Method and equipment for flexible forming of straight seam submerged arc welded pipe

A technology of straight seam submerged arc welding and flexible forming, which is applied in the field of straight seam submerged arc welded pipe forming, can solve the problems of market sales restrictions, high cost of steel pipes, and huge equipment, so as to reduce residual internal stress, reduce roll replacement, and avoid friction The effect of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

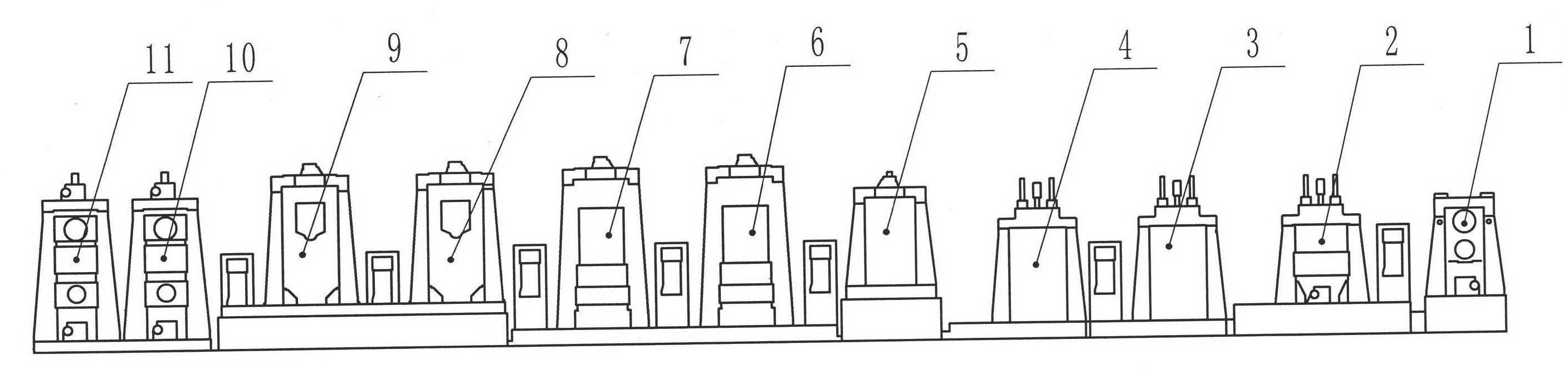

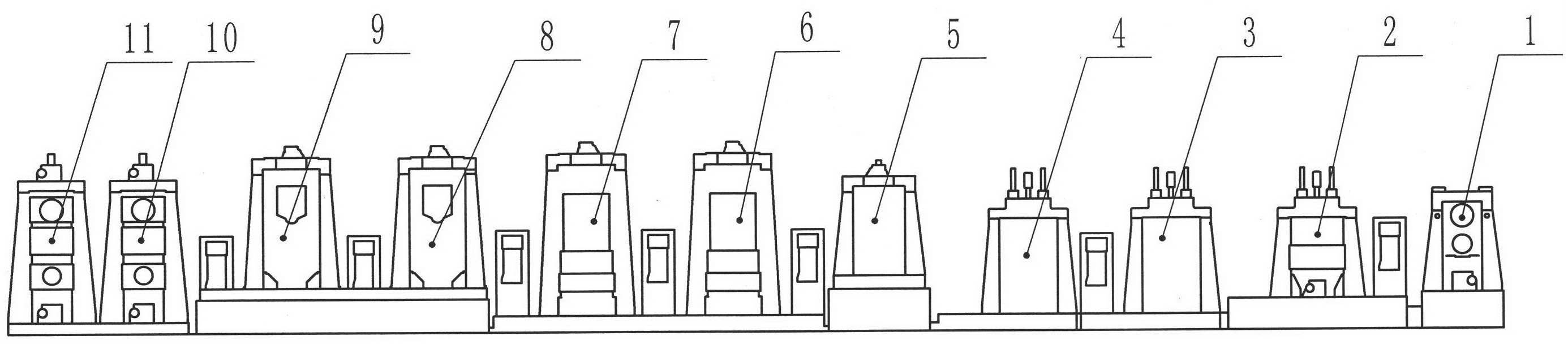

[0016] A method for flexible forming of straight seam submerged arc welded pipes, which adopts the method of fixing the center and extruding the edges. First, two bends are extruded by a flat roller frame, and then gradually extruded by four four-roller frames. U-shape, then extruded into a C-shape by four C-type vertical roller stands, and finally extruded into an open O-shape by two four-roller stands.

[0017] Such as figure 1 As shown, a kind of equipment for flexible forming of straight seam submerged arc welded pipes, according to the order in which steel coils enter: the first flat roll frame 1, the first four-roll frame 2, the second four-roll frame 3, the first Three-four roller frame 4, the fourth four-roll frame 5, the first C-shaped vertical roller frame 6, the second C-shaped vertical roller frame 7, the third C-shaped vertical roller frame 8, the fourth C-shaped vertical roller frame Roll frame 9, fifth four-roll frame 10 and sixth four-roll frame 11. Among the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com