Seamless steel pipe formed by cold rolling and manufacturing method thereof

A seamless steel pipe, cold rolling technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of reduced bearing capacity, blocked grouting sleeves, cold brittleness, and increased micro-crack defects. Achieve the effects of small amount of mechanical cutting, reliable force transmission and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

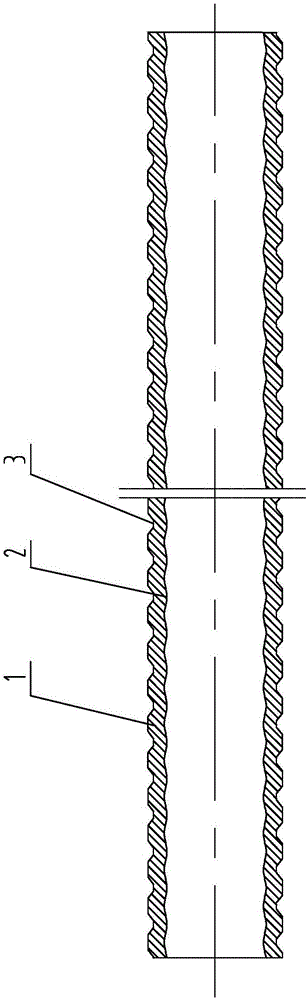

[0083] Example 1, see figure 1 , is a kind of seamless steel pipe 1 formed by cold rolling of the present invention, which is made by reducing the diameter of rolls with uniformly distributed protrusions on the surface, and the outer surface is provided with a spiral groove 3 around its axis. The lead or pitch of the groove 3 on the axis of the seamless steel pipe 1 is 5 mm to 30 mm, the inner surface of the seamless steel pipe 1 has concave and convex corrugations 2, and the maximum outer diameter is between 25 mm and 100 mm. The thickness ratio is between 6 and 16, and the maximum outer diameter of the formed seamless steel pipe 1 is 0.950 to 0.995 times the outer diameter of the seamless steel pipe blank 13 before cold rolling. The material of the seamless steel pipe 1 is high-quality carbon structural steel or low alloy structural steel or alloy structural steel, and the yield strength of the material at room temperature is not less than 345 MPa.

Embodiment 2

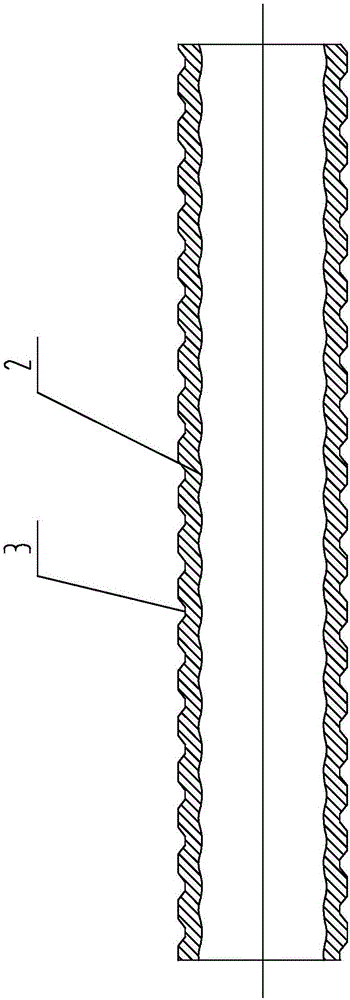

[0084] Example 2, see figure 2 , is a kind of FRP bar or ribbed steel grouting connection sleeve 4 processed by the formed seamless steel pipe 1 of the present invention, the outer surface is provided with a spiral groove 3 around its axis, and the inner surface has concave-convex corrugations 2.

Embodiment 3

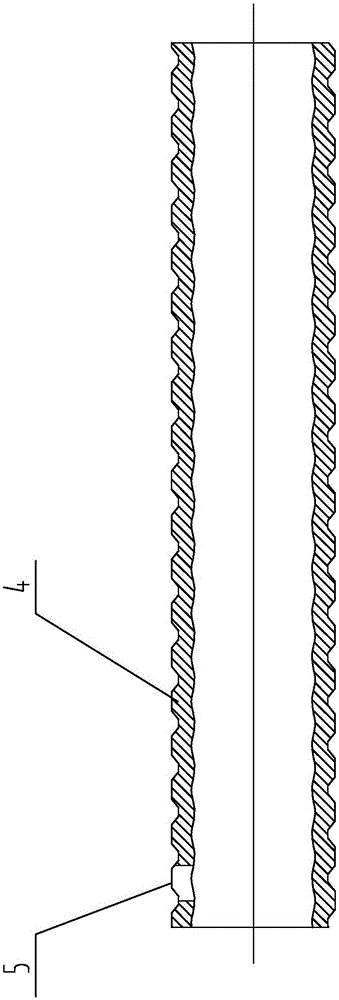

[0085] Example 3, see image 3 , is a kind of FRP bar or ribbed steel grouting connection sleeve 4 processed by the formed seamless steel pipe 1 of the present invention, the outer surface is provided with a spiral groove 3 around its axis, and the inner surface has concave-convex corrugations 2. One or more grout holes 5 for grouting or grouting into the sleeve are provided on the side wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com