High-strength pipe made by thermoplastic continuous fiber prepreg tapes and manufacturing method and manufacturing equipment

A continuous fiber, prepreg tape technology, applied in the field of pipe products, can solve the problems of insufficient rigidity of pure plastic inner pipe ring, affecting pipe rigidity, insufficient rigidity of inner plastic thin-walled pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

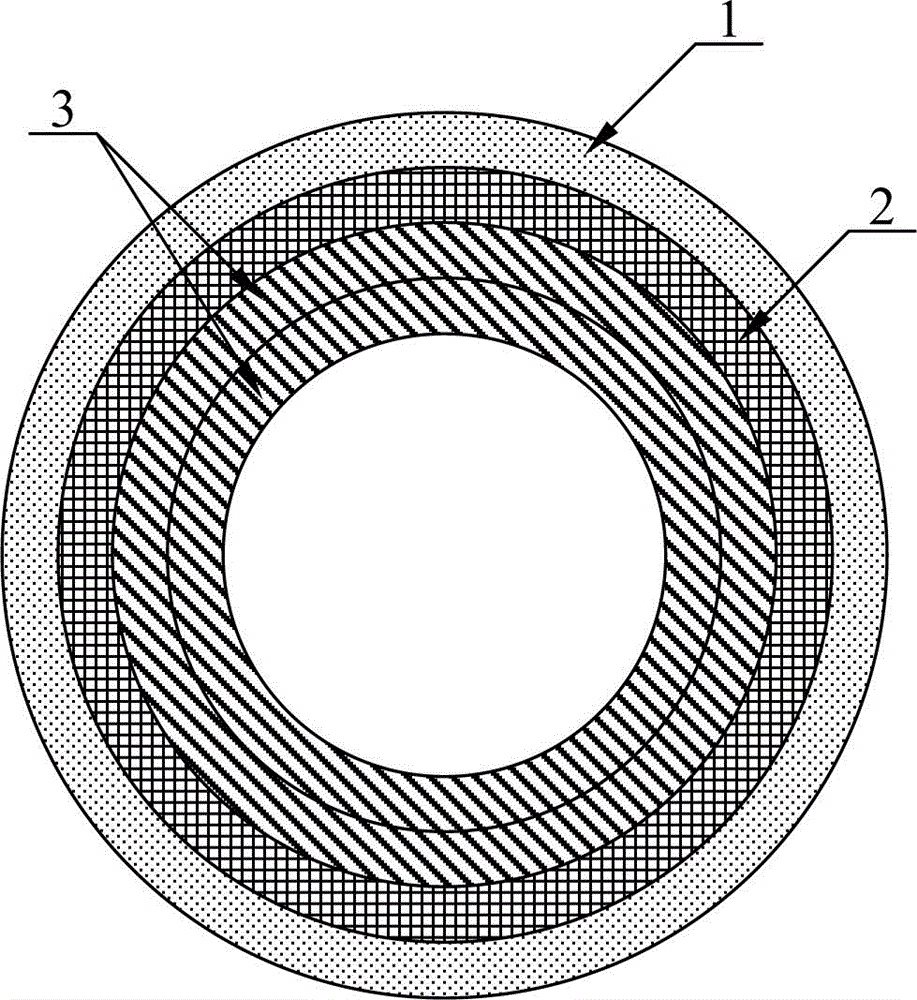

[0098] A thermoplastic continuous fiber prepreg tape high-strength pipe, including an inner layer pipe 1, a core layer 2 and a surface layer pipe 3 that are sequentially sleeved from the inside to the outside, such as figure 1 As shown, the specific structure is:

[0099] The inner tube 1 is made of melted thermoplastic and extruded. The inner tube 1 is single-layer or double-layer; the core layer 2 is made of thermoplastic continuous fiber prepreg tape, and the core tube 2 includes at least one layer; the surface layer tube 3 It is made of melted thermoplastic and extruded, and the surface layer tube 3 is solid or foamed;

[0100] When the inner tube 1 is a single layer, the wall thickness of the inner tube 1 is 2 mm to 6 mm, the material of the inner tube 1 is the same as that of the core layer 2, and the inner tube 1 is extruded by a single-screw extruder, Vacuum sizing box is made after cooling, which plays the role of winding prepreg tape inner mold and pipe inner wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com