Silicon carbide ceramic braze welding connection method

A technology of silicon carbide ceramics and connection methods, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of small weldable workpieces, poor wettability of metal brazing filler metals, and large residual stress, and achieve the goal of microstructure. Density, good industrial application prospects, and the effect of reducing residual internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

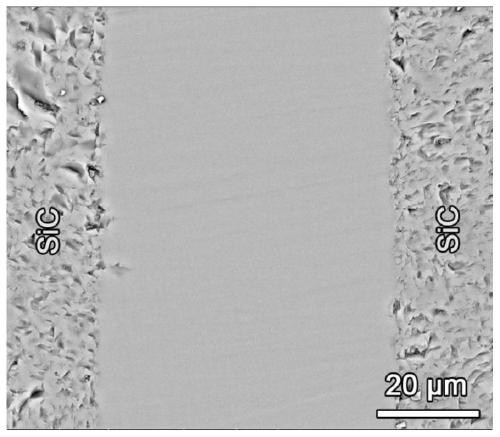

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment 1: In this embodiment, a silicon carbide ceramic brazing connection method is completed according to the following steps:

[0017] 1. According to the mass fraction Al 2 o 3 12%~15%, SiO 2 52%~63% and the balance is CaO or CaCO 3 Weigh Al respectively 2 o 3 , SiO 2 and CaO or CaCO 3 ;

[0018] 2. The Al taken in step 1 2 o 3 , SiO 2 and CaO or CaCO 3 Mixing, grinding by wet grinding method, drying treatment; melting after drying treatment, then water quenching, grinding by wet grinding method after water quenching, sieving after grinding, and drying treatment to obtain glass-ceramic brazing material;

[0019] 3. Pretreating the silicon carbide ceramics to be brazed to obtain pretreated silicon carbide ceramics;

[0020] 4. Mix the glass-ceramic solder obtained in step 2 with the binder evenly, and then evenly coat between the pretreated silicon carbide ceramics obtained in step 3 to obtain the silicon carbide ceramic connectors to be w...

specific Embodiment approach 2

[0025] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in the step one, according to the mass fraction Al 2 o 3 14.7%, SiO 2 62% and CaO23.3%, or Al 2 o 3 12.4%, SiO 2 52.4% and CaCO 3 35.2% were weighed Al 2 o 3 , SiO 2 and CaO or CaCO 3 .

[0026] Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the steps of the two wet grinding methods described in step two are as follows: use absolute ethanol as the medium, and mix the Al 2 o 3 , SiO 2 and CaO or CaCO 3 , with a speed of 550rpm mechanical ball milling for 8h ~ 10h, the mass ratio of the ball to material is 2:1.

[0028] Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com