Semiconductor encapsulating epoxy resin composition and semiconductor device

A technology of epoxy resin and composition, applied in the direction of semiconductor devices, semiconductor/solid device parts, electric solid devices, etc., can solve the problems of low elastic modulus, low glass transition temperature, low expansion rate, etc., and achieve high Good glass transition temperature, good moisture resistance reliability, and small coefficient of linear expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0093] "Examples 1-6, Comparative Examples 1-4"

[0094] The components shown in Table 2 were melt-mixed with a hot twin-roller until uniform, cooled, and pulverized to obtain an epoxy resin composition for semiconductor sealing. The raw materials used are as follows.

[0095] (epoxy resin)

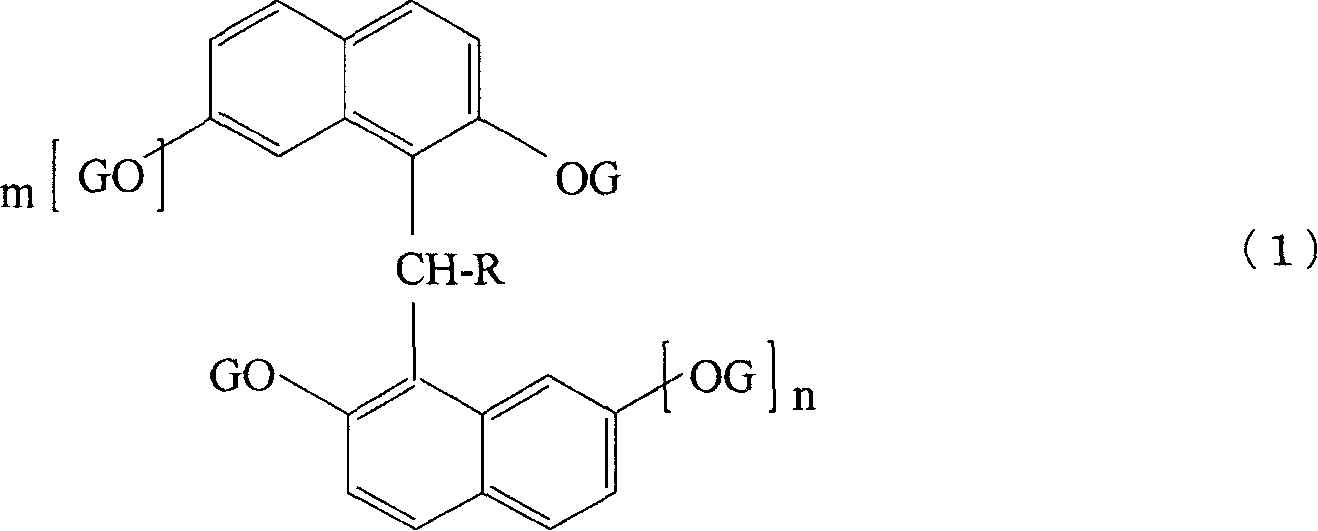

[0096] Among the epoxy resins in the above formula (1), for the following structure epoxy resins (i) to (iii) with different values of m and n, according to their compounding ratio, the epoxy resins (1) to (4) and (5) biphenyl aralkyl type epoxy resin (NC3000: trade name manufactured by Nippon Kayaku Co., Ltd.).

[0097] 【chemical 15】

[0098] For G express.

[0099] Epoxy resin (i) (m=0, n=0)

[0100] 【Chemical 16】

[0101]

[0102] Epoxy resin (ii) (m=1 and n=0, m=0 and n=1)

[0103] 【Chemical 17】

[0104]

[0105] Epoxy resin (iii) (m=1, n=1)

[0106] 【chemical 18】

[0107]

[0108] Epoxy Resin Mixing Ratio

(i)

(ii)

(iii)

Epoxy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com