Visible light responding photocatalyst and low temperature combustion synthesis method

A photocatalyst and visible light technology, applied in the field of photocatalysis, achieves the effects of easy phase formation, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

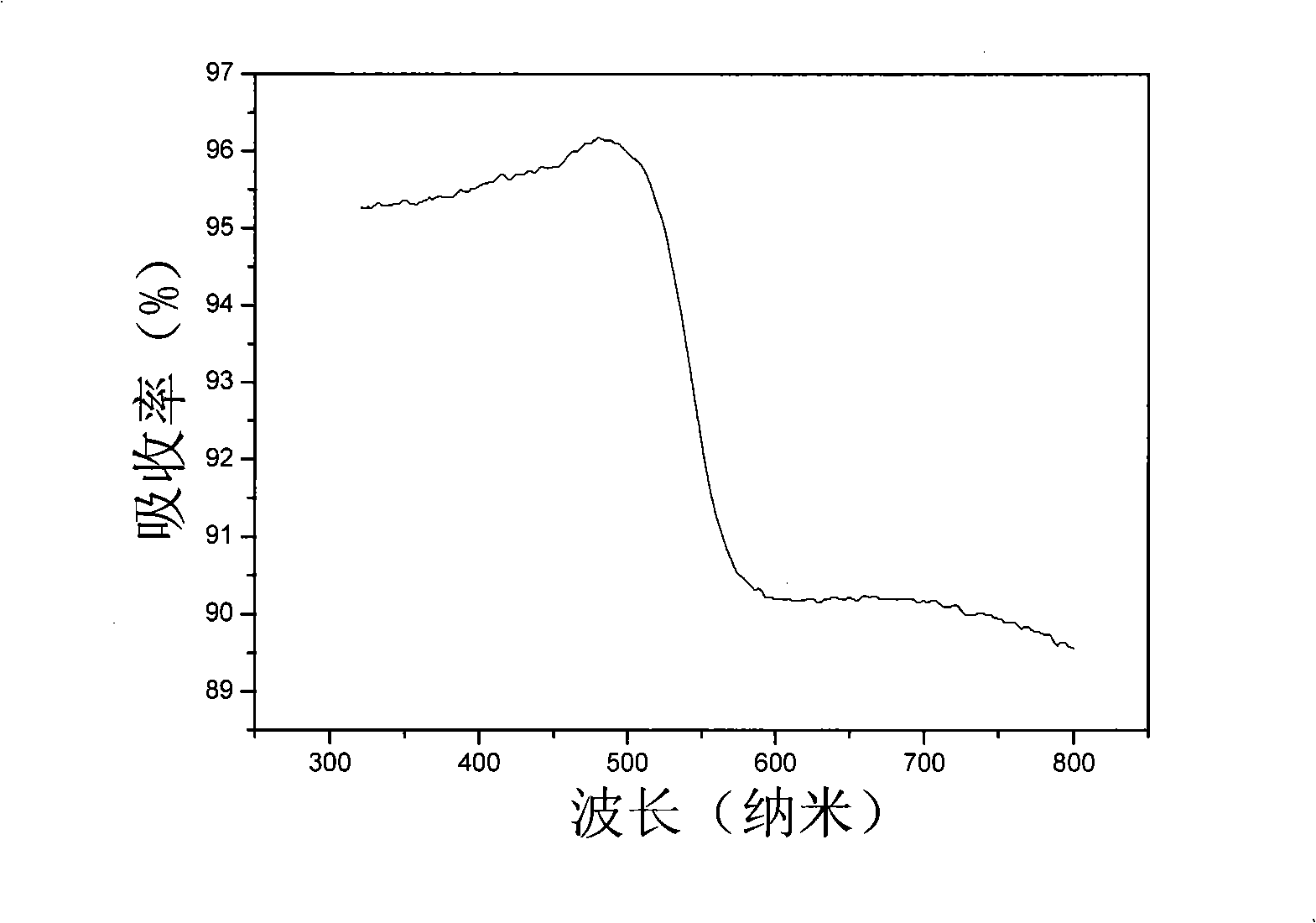

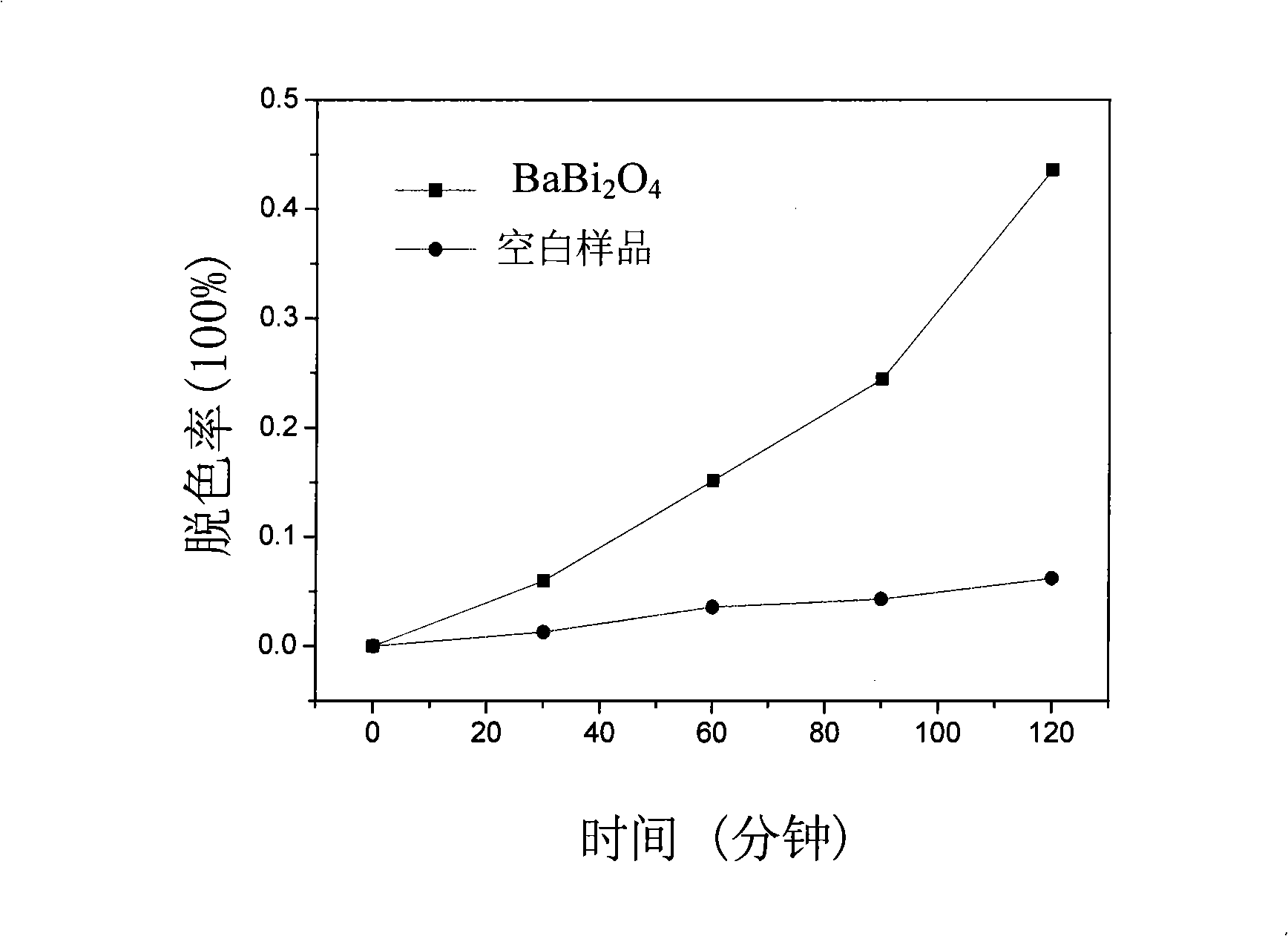

[0024] Barium bismuthate uses analytically pure Bi(NO 3 ) 3 ·5H 2 O and analytically pure Ba(NO 3 ) 2 Synthesized as raw material, according to BaO·Bi 2 o 3 stoichiometric ratio, weigh 0.97g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 12ml of 0.25mol / L ethylenediaminetetraacetic acid amine solution (7.3063g of ethylenediaminetetraacetic acid was dissolved in 20ml of concentrated ammonia water and deionized water was added to make up to 100ml) and 12ml of 0.5mol / L lemon In the mixed solution of acid solution (10.5g of citric acid monohydrate dissolved in 100ml of deionized water), due to the complexation of organic matter, it is easily hydrolyzed into Bi(NO 3 ) 3 ·5H 2 O completely dissolves to form a clear solution. Then add 0.261g Ba(NO 3 ) 2 , to obtain a transparent precursor solution after stirring and dissolving. Dehydrate the precursor solution at 160°C for 24 hours to obtain a black fluffy dry precursor, grind it, then heat the resulting precursor powder at a rat...

Embodiment 2

[0028] According to 2BaO·Bi 2 o 3 The stoichiometric batching, using analytically pure Bi(NO 3 ) 3 ·5H 2 O and analytically pure Ba(NO 3 ) 2 As a synthetic raw material, according to 2BaO·Bi 2 o 3stoichiometric ingredients, weigh 0.97gBi(NO 3 ) 3 ·5H 2 O is dissolved in the mixed solution of the amine solution of 16ml 0.25mol / L ethylenediaminetetraacetic acid and the glycine solution of 16ml 0.5mol / L, obtains containing Bi(NO 3 ) 3 ·5H 2 A clear solution of O. Then add 0.522g Ba(NO 3 ) 2 , to obtain a transparent precursor solution after stirring and dissolving. The precursor solution was dehydrated at 150°C for 10 hours to obtain a black fluffy dry precursor, which was ground and then heated to 400°C for 6 hours at a rate of 2°C / min. ℃ for 10 hours, you can get barium bismuth acid powder, but the degradation effect is better than BaO Bi 2 o 3 slightly worse.

Embodiment 3

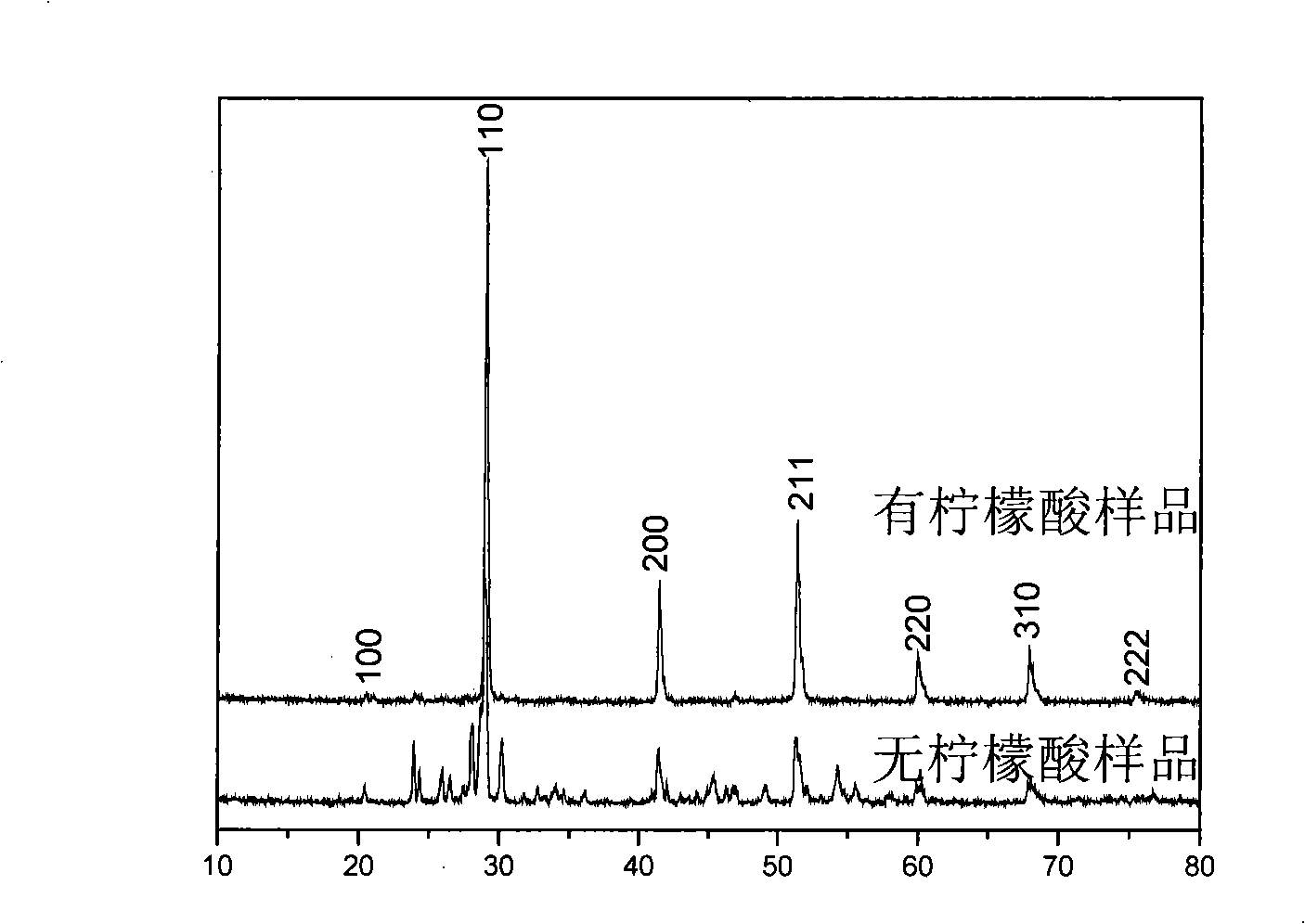

[0030] According to BaO·Bi 2 o 3 stoichiometric ratio, weigh 0.97g Bi(NO 3 ) 3 ·5H 2 O (analytically pure) is dissolved in 12ml of 0.25mol / L ethylenediaminetetraacetic acid amine solution, Bi(NO 3 ) 3 ·5H 2 O completely dissolves to form a clear solution. Then add 0.261g Ba(NO 3 ) 2 (Analytical pure), stirring and dissolving to obtain a transparent precursor solution. Dehydrate the precursor solution at 160°C for 24 hours to obtain a black fluffy dry precursor, grind it, then heat the resulting precursor powder at a rate of 2°C / min to 350°C for 10 hours, grind it, and finally put the powder at 600°C After 2 hours of heat preservation, a comparison sample without fuel citric acid can be obtained. After the reaction, the obtained product was filtered, washed three times with deionized water, then washed three times with absolute ethanol, and then dried at 75°C. through figure 1 The XRD component analysis shown in, the product is mainly Bi 2 o 3 and barium bismuthat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com