Preheating heat preservation device for laser additive manufacturing

A heat preservation device and laser additive technology, which is applied in the direction of additive manufacturing, additive processing, metal material coating technology, etc., can solve the problems that it is difficult to ensure the temperature stability of the melting zone, and it is difficult to form a molten pool, so as to improve the hardness and prevent cracks and porosity, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0096] 1. The laser cladding device used in Examples 1-3 is the ZKZM-4000 laser cladding product produced by Xi'an Zhongke Zhongmei Co., Ltd., including optically coupled semiconductor lasers, chillers, cladding heads, powder feeders and other components . The formulation of the laser cladding powder used is shown in Table 1 below (mass percentage):

[0097] Table 1

[0098]

[0099]

[0100] The particle size range of the alloy material powder is 25-150 μm, and the sphericity is ≥80%.

[0101] 2. Pretreatment of copper-based workpieces

[0102] Polish the surface of the pure copper workpiece with a grinder and sandpaper to remove the surface oxide layer; and clean the surface of the pure copper workpiece with absolute alcohol or acetone to obtain a clean surface of the pure copper workpiece;

[0103] 3. Pretreatment of cladding alloy powder

[0104] The laser cladding powder needs to be dried before cladding, the drying temperature is 80-100°C, and the drying time i...

Embodiment 4-6

[0127] In order to verify the influence of the cladding head working angle on the cladding effect after powder feeding in the center, the cladding head working angle was changed, other conditions were the same as in Example 1, and the cladding results obtained by comparing different working angles were shown in Table 6 below. , corresponding to metallographic results such as Figure 7 shown.

[0128] Table 6

[0129] Example 4 Example 1 Example 5 Example 6 working angle 90 75 60 45 Cladding quality There are a few pores No pores and no cracks There are a few cracks cracked

Embodiment 7

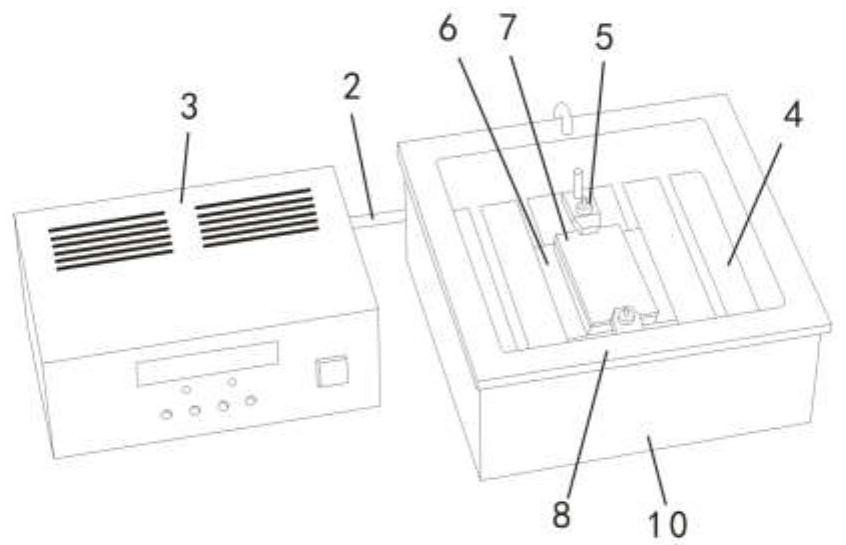

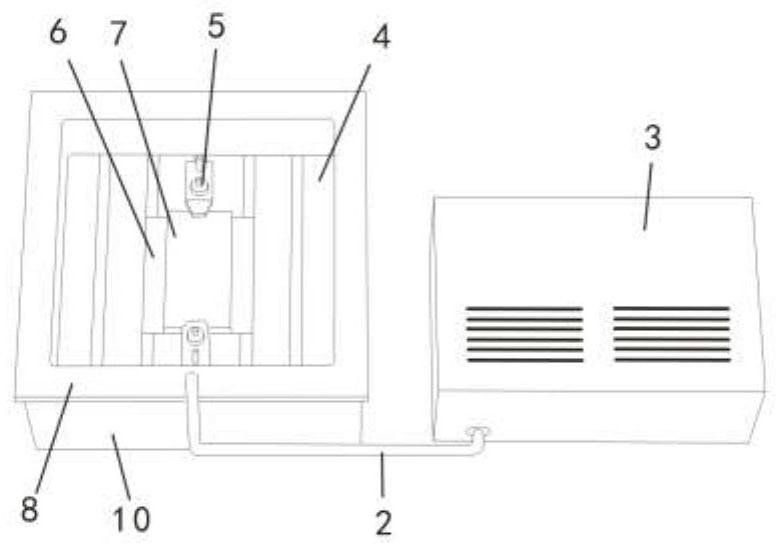

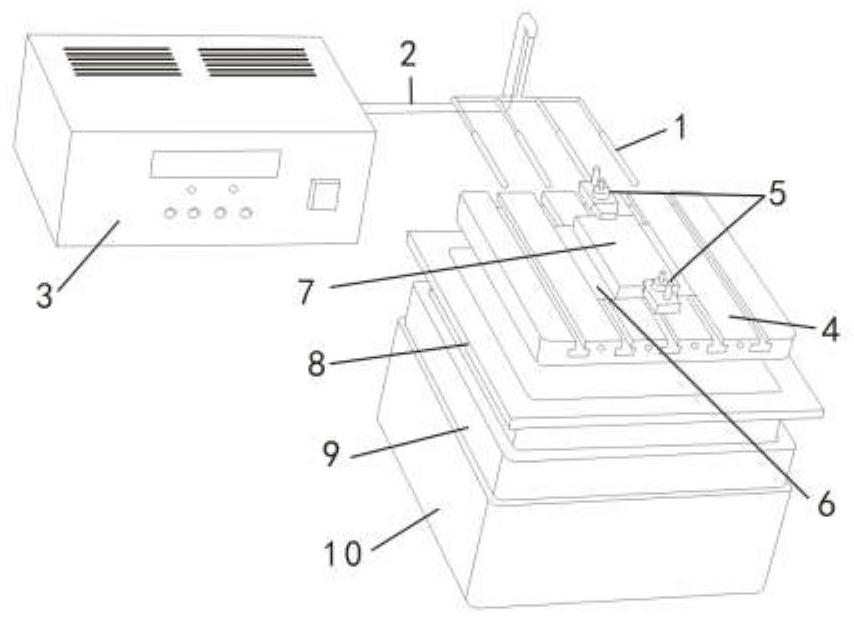

[0131] This embodiment adopts a kind of laser cladding manufacturing preheating insulation device, which consists of such as image 3 , 4 The components shown in combination form a figure 1 , 2 style shown.

[0132] The preheating and heat preservation device is set on the cladding workbench of laser material addition. The preheating and heat preservation device has a heat preservation chamber, and a heating temperature control unit and a workpiece clamping unit are arranged in the heat preservation chamber. The top of the heat preservation chamber is opened to allow the laser to act on the On the additive material, a cover is provided at the opening. During laser work, the cover is open. When the laser operation is completed and heat preservation is required, the cover is closed.

[0133] The preheating and heat preservation device includes a heating temperature control unit, a copper-based workpiece clamping platform, an upper tank body, a lower tank body and thermal in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com