Multipoint nitrogen charging injection molding technology

A multi-point, process technology, applied in the direction of coating, etc., can solve the problems of unsatisfactory appearance color of products, inconsistent wall thickness shrinkage of plastic parts, high requirements for mold equipment, etc., to achieve full appearance color, shorten molding cycle, and improve surface quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0029] Using the multi-point nitrogen-filled injection molding process of the present invention to inject a plastic product with four strips arranged in parallel in a theme, comprises the following steps:

[0030] Step (1): In the mold clamping state, form 4 mold cavities arranged in parallel in the form of long strips, and the four sides of the long strips are provided with large rounded corners to avoid stress concentration during the injection molding process. The plastic melt enters the mold cavity from the mold gate, and the plastic melt meets the lower temperature mold wall to form a thinner solidified layer.

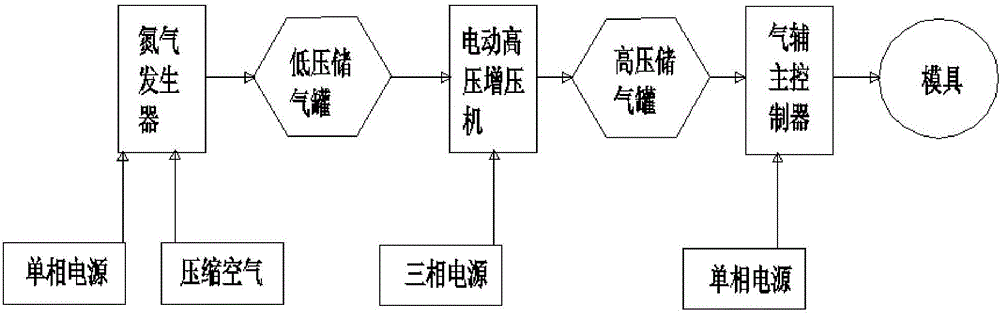

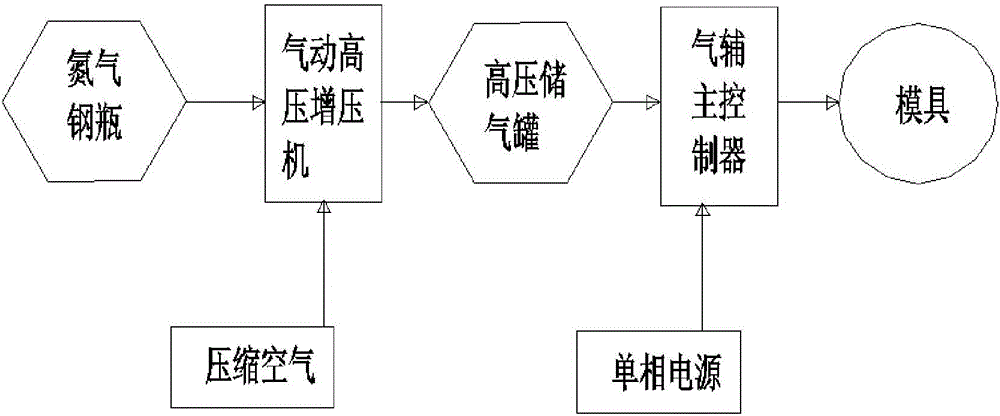

[0031] Step (2): The mold is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com