Preparation method of silicon-based negative electrode active material, silicon-based negative electrode active material, lithium ion battery negative electrode material and lithium ion battery

A technology of active materials and silicon-based negative electrodes, which is applied in the preparation of silicon-based negative electrode active materials, silicon-based negative electrode active materials, and lithium-ion battery negative electrode materials. It can solve the problems that it is difficult to obtain silicon-based negative electrode active materials with greatly improved performance. , to avoid pulverization and electrode collapse, buffer volume change, improve electrical conductivity and mechanical toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

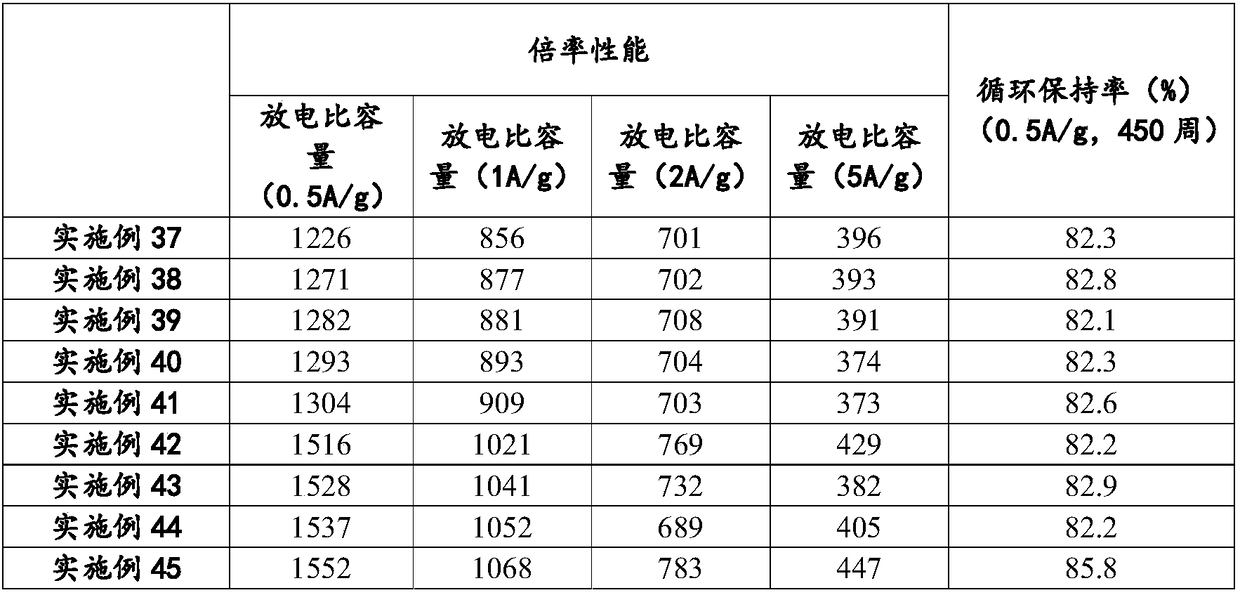

Examples

preparation example Construction

[0038] According to one aspect of the present invention, the present invention provides a preparation method of a silicon-based negative electrode active material, and the preparation method of the silicon-based negative electrode active material provided by the present invention includes the following steps:

[0039] (a) Coating SiO containing polymer protective agent on nano-silica powder 2 , to obtain a Si / SiO with nano-silicon as the core and silicon dioxide as the shell 2 composite material;

[0040] (b) in Si / SiO 2 Graphene oxide is coated on the composite material, and the graphene oxide is used as the shell layer, and the Si / SiO is coated 2 Composite Si / SiO 2 / GO composite material, where GO is the abbreviation of graphene oxide;

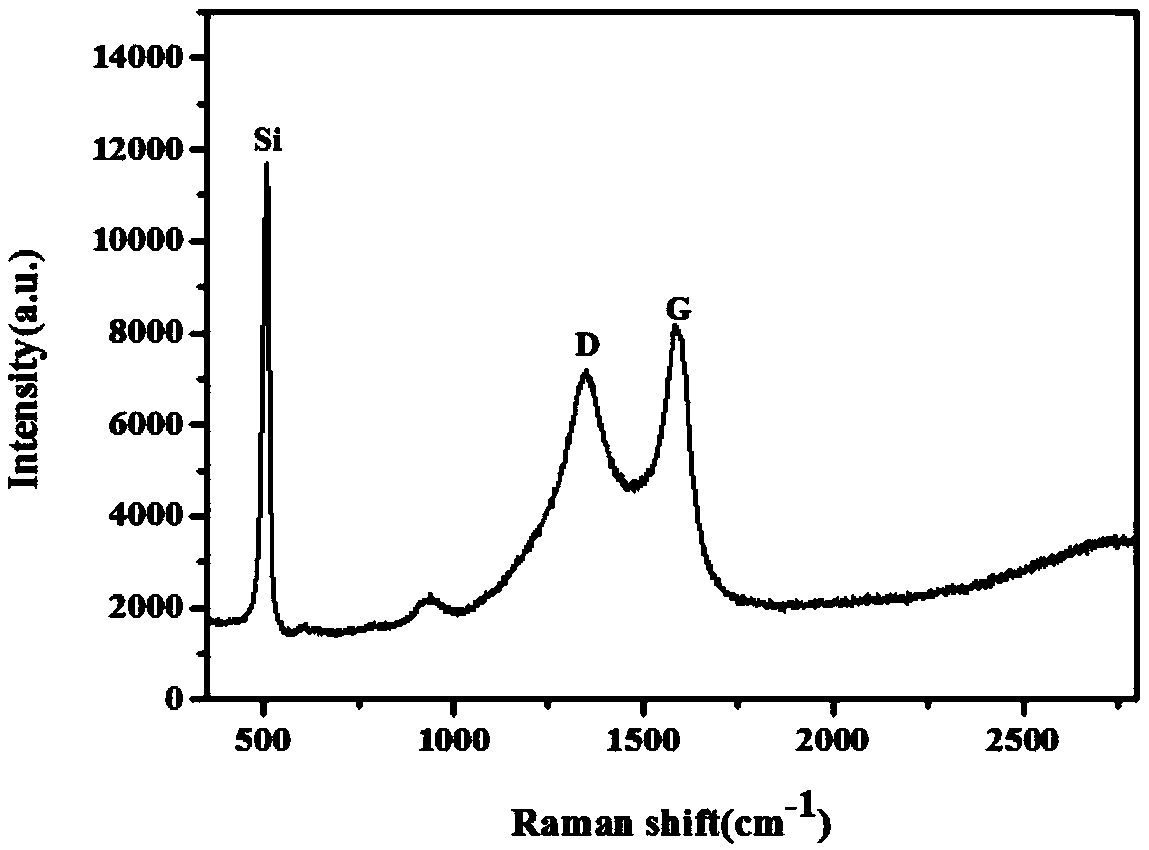

[0041] (c) Si / SiO 2 / GO composites were calcined to obtain Si / SiO 2 / Graphene composite material, Graphene is graphene, which is the product obtained after calcination of graphene oxide;

[0042] (d) Etching Si / SiO with strong acid so...

Embodiment 1

[0094] The present embodiment provides a method for preparing a silicon-based negative electrode active material, comprising the following steps:

[0095] (1) 10g nano-silicon powder (particle size ranging from 100-200nm) is stirred and dispersed into a mixed solution of ethanol and water to obtain a nano-silicon dispersion liquid, wherein in the mixed solution of ethanol and water, the volume ratio of ethanol and water is 1:1.

[0096] (2) Add 2g of PVP and 80mL of ammonia water to the nano-silicon dispersion, after mixing evenly, add 200ml of TEOS dropwise, then stir at room temperature for 1h, centrifuge, and dry to obtain Si with nano-silicon as the core and silica as the shell. / SiO 2 composite powder;

[0097] (3) Disperse 3 g of GO in ethanol with a concentration of 75% to obtain a GO dispersion;

[0098] (4) 97g Si / SiO 2 The composite powder was added to the GO dispersion, stirred for 12 h, and then spray-dried to obtain graphene oxide as the shell layer and coated...

Embodiment 2

[0102] This embodiment provides a method for preparing a silicon-based negative electrode active material. The difference between this embodiment and Embodiment 1 is that in step (b), the mass of PVP is 6 g and the TEOS is 120 mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com