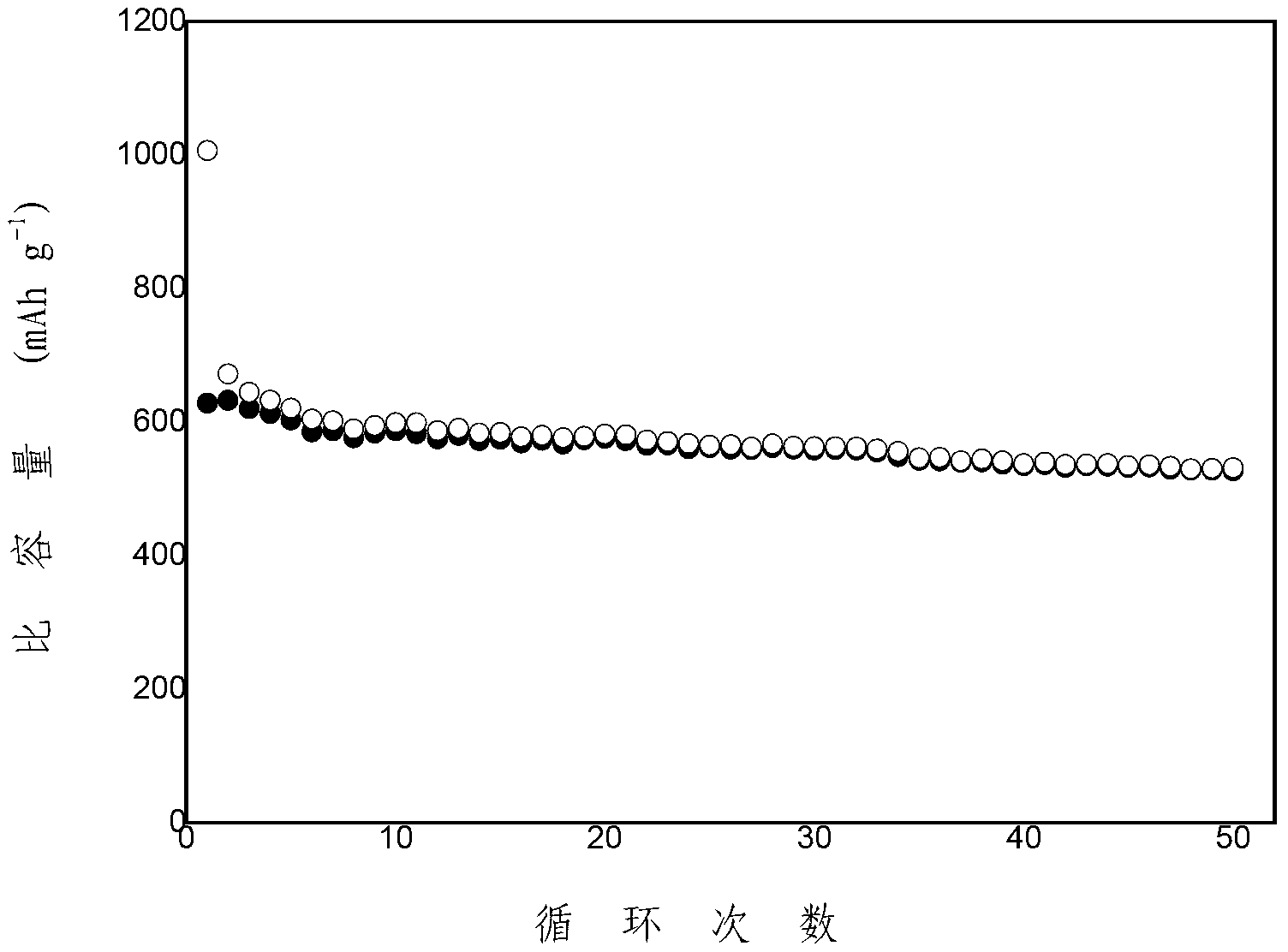

[0028] The transmission electron microscope photograph of the lithium-ion battery negative electrode material of the tin d...

Embodiment 2

[0030] 27g of choline chloride [purchased from Aladdin Reagent (Shanghai) Co., Ltd.] and 24g of ethylene glycol were stirred and mixed to obtain 51g of base solution (about 50mL). Dissolve 0.008g of graphene oxide powder into the base liquid to obtain a uniform mixed liquid. Then, 0.48 g of stannous chloride was added to the above mixture, and an ultrasonic oscillation reaction was performed for 3 hours in an ultrasonic cleaning machine with a power of 200 W and a frequency of 50 KHz. The obtained product was transferred to a centrifuge tube for centrifugation, and then the obtained precipitate was washed alternately with methanol and deionized water. After cleaning, it was dried in a vacuum oven at 60°C for 10 hours to obtain a black solid powder, which was the present product. Invented tin dioxide / graphene composite lithium-ion battery anode material.

[0031] According to the transmission electron microscope photos, it can be seen that the tin dioxide nanoparticles obtaine...

Embodiment 3

[0033] 27g of choline chloride [purchased from Aladdin Reagent (Shanghai) Co., Ltd.] and 24g of ethylene glycol were stirred and mixed to obtain 51g of base solution (about 50mL). Dissolve 0.010 g of graphene oxide powder into the base liquid to obtain a uniform mixed liquid. Then, 0.55 g of stannous chloride was added to the above mixture, and an ultrasonic oscillation reaction was performed for 4 hours in an ultrasonic cleaning machine with a power of 200 W and a frequency of 100 KHz. The obtained product was transferred to a centrifuge tube for centrifugation, and the obtained precipitate was washed alternately with methanol and deionized water. After cleaning, it was dried in a vacuum oven at 90°C for 5 hours to obtain a black solid powder, which was the present product. Invented tin dioxide / graphene composite lithium-ion battery anode material.

[0034] According to the transmission electron microscope photos, it can be seen that the tin dioxide nanoparticles obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com