Lead-free bismuthate system low-melting-point glass powder and preparation method thereof

A low-melting-point glass, lead-free bismuthate technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of unstable chemical properties, limited use, high cost of glass, and improve the chemical stability of glass. , Improve glass performance, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) At room temperature, take by weighing 74.44 grams of bismuth oxide (30%), 39.72 grams of boric acid (introducing 60% boric oxide), 3.19 grams of silicon oxide (10%), 4.27 grams of sodium carbonate (introducing 2.50Wt% sodium oxide), 3.67 grams of potassium carbonate (introduced with 2.50 wt% potassium oxide), stirred and ground in a mortar for 5 minutes until uniform. (2) Pour the above mixture into a corundum crucible with a capacity of 200ml, and place the crucible in the high-temperature box-type furnace after the actual temperature in the chamber of the high-temperature box-type furnace rises to 1100°C and is stable. (3) After 60 minutes of heat preservation, quickly pour a small part of the clear and transparent glass liquid into a stainless steel container filled with deionized water; pour the other part of the clear and transparent glass liquid into a graphite mold that has been preheated at 480°C for 1 hour. And quickly moved to a muffle furnace with a tempe...

Embodiment 2

[0033] (1) At room temperature, take by weighing 91.19 grams of bismuth oxide (60%), 12.17 grams of boric acid (introducing 30% boric oxide), 1.96 grams of silicon oxide (10%), 4.27 grams of sodium carbonate (introducing 2.50Wt% sodium oxide), 3.67 grams of potassium carbonate (introduced with 2.50 wt% potassium oxide), stirred and ground in a mortar for 5 minutes until uniform. (2) Pour the above-mentioned mixture into a corundum crucible with a capacity of 200ml. After the actual temperature in the chamber of the high-temperature box-type furnace rises to 1100°C and is stable, place the crucible in the high-temperature box-type furnace. (3) After keeping warm for 50 minutes, quickly pour a small part of the clear and transparent glass liquid into a stainless steel container filled with deionized water; pour the other part of the clear and transparent glass liquid into a graphite mold that has been preheated at 450°C for 1 hour, And quickly moved to a muffle furnace with a te...

Embodiment 3

[0035] (1) At room temperature, take by weighing 82.70 grams of bismuth oxide (40%), 16.55 grams of boric acid (introducing 30% boron oxide), 7.99 grams of silicon oxide (30%), 1.71 grams of sodium carbonate (introducing 1.00Wt% sodium oxide), 1.47 grams of potassium carbonate (introduced with 1.00 wt% potassium oxide), and 3.00 grams of tellurium oxide were stirred and ground in a mortar for 5 minutes until uniform. (2) Pour the above-mentioned mixture into a corundum crucible with a capacity of 200ml. After the actual temperature in the chamber of the high-temperature box-type furnace rises to 1100°C and is stable, place the crucible in the high-temperature box-type furnace. (3) After 90 minutes of heat preservation, quickly pour a small part of the clear and transparent glass liquid into a stainless steel container filled with deionized water; pour the other part of the clear and transparent glass liquid into a graphite mold that has been preheated at 480°C for 1 hour , and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

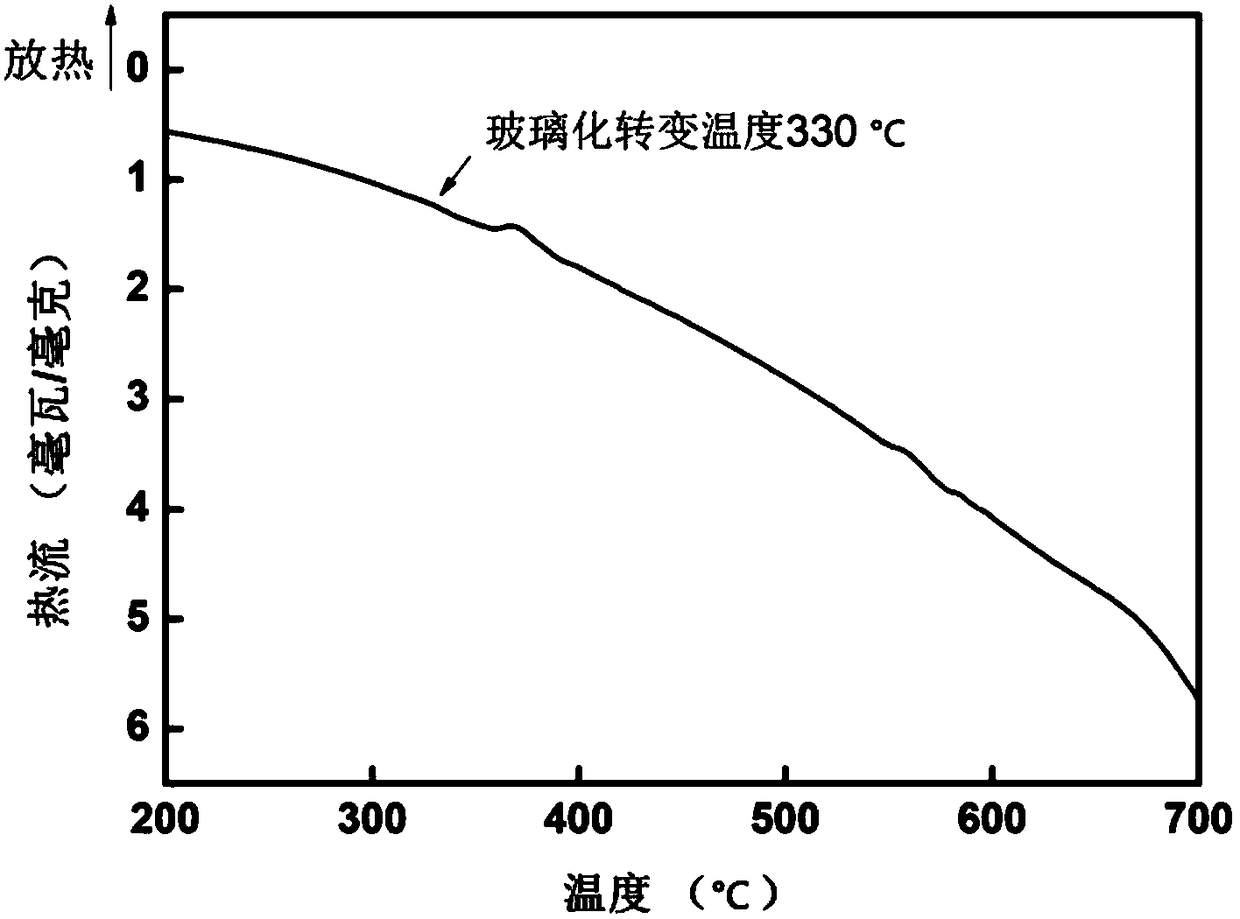

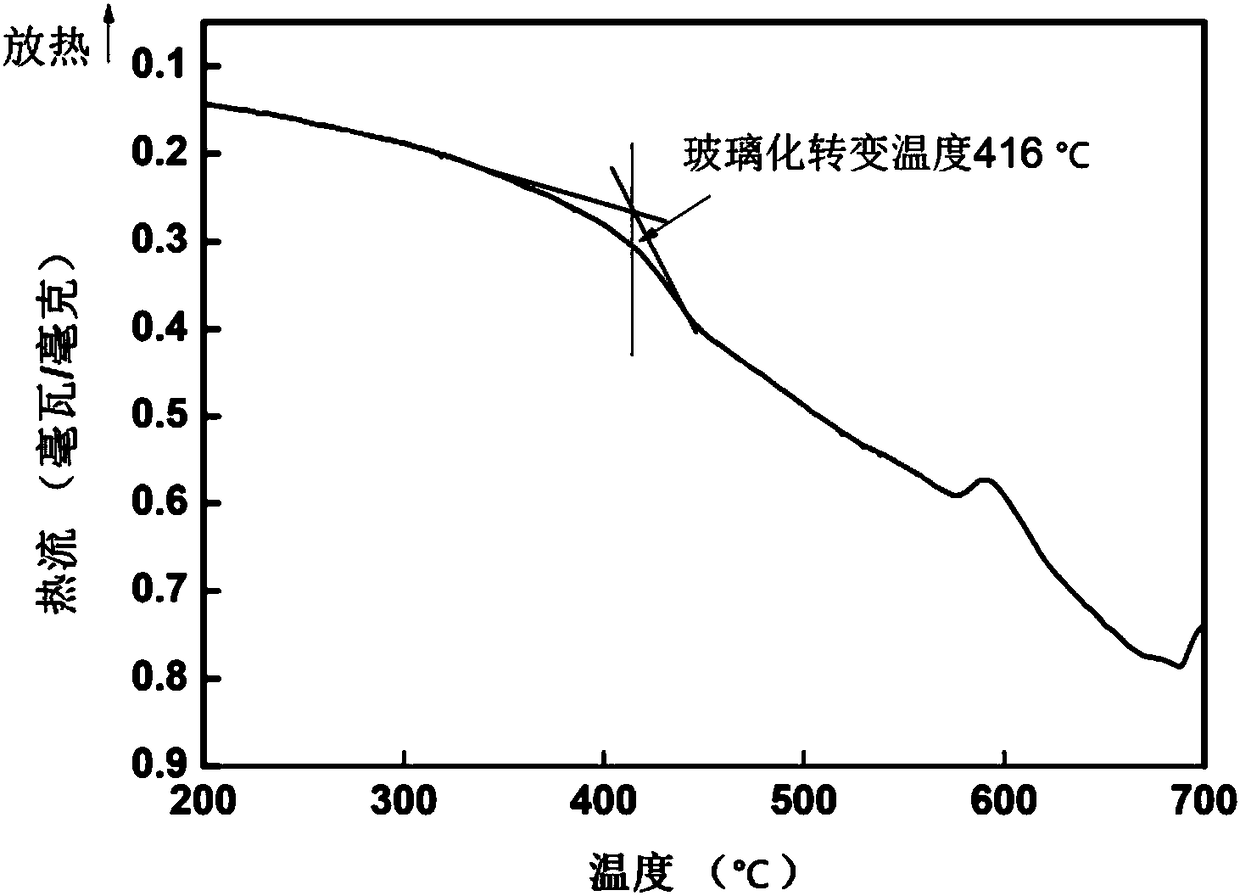

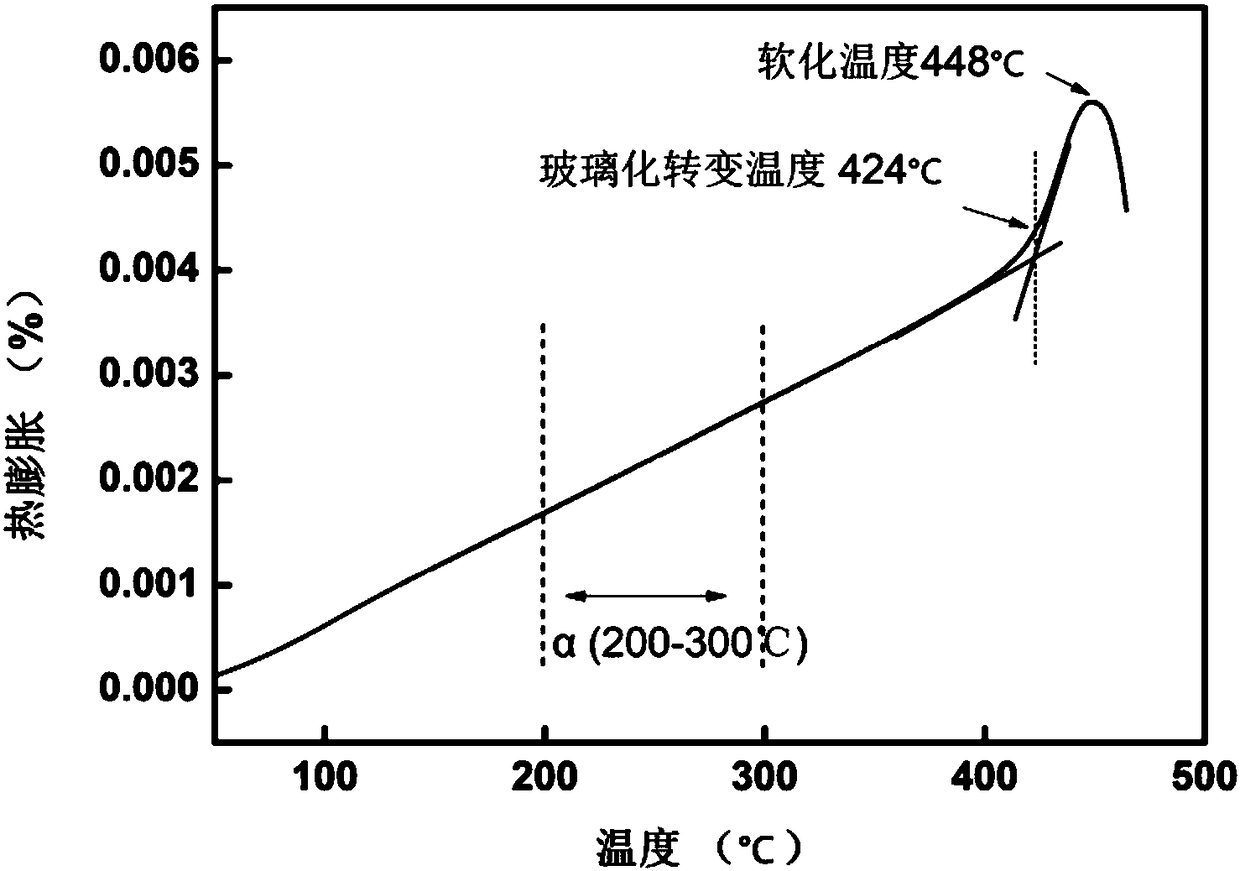

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com