Optical glass melting method and optical glass melting device used for method

A technology of optical glass and melting furnace, which is applied in glass furnace equipment, glass manufacturing equipment, furnace, etc., can solve the problems of increased production cost and not completely eradicated, and achieve the effect of improving service life and high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

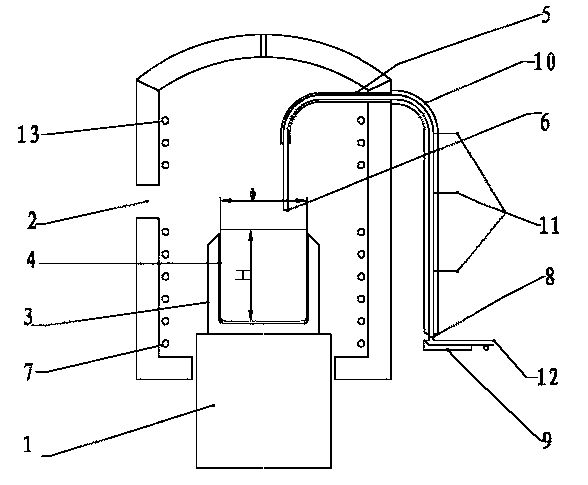

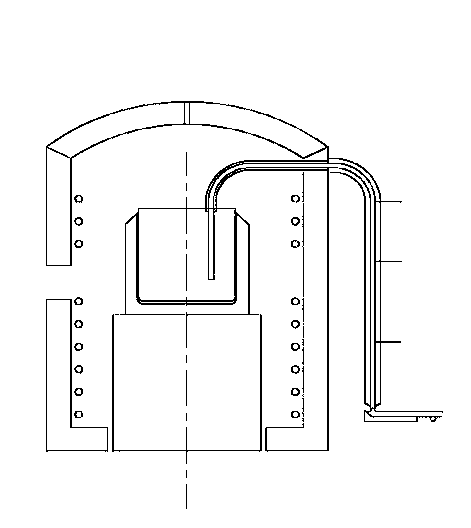

[0026] The optical glass melting method of the present invention and the optical glass melting device dedicated to the method will be described in detail below in turn.

[0027] 1. Furnace design

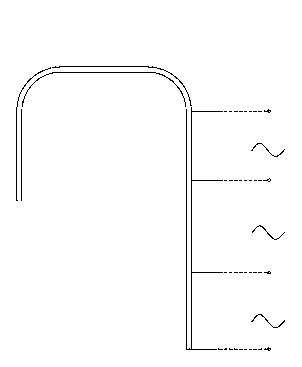

[0028] The melting furnace includes a furnace body, a heating body and a crucible 4, and a charging port 2 is arranged on the furnace body. The heating body includes a melting heating body 7 and a heat preservation heating body 13, the melting heating body 7 is located at the lower part of the furnace body, and the heat preservation heating body 13 is located at the upper part of the furnace body. The heating bodies 7 and 13 are arranged in two groups of upper and lower groups, and the furnace temperature is controlled in groups. Usually the lower temperature is higher than the upper temperature. The bottom of the furnace body is a liftable furnace bottom 1, and the insulation layer at the bottom of the crucible must have sufficient thickness. When lifting the crucible, ensure tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com