Mg-Si-Sn series magnesium alloy and heat treatment process for deteriorate Chinese character shaped eutectic Mg2Si phase therein

A magnesium alloy, mg-si-sn technology, applied in the field of heat treatment technology, can solve the problems of insufficient heat resistance and poor comprehensive mechanical properties of Sn-enhanced magnesium alloys, so as to overcome the lack of heat resistance, improve production efficiency, and improve high temperature Effects of Tensile and Creep Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

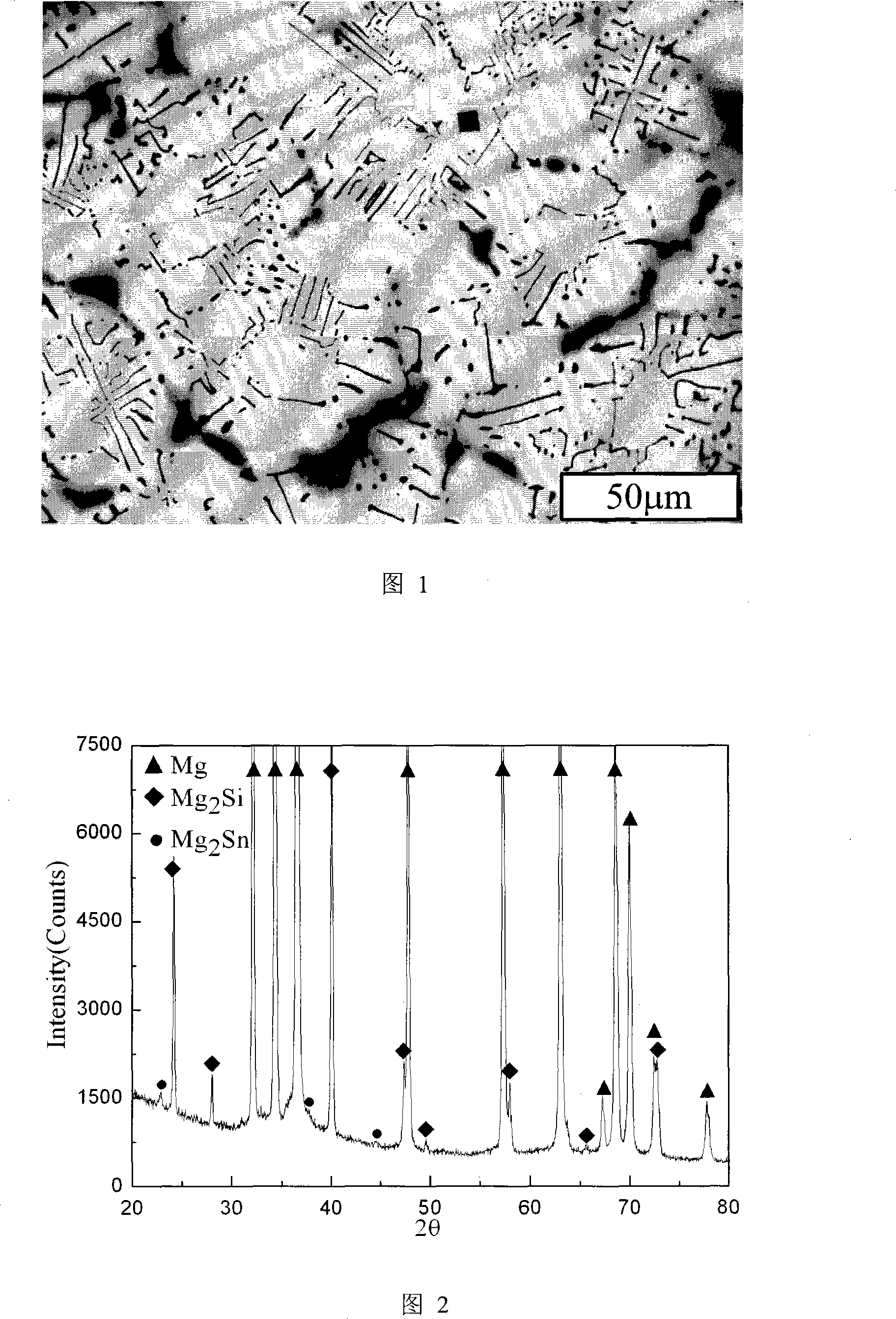

[0024] Using industrial pure magnesium ingot (purity 99.5%), industrial crystalline silicon powder (purity 99.4%, particle size 0.5 ~ 2mm) and pure tin ingot (purity 99.9%), according to the composition of Mg-3Si-3Sn alloy formulation alloy, in RJ- 2 Under the protection of flux, first melt the pure magnesium ingot in a resistance furnace, when the temperature rises to 780°C, add silicon powder and keep it warm for 1 hour, then add pure tin, keep it warm for 5 minutes, and then carry out mechanical stirring to make the alloying element silicon Homogenize with tin, let it stand for 10-15 minutes, and finally when the temperature drops to 720°C, remove the scum on the surface of the alloy liquid, pour it into a metal mold or sand mold for gravity casting. The metallographic structure observation and X-ray diffraction (XRD) analysis of the as-cast Mg-3Si-3Sn alloy obtained by the present invention are shown in Fig. 1 and Fig. 2 respectively. Combining Figure 1 and Figure 2, it ca...

Embodiment 2

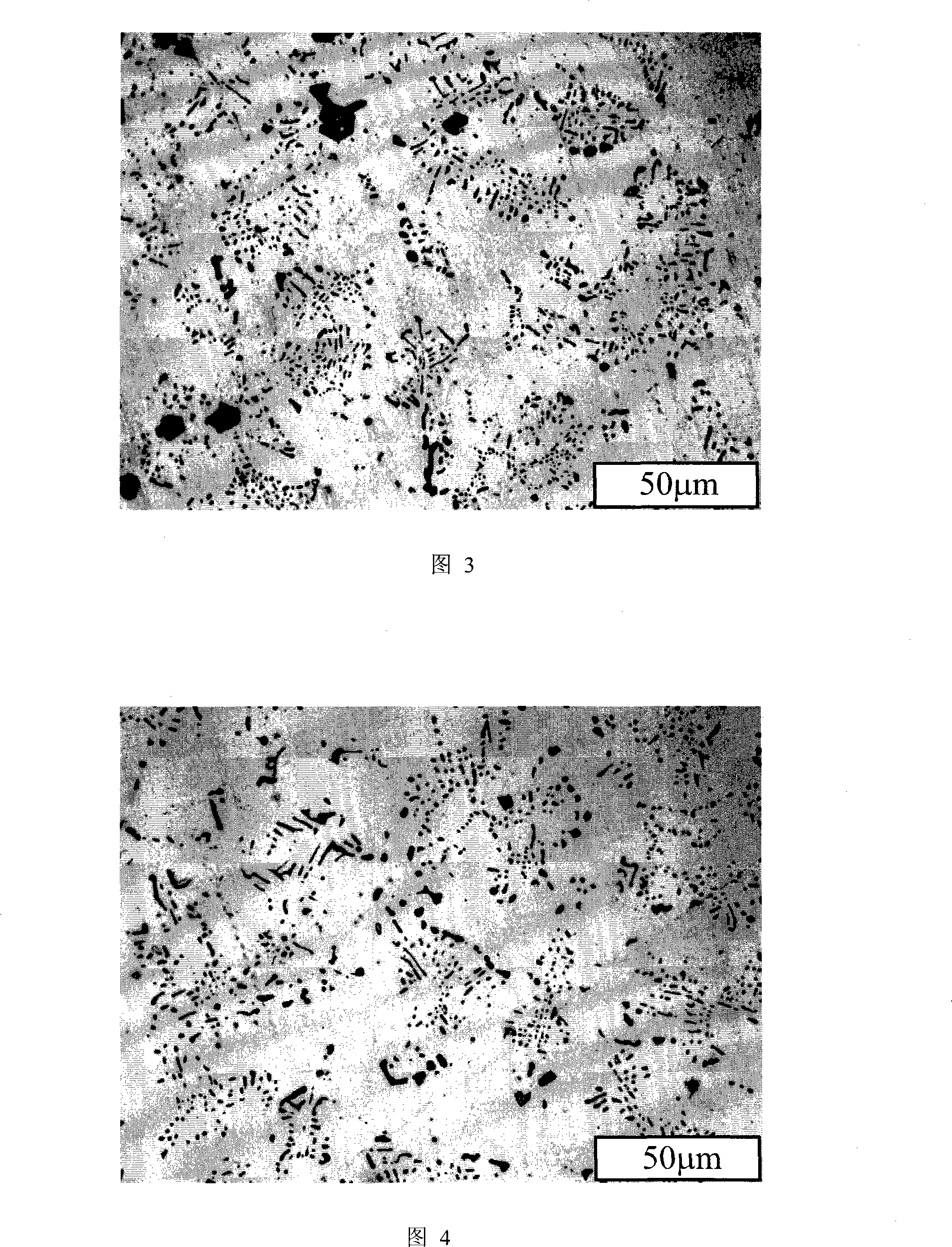

[0026] The Mg-3Si-3Sn magnesium alloy smelted according to the composition ratio is poured into a metal mold or a sand mold for gravity casting. Afterwards, the casting is kept in a box-type resistance furnace with a protective atmosphere, and then quickly taken out and put into water for quenching. The isothermal heat treatment temperature is 490 ° C, and the holding time is 4 hours. The metallographic structure of the alloy obtained by adopting the present invention is observed, and the result is shown in FIG. 3 . As can be seen from the figure, compared with the as-cast metallographic structure diagram (Fig. 1) of Mg-3Si-3Sn magnesium alloy without isothermal heat treatment, after adopting the method proposed by the present invention to process, the alloy structure has the shape of Chinese characters or fibrous eutectic Mg 2 Most of the Si phase has become granular, indicating that the method proposed by the present invention is used to process the Mg-3Si-3Sn magnesium all...

Embodiment 3

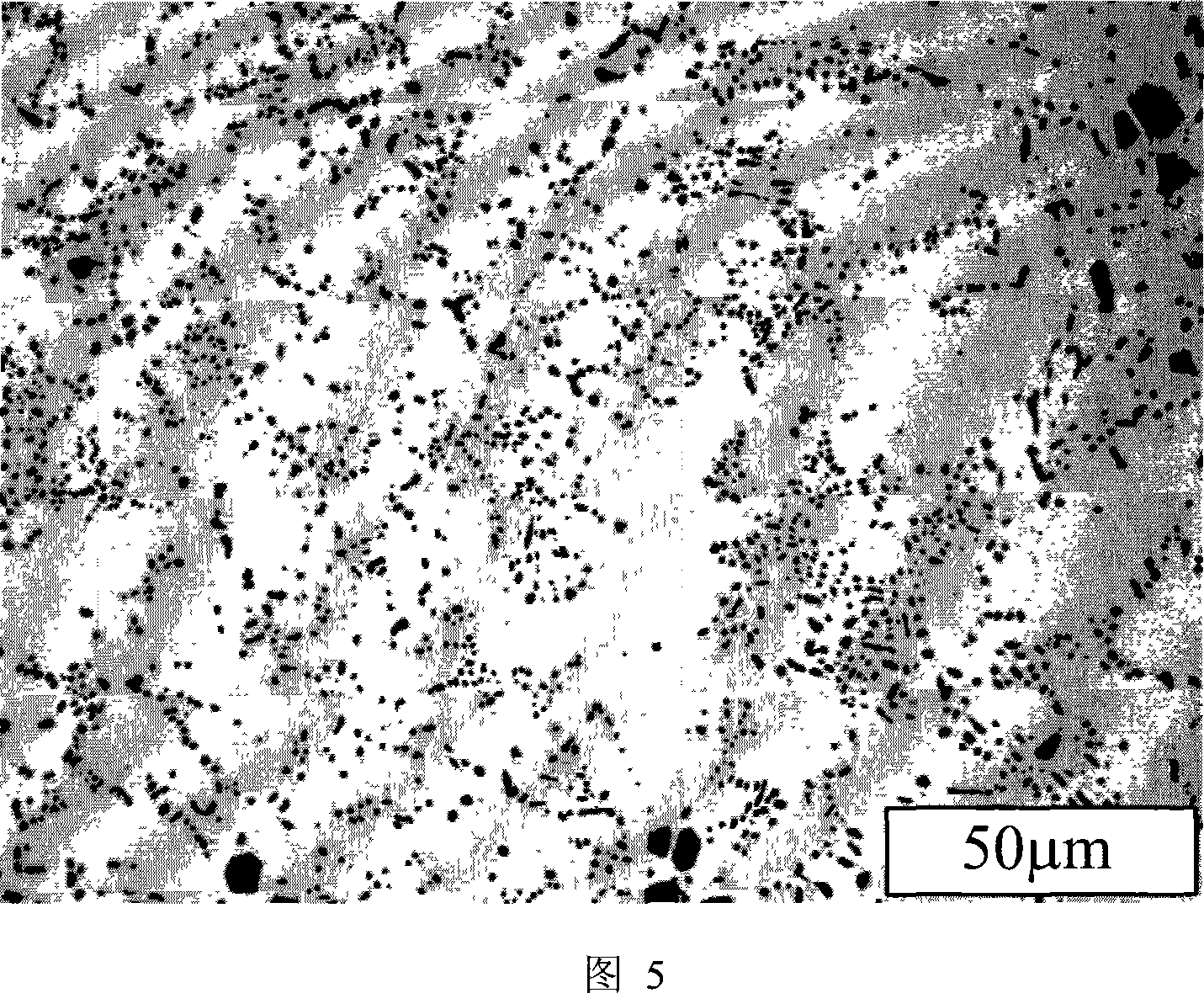

[0028] The Mg-3Si-3Sn magnesium alloy smelted according to the composition ratio is poured into a metal mold or a sand mold for gravity casting. Afterwards, the casting is kept in a box-type resistance furnace with a protective atmosphere, and then quickly taken out and put into water for quenching. The isothermal heat treatment temperature is 520 ° C, and the holding time is 2 hours. The metallographic structure analysis of the alloy obtained by adopting the present invention is shown in Figure 4. As can be seen from the figure, after adopting the method proposed by the present invention to process the alloy, the Chinese character or fibrous eutectic Mg in the alloy structure 2 Most of the Si phase has become granular, indicating that the method proposed by the present invention is used to process the Mg-3Si-3Sn magnesium alloy, which can make the Chinese character or fibrous eutectic Mg in the alloy structure 2 Si phase modification.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com