Application of high-molecular coating in aluminium negative electrode, aluminium negative electrode, preparation method thereof and secondary battery

A polymer coating and polymer material technology, applied in the field of electrochemical energy storage devices, can solve the problems of unstable solid electrolyte membrane capacity attenuation, inability to effectively improve volume expansion, SEI membrane instability, etc., and achieve capacity retention High Coulombic efficiency, reduced irreversible capacity, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

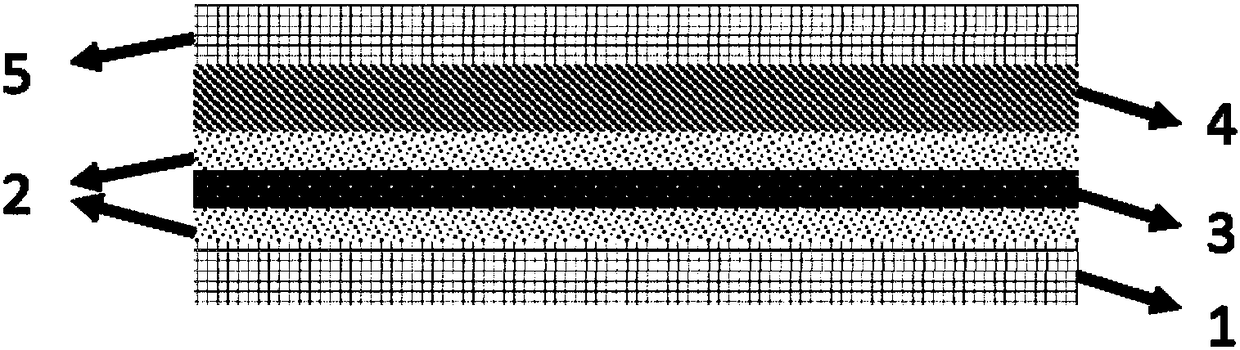

[0119] According to the third aspect of the present invention, there is provided a method for preparing the aluminum negative electrode, including the following steps:

[0120] Mix the polymer material, optional lithium ion conductor, optional conductive agent and optional surfactant to form a slurry, and coat it on the aluminum negative electrode; or,

[0121] The polymer material, the lithium ion conductor, the conductive agent and the surfactant are separately made into corresponding slurries, and then the corresponding slurries are respectively coated and dried to obtain an aluminum negative electrode.

[0122] In the preparation method of the aluminum negative electrode of the present invention, the coating materials are mixed to form a slurry and coated on the aluminum negative electrode, or the coating materials are separately prepared into a slurry, and then separately coated to obtain the slurry, the production process is simple and the cost is low.

[0123] As a preferred emb...

Embodiment 1

[0147] Dissolve 1g of polyvinyl alcohol in 10g of water, stir evenly to form a completely uniform solution, add an appropriate amount of phytic acid solution, and after stirring, add an appropriate amount of Al nanoparticle dispersion and stir for 2h to form a slurry. The slurry is coated with a coater to form a film on the surface of the aluminum foil, and then dried in a vacuum oven at 80°C for 8 hours to completely remove the solvent water. Cut the dried aluminum foil to obtain the aluminum negative electrode metal foil / current collector of the required size.

[0148] Use aluminum anode metal foil / current collector as anode, use LiPF 6 / EC:DEC (v:v=4:6) is the electrolyte, and the battery is assembled with lithium iron phosphate as the positive electrode.

Embodiment 2-20

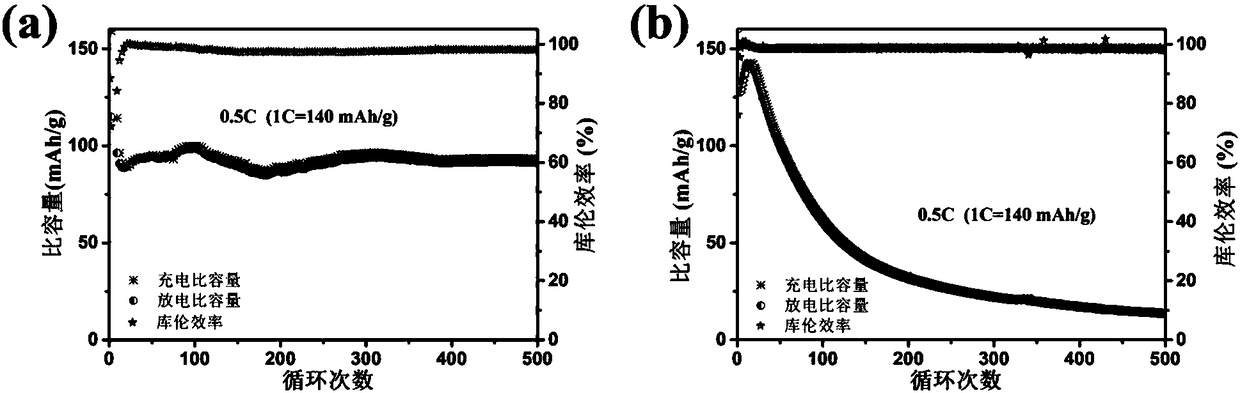

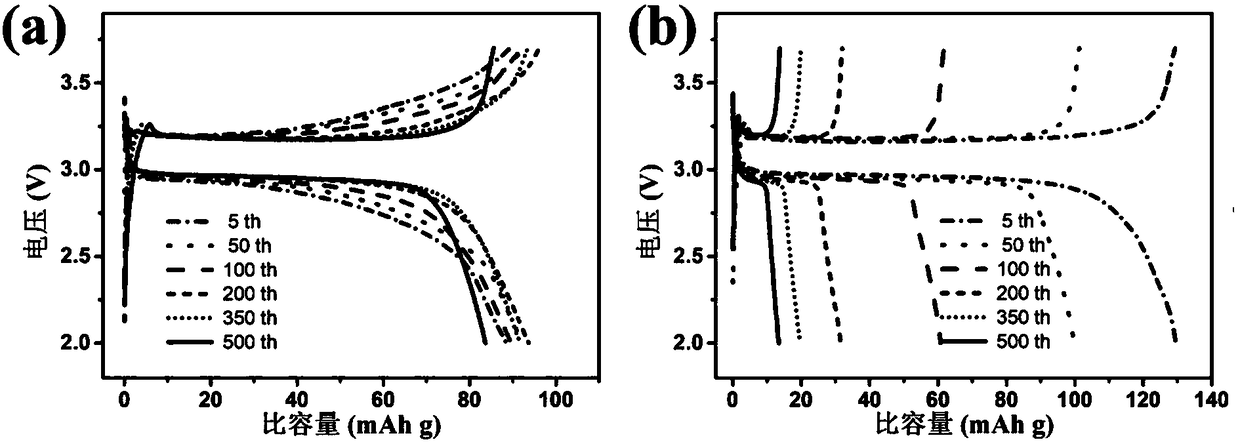

[0150] The difference between Example 2-20 and Example 1 is that the selected polymer materials are different, and the rest of the steps are the same. The performance test of the battery obtained in Example 2-20 is performed, and the performance of Example 1 is compared. The battery test includes the capacity retention rate and coulomb efficiency of 500 cycles, using conventional battery test methods. The specific test method is as follows:

[0151] Cyclic charge and discharge: Cyclic charge and discharge are performed on the CT2001C-001 blue battery cycle test system, charge and discharge at a rate of 0.5C (100mAh / g) to test the standard capacity of the electrode, the specific capacity of the material = current * time / sample quality, The coulombic efficiency of the material = the discharge capacity of the material / the charge capacity of the material. The charging and discharging conditions depend on the needs of the experiment. The cycle steps include: standing for 60s-constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com