A kind of negative temperature coefficient thermistor material and preparation method thereof

A negative temperature coefficient, thermistor technology, applied in the direction of resistors with negative temperature coefficient, etc., can solve the problems of limiting the application of spinel thermistors, low room temperature resistivity of thermistors, and low room temperature resistivity , to achieve good NTC characteristics, wide temperature range and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of Negative Temperature Coefficient Thermistor Material Ce 0.9 mn 0.9 Si 0.1 o 3.8 (x=0.9). The preparation method is: weigh the analytically pure CeO according to the stoichiometric ratio 2 , MnO 2 and SiO 2 , mix, add deionized water ball mill for 4 hours, dry at 90°C for 12 hours; pre-burn at 980°C for 3 hours, ball mill and dry again, add 8wt% PVA with a concentration of 5mol% and mix evenly, pass through an 80-mesh sieve to make Granules, dry-pressed at 180Mpa; sintered at 1180°C for 3 hours, and cooled with the furnace to obtain a negative temperature coefficient thermistor material.

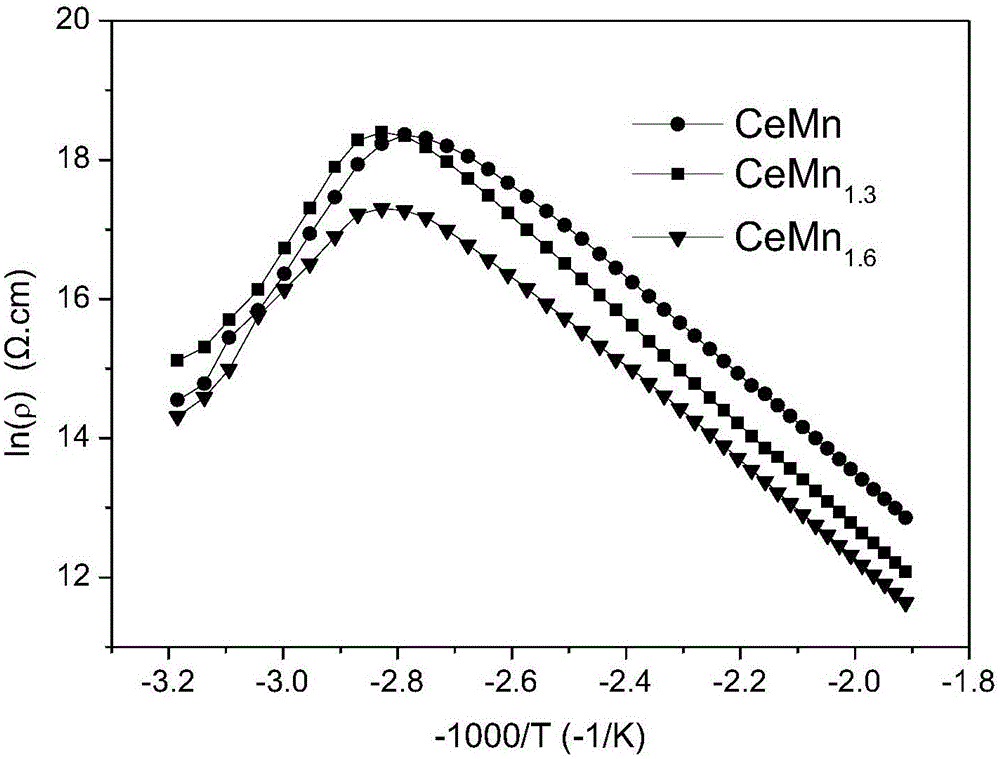

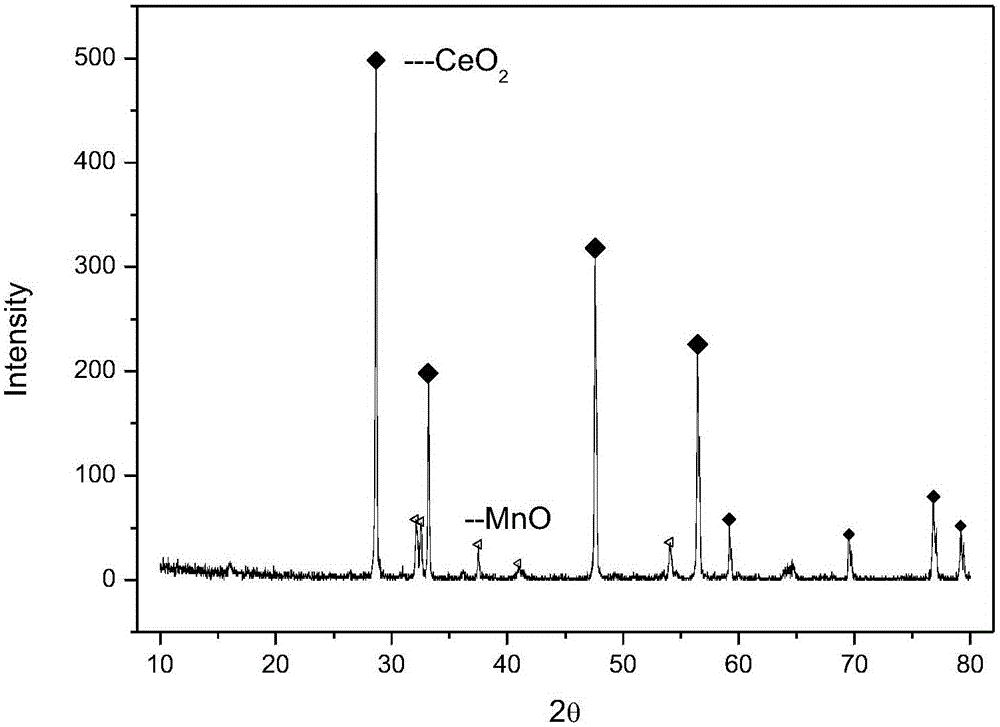

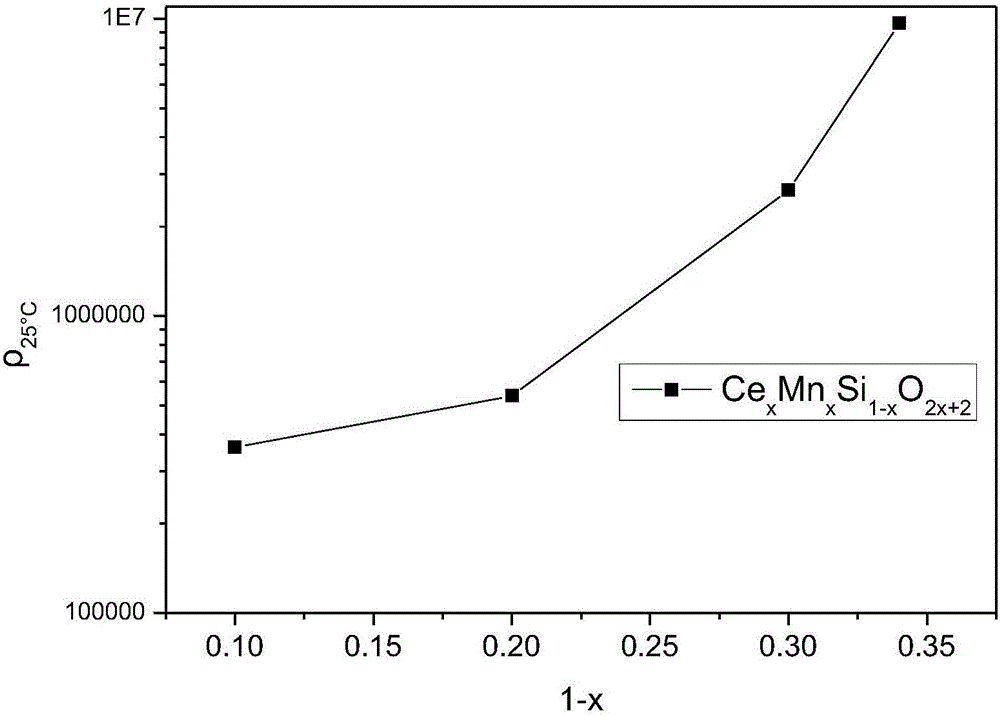

[0025] Carry out XRD test to the material that makes, the result is as follows figure 2 As shown, the material has CeO 2 The two main crystal phases of MnO and MnO, the interdiffusion between the composite phase components makes their properties compensate each other, which can improve the high temperature stability of the material. CeO 2 The strength of the p...

Embodiment 2

[0027] Preparation of Negative Temperature Coefficient Thermistor Material Ce 0.8 mn 0.8 Si 0.2 o 3.6 (x=0.8). The preparation method is: weigh the analytically pure CeO according to the stoichiometric ratio 2 , MnO 2 and SiO 2 , mix, add deionized water ball mill for 4 hours, dry at 90°C for 12 hours; pre-burn at 980°C for 3 hours, ball mill and dry again, add 8wt% PVA with a concentration of 5mol% and mix evenly, pass through an 80-mesh sieve to make Granules, dry-pressed at 180Mpa; sintered at 1170°C for 3 hours, and cooled with the furnace to obtain a negative temperature coefficient thermistor material.

Embodiment 3

[0029] Preparation of Negative Temperature Coefficient Thermistor Material Ce 0.7 mn 0.7 Si 0.3 o 3.4 (x=0.7). The preparation method is: weigh the analytically pure CeO according to the stoichiometric ratio 2 , MnO 2 and SiO 2 , mix, add deionized water ball mill for 4 hours, dry at 90°C for 12 hours; pre-burn at 980°C for 3 hours, ball mill and dry again, add 8wt% PVA with a concentration of 5mol% and mix evenly, pass through an 80-mesh sieve to make Granules, dry-pressed at 180Mpa; sintered at 1160°C for 3 hours, and cooled with the furnace to obtain a negative temperature coefficient thermistor material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com