Built-in lamella heat exchanger of welding plate

A technology of built-in plates and welded plates, applied in indirect heat exchangers, heat exchanger types, heat exchange equipment, etc., can solve the problems of high pressure and low heat exchange efficiency, can not withstand high temperature, etc., to improve application performance and avoid cracking Deformation, innovative effect of inventive concept

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

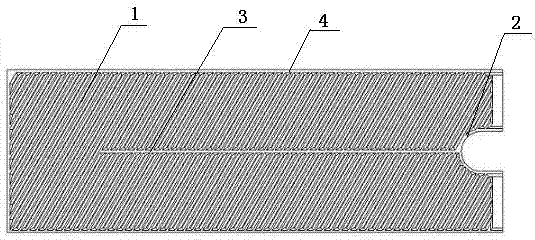

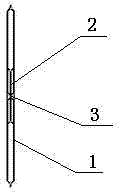

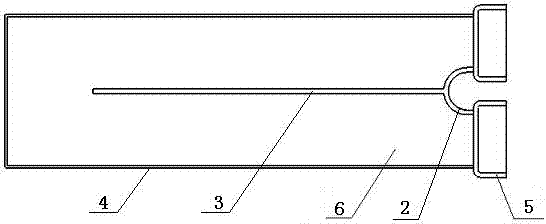

[0016] The built-in plate-shell heat exchanger of the welded plate of the present invention is a new type of heat exchange equipment designed on the basis of the prior art. Its plate is different, the corrugation on the plate is trapezoidal oblique corrugation 1, the inclination angle on both sides of trapezoidal oblique corrugation 1 is 45°, and the corrugation pitch is 15mm. A U-shaped notch 2 is provided in the center of one side of the plate, and a horizontal rib 3 extending to the corresponding side is provided at the symmetrical center of the U-shaped notch 2. On the other three sides 4 of the U-shaped notch 2 and the periphery of the plate, Set up welded edges separately. The two plates using the plates are relatively welded and crimped to the U-shaped notch 2, the horizontal rib 3 and the other three sides 4 around the plate by a seam welding machine, so that the three sides 4 are closed, and the U-shaped notch 2 is up and down. A pair of plates composed of two symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com