Dash board with integrated safety airbag cover

A technology of airbags and instrument panels, applied in the field of fixed protection systems for front seat occupants, which can solve problems such as aggravated failures, expensive production of instrument panels, and limited strength of press-fit connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

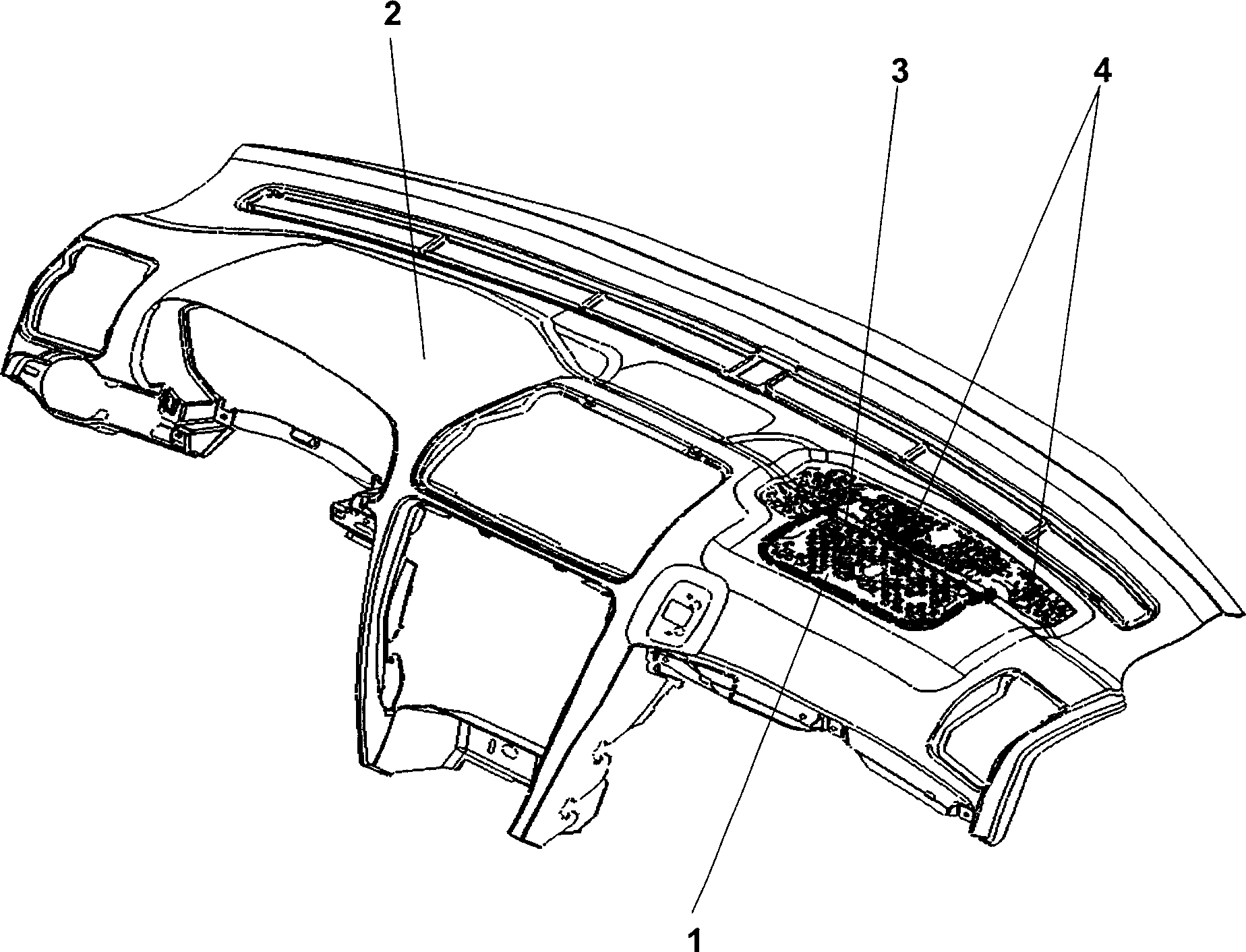

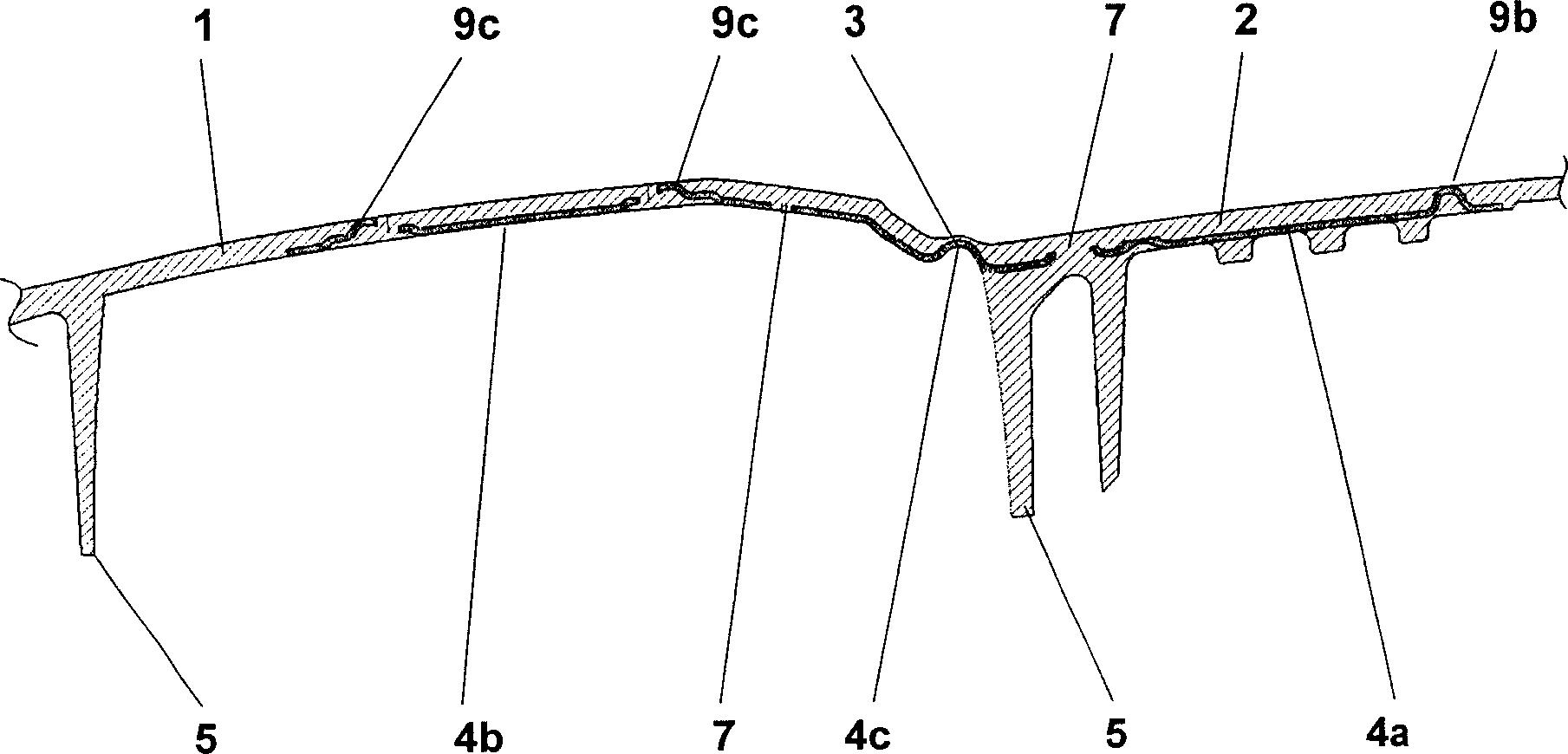

[0018] Reinforcement panel 2 with integral airbag cover 1, comprising a metal reinforcement 4, the panel is made of a polypropylene based material by injection molding into a metal mold, wherein during the manufacturing process, the reinforcement 4 is first inserted Into the cavity of a reinforced panel 2 mold, after closing the mold, the reinforcement 4 is wrapped by the material of the molten reinforced panel 2, which fills the entire mold cavity.

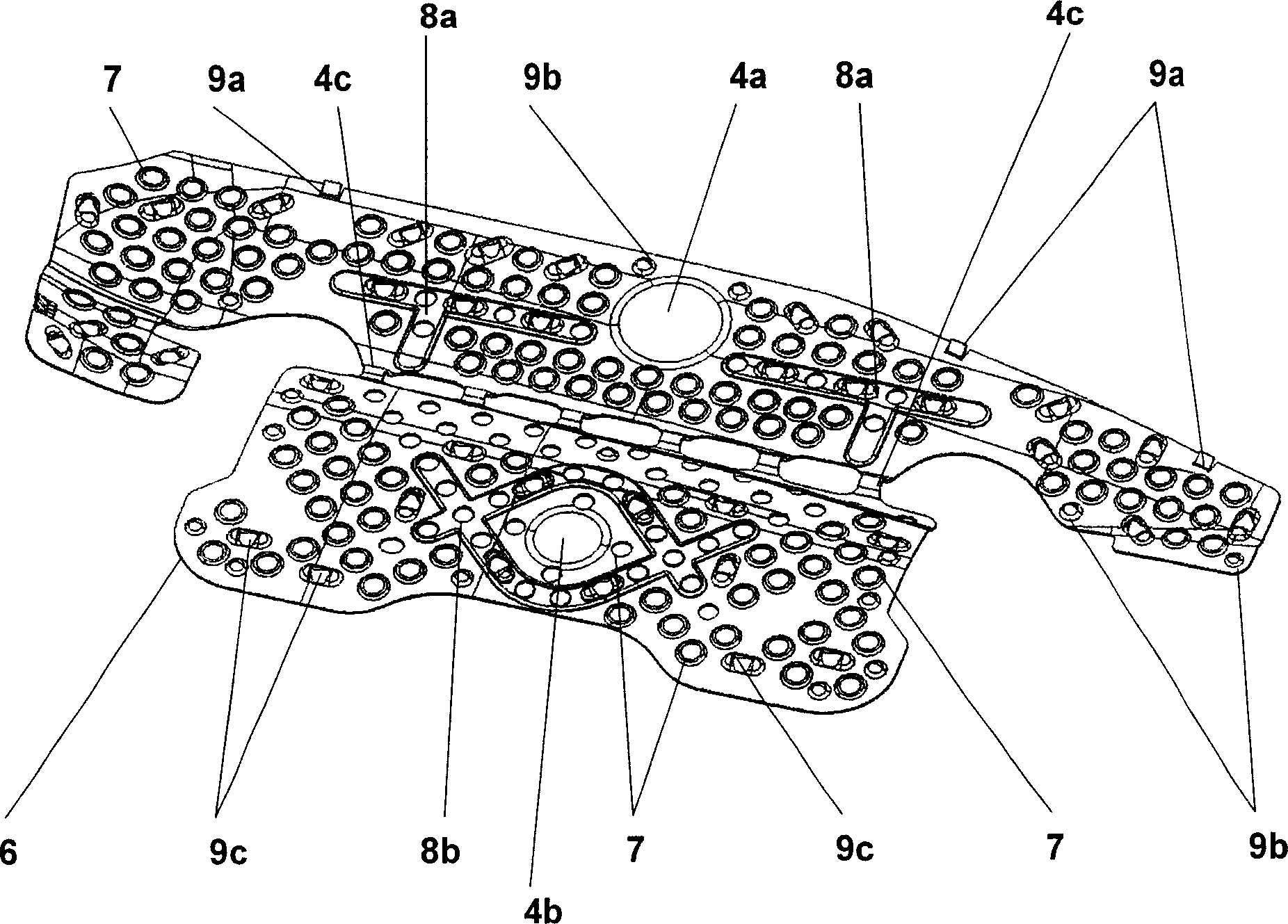

[0019] Thus, the stamped sheet metal reinforcement 4 not only has openings 7 and profiled protrusions 8a, 8b on its two parts 4a, 4b, but also positioning bosses 9a, 9b, 9c to fix the reinforcement 4 in the injection mold. The correct position in order to prevent the reinforcing member 4 from deviating from its accurate predetermined position during the injection of the melt. For this reinforcement design, the locating bosses 9a, 9b, 9c come in three different styles: the edge locating boss 9a is an outwardly bent strip stamped o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com