Thick film thermistor slurry, preparation method thereof and thick film thermistor

A thick-film thermal and resistive paste technology, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, resistors with negative temperature coefficients, etc. Deterioration of varistor performance, increase in cost and other problems, to achieve the effect of simplifying production process, reducing production cost and excellent resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Preparation of thick film thermistor paste

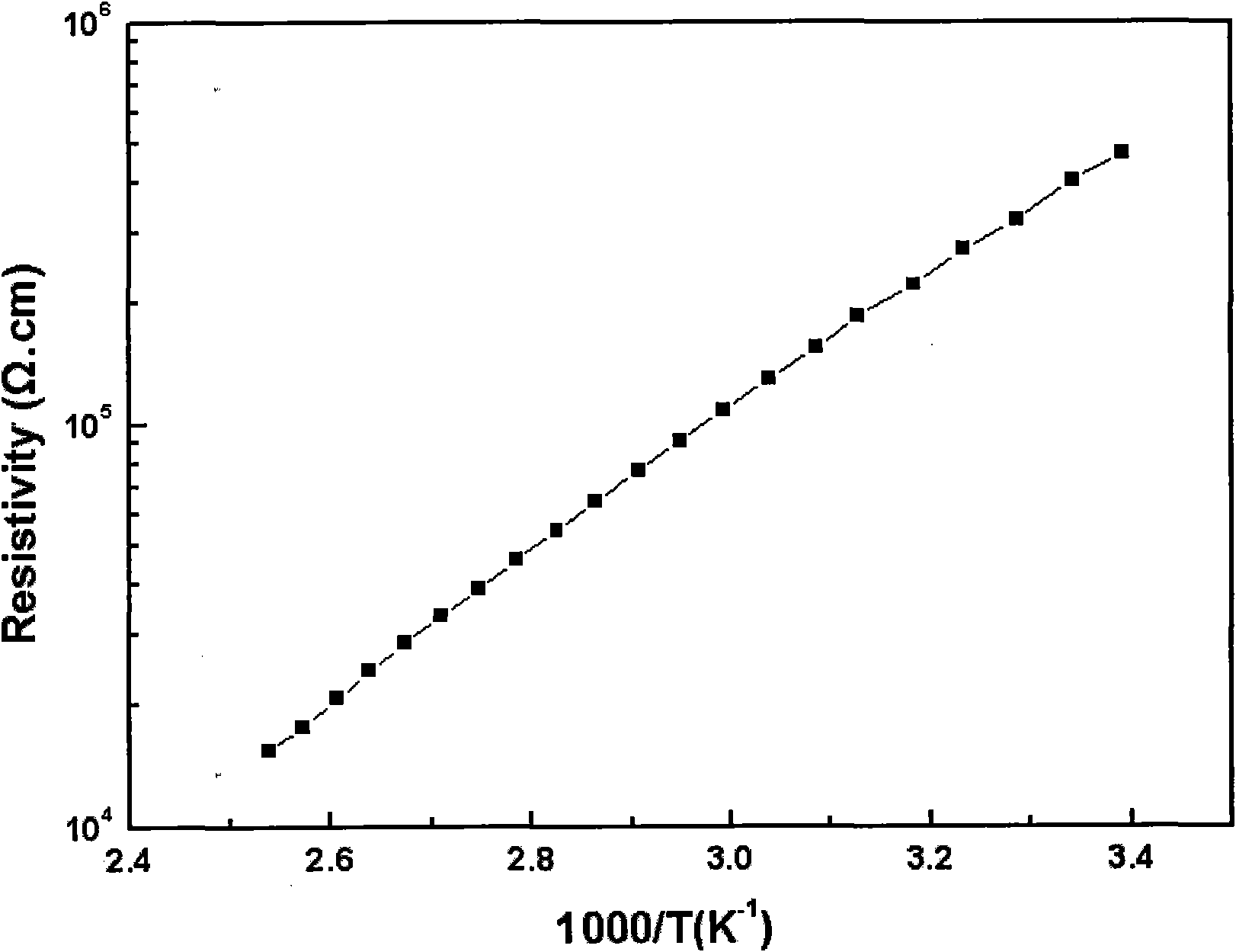

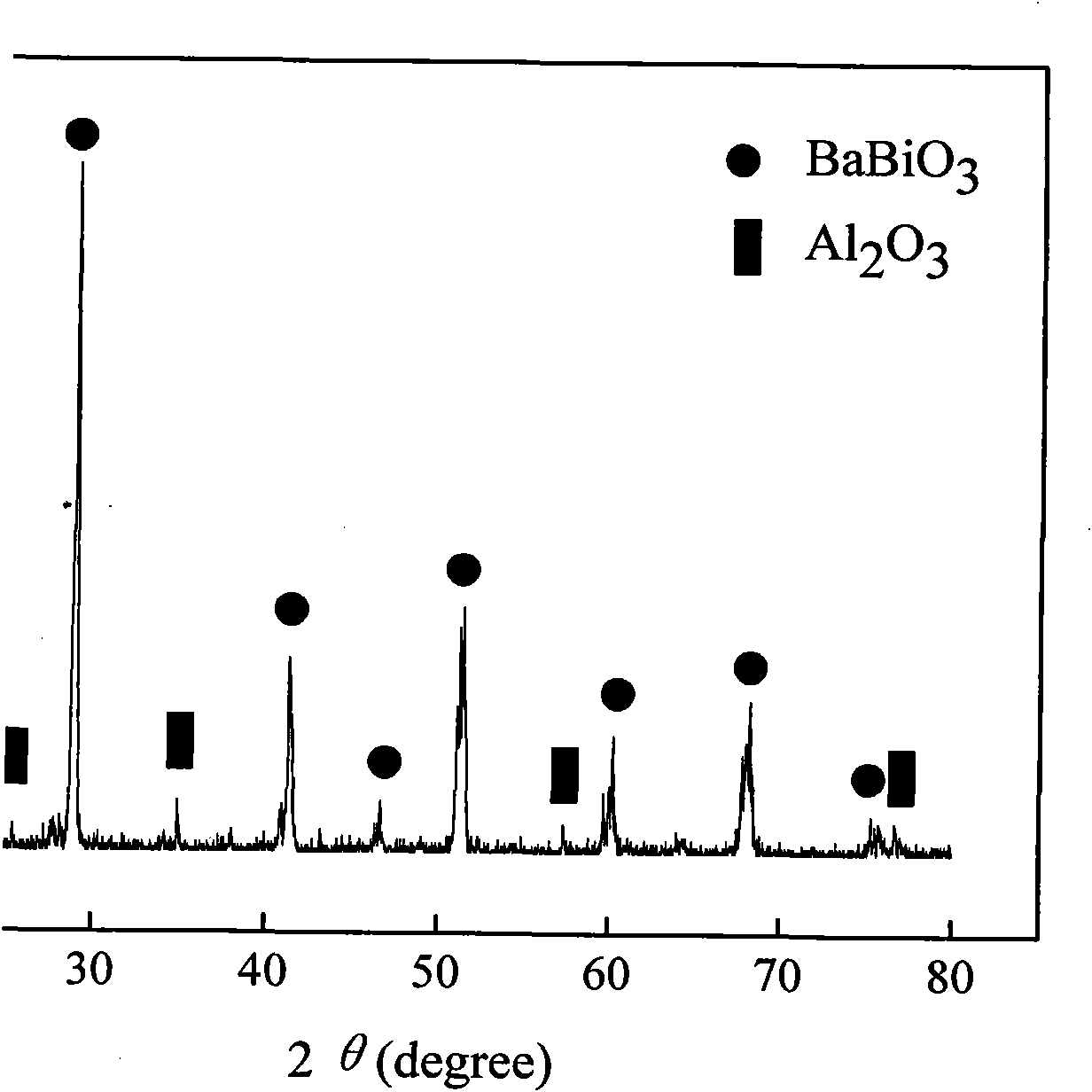

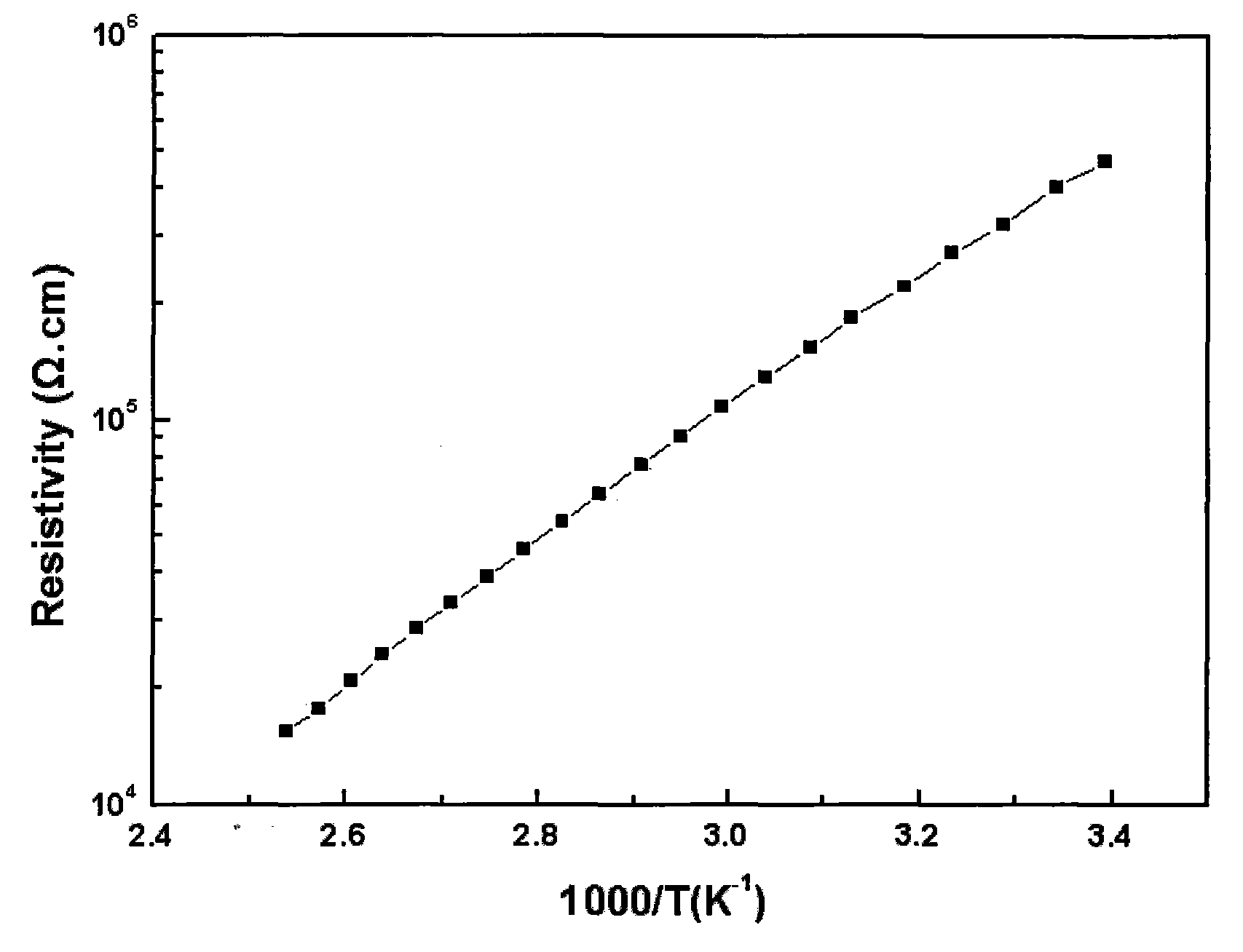

[0021] 1) Preparation of functional phase: with Bi 2 o 3 、BaCO 3 and Y 2 o 3 as the raw material, according to the composition expression (Ba 0.999 Y 0.001 ) BiO 3 Carry out batching, be the standard of 1:1:2 to add agate ball and deionized water with the mass ratio of ball, material, water, carry out mixing with ball mill ball milling 8 hours, roast at 800 ℃ after drying, heat preservation 4 hours; Then The roasted (Ba 0.999 Y 0.001 ) BiO 3 Ball milling into nano-scale powder;

[0022] 2) Preparation of organic carrier solvent: Weigh 65% terpineol, 12% ethyl cellulose, 1% lecithin and 22% hydrogenated castor oil by weight percentage and dissolve in water at 90-100°C for 5 hours;

[0023] 3) Prepare the slurry: mix the functional phase components and the organic carrier solvent in a weight ratio of 60-80:20-40, and roll with rolls to obtain the product.

[0024] 2. Preparation of thick film thermistor:

[0025...

Embodiment 2

[0027] Same as Example 1, the difference is that Bi 2 o 3 、BaCO 3 and Y 2 o 3 As raw material, preparation (Ba 0.997 Y 0.003 ) BiO 3 Functional phase powder. Table 1 lists the test results.

Embodiment 3

[0029] Same as Example 1, the difference is that Bi 2 o 3 、BaCO 3 and Y 2 o 3 As raw material, preparation (Ba 0.995 Y 0.005 ) BiO 3 Functional phase powder. Table 1 lists the test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com