Embedding riveting bracket for connecting automobile interior instrument board with safe air bag cabin

A technology for airbags and automotive interiors, applied in vehicle safety arrangements, pedestrian/passenger safety arrangements, vehicle components, etc., can solve the problem of increasing the manufacturing cost of interior dashboards, high manufacturing costs, and affecting the surface appearance quality of interior dashboards And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

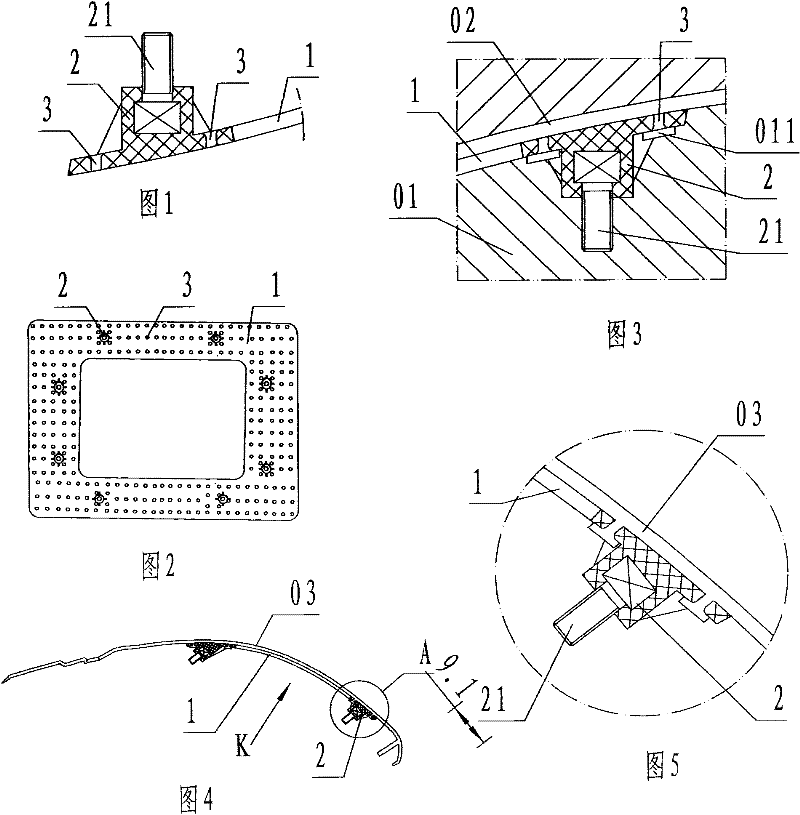

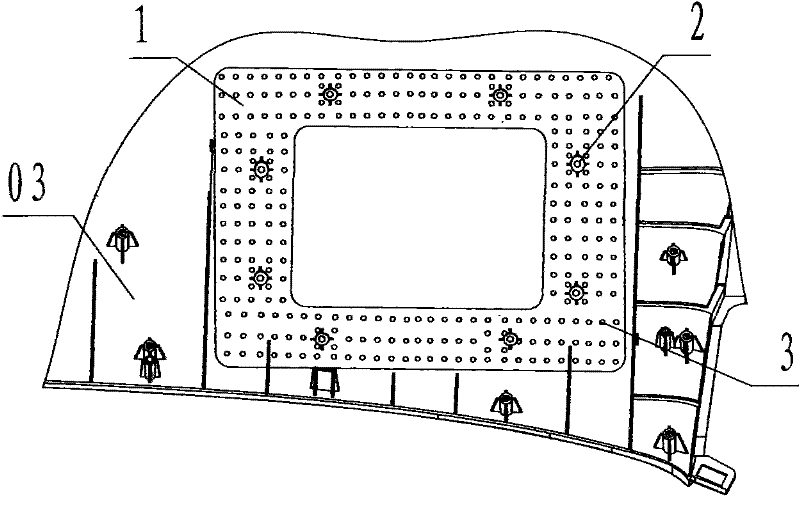

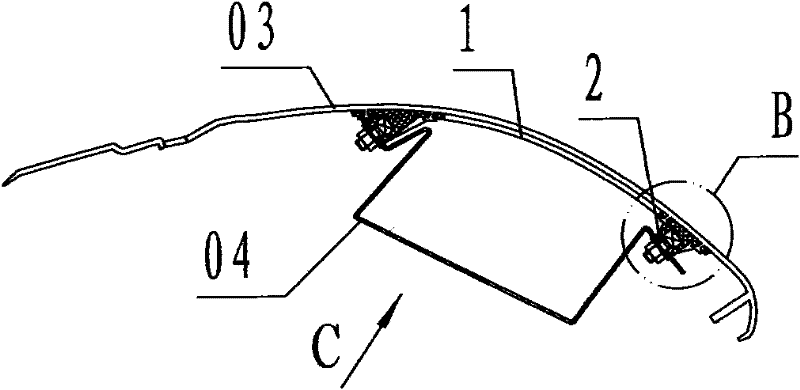

[0024] refer to Figure 1 to Figure 9 , a kind of embedded riveting bracket of the automobile interior dashboard connected to the airbag compartment of the present invention, including the embedded riveting bracket and the connection method with the interior dashboard, wherein: the embedded riveting bracket is composed of a frame seat 1, a bolt column 2. A plastic prefabricated insert composed of pre-embedded bolts 21 and perforations 3; wherein, the frame seat 1 is a bottom frame with a rectangular annular thin-walled curved surface; The curved profiles match; there are several upwardly protruding, cylindrical bolt posts 2 on the top of the frame seat 1, and metal pre-embedded bolts 21 are pre-embedded in the center of the top of the bolt post 2; Circular perforations 3 on the upper and lower sides of the frame seat 1; around the peripheral position of the bolt column 2, the density of the perforations 3 is slightly larger;

[0025] The connection method with the interior in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com