Method for low-temperature connection of aluminum oxide ceramics through phosphate glass brazing filler

A technology of alumina ceramic and phosphate glass, applied in the field of alumina ceramic low temperature connection, can solve the problem of high welding temperature, achieve the effect of simple process, reduced residual internal stress and small residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

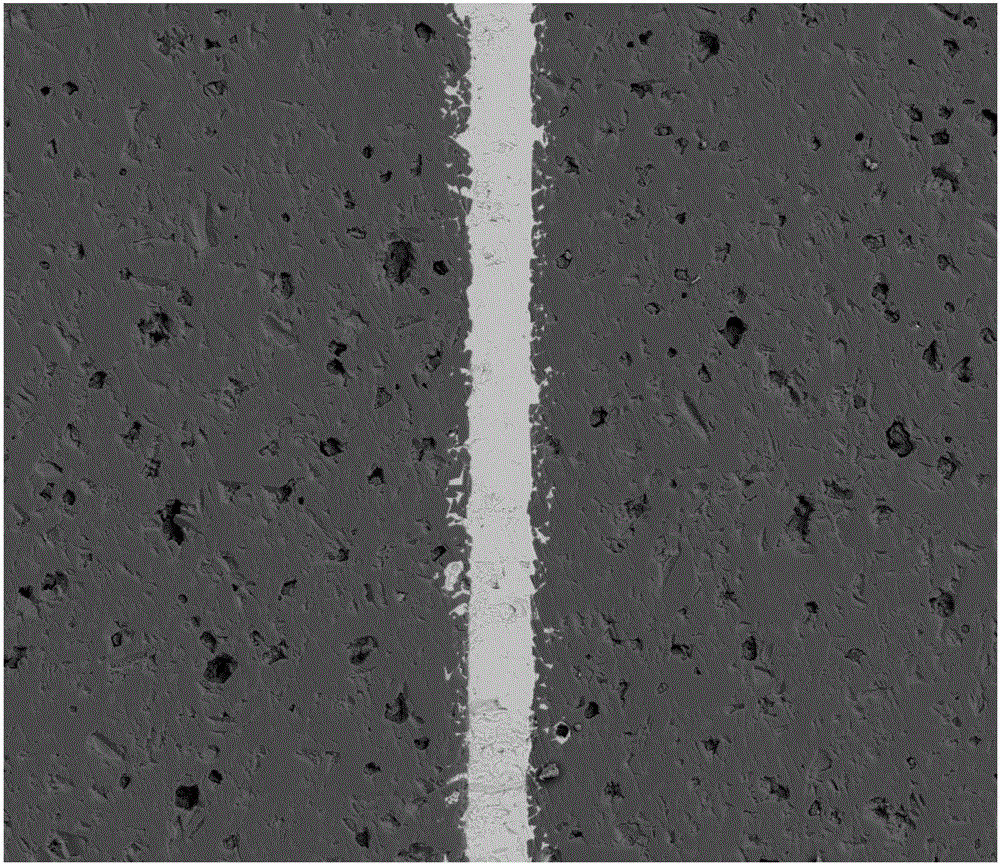

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the method for low-temperature connection of alumina ceramics with phosphate glass solder in this embodiment is implemented in the following steps:

[0019] 1. Put P 2 o 5 Powder, SnO powder, MgO or CaO powder are mixed evenly, and the uniformly mixed powder is placed in a crucible, and then the crucible is placed in a muffle furnace, heated to 1100-1300°C, heat preservation treatment to obtain molten glass, and then Water quenching to obtain glass particles, and ball milling to obtain lead-free phosphate glass powder;

[0020] 2. Mix the lead-free phosphate glass powder with the binder, and then stir evenly to obtain the glass solder paste;

[0021] 3. Use a diamond sand disc to mechanically grind the surface of the alumina ceramics to be welded, and then use acetone and absolute ethanol to ultrasonically clean them in turn to obtain the cleaned alumina ceramics;

[0022] 4. Coating glass solder paste on the surface to be welded of the clean...

specific Embodiment approach 2

[0028] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 35 to 40 parts of P 2 o 5 Powder, 40-45 parts of SnO powder and 15-25 parts of MgO powder are mixed evenly. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, 35 to 40 parts of P 2 o 5 Powder, 35-45 parts of SnO powder and 10-20 parts of CaO powder are mixed evenly. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com