Injection molding process for eliminating shrinkage marks and shrinkage cavities of thick-wall light guide piece during manufacturing of automobile lamps

A technology for automotive lamps and light guides is applied in the field of making thick-walled light guides eliminate their shrinkage marks and shrinkage holes during the injection molding process. The effect of reducing production cycle and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

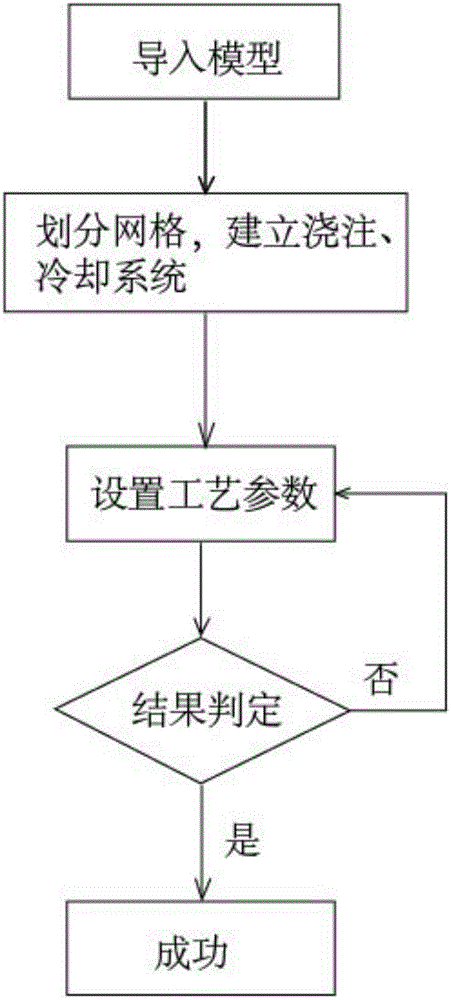

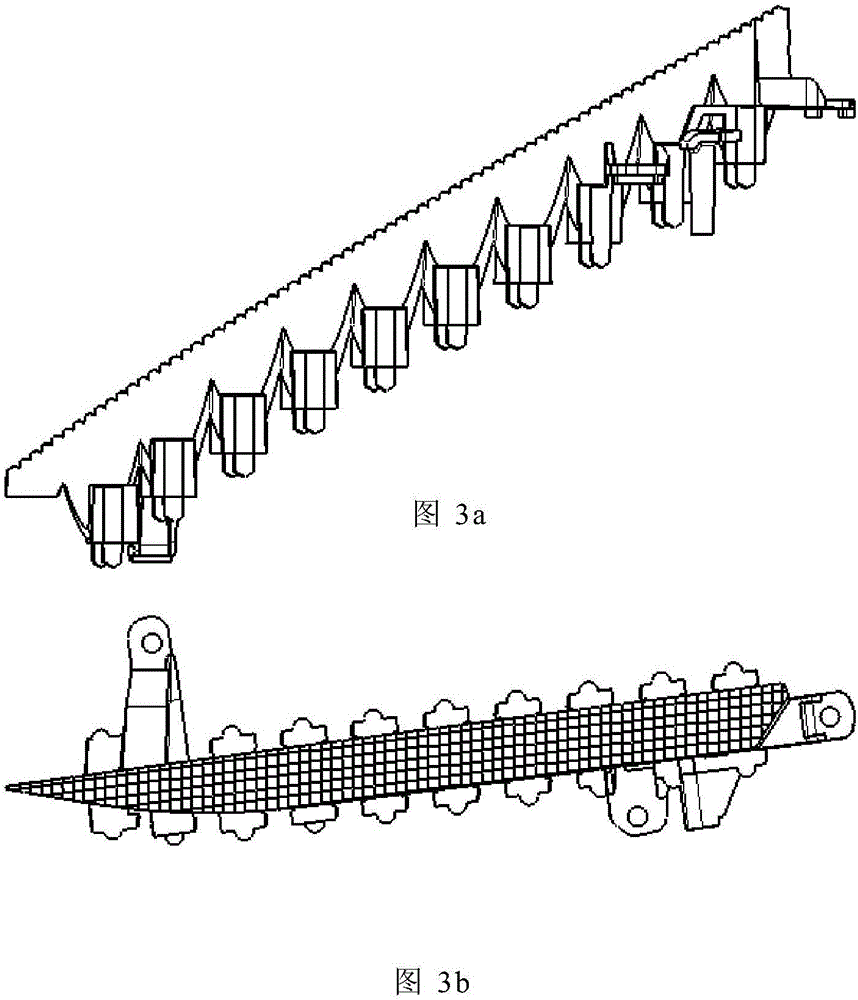

[0030] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

[0031] The invention aims to provide an injection molding process scheme for a light distribution mirror in a thick-walled light guide, which solves the phenomenon of sink marks and shrinkage cavities caused by too much shrinkage during injection molding of the thick-walled light guide.

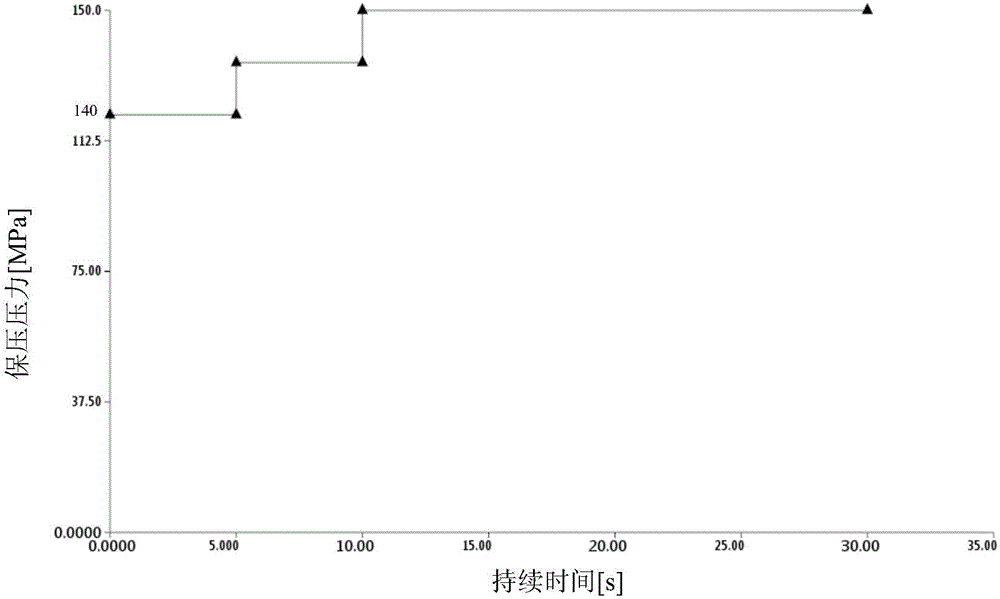

[0032] With the help of MOLDFLOW software, the PC thick-walled light guide with a thickness between 10mm and 15mm was analyzed and simulated multiple times, and the optimal injection molding process was found by continuously optimizing the process parameters. When the product is opened, the internal volume shrinkage rate does not exceed 5% (that is, the volume shrinkage rate at the 1 / 4 wall thickness does not exceed 5%), and the adjacent shrinkage rate does not exceed 2%. Good solidification to avoid sink marks and shrinkage cavities. Then it solves the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com