Ultra-wideband random laser scattering material based on amorphous bismuthate, laser device and preparation and application

A technology of scattering materials and random lasers, which is applied in the direction of laser scattering effects, laser components, lasers, etc., can solve the problems of difficult to achieve ultra-broadband and high cost, and achieve the effect of flexible form and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

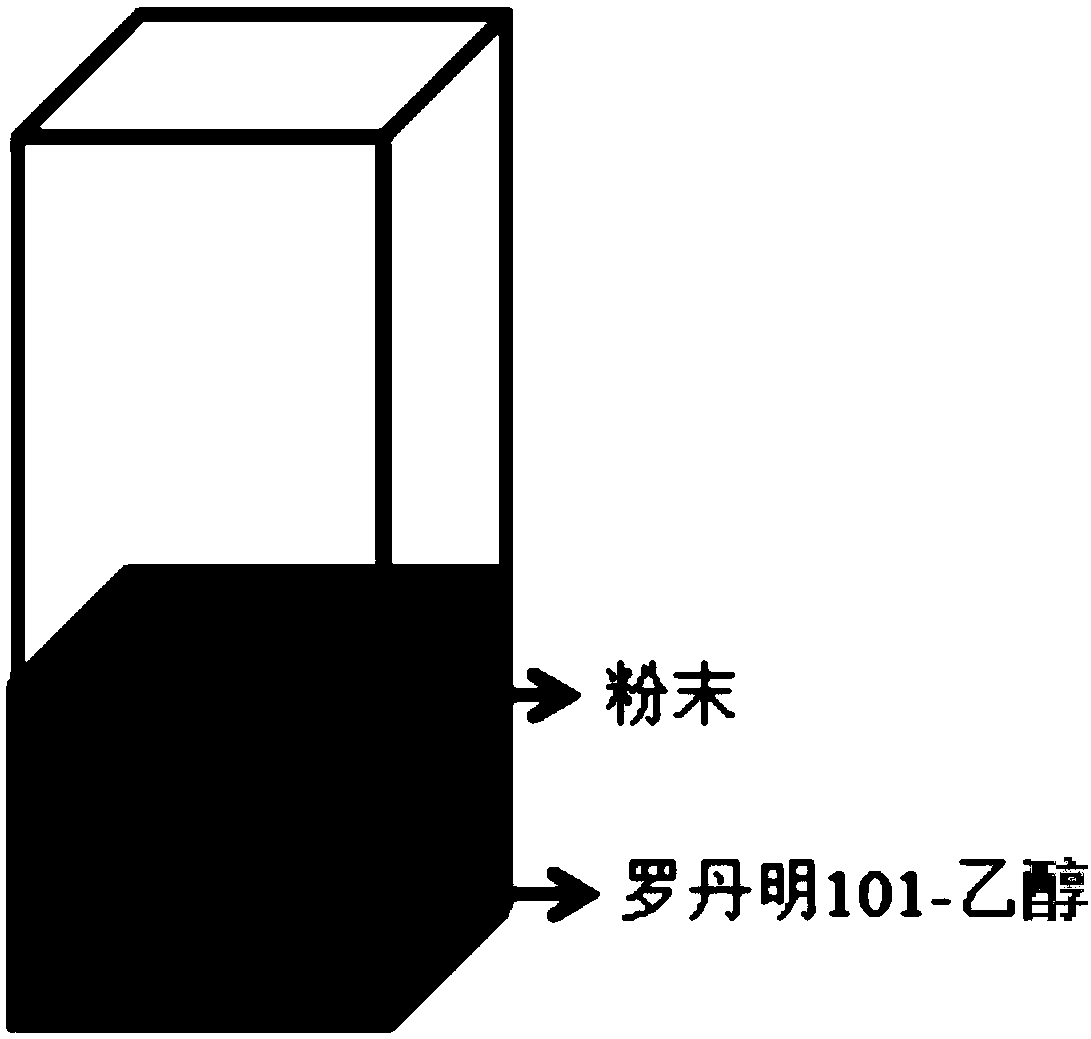

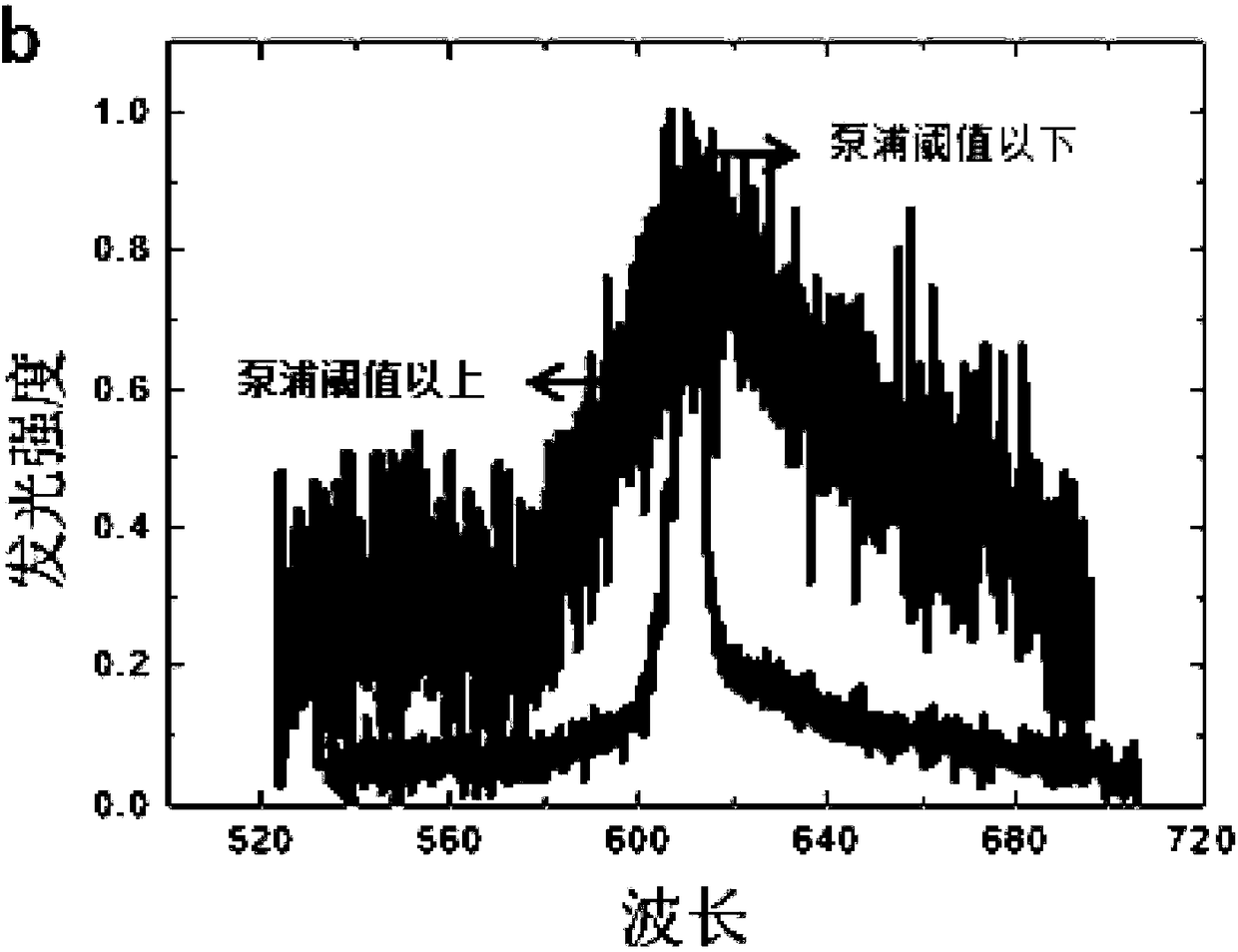

[0041] The chemical composition of the amorphous bismuth salt material of the present embodiment is Bi 2 o 3 : 65mol%; B2 o 3 : 20mol%; Ga 2 o 3 : 15mol%. Glass raw material selection of analytical pure Bi 2 o 3 , B 2 o 3 , Ga 2 o 3 . According to the mole percentage, after grinding and mixing evenly, put it in an alumina crucible, melt it at a certain temperature, pour the melt on a stainless steel plate, press it, anneal it at the glass transition temperature for 2 hours, and then ball mill the block material. The ball-milled powder was used as a strong scatterer, and the powder was dispersed in water to form a 15 mg / mL suspension. Take more than 1mL of the suspension, add 0.1mL of 10mM rhodamine 101-ethanol solution, and disperse by ultrasonic for 1 minute to obtain a suspension, and put the suspension into a transparent cuvette to obtain an ultra-broad band based on amorphous bismuthate. random laser device. Structural diagram such as figure 1 shown.

[0042...

Embodiment 2

[0044] The chemical composition of the amorphous bismuth salt material of the present embodiment is Bi 2 o 3 : 65mol%; B 2 o 3 : 20mol%; Ga 2 o 3 : 15mol%. Glass raw material selection of analytical pure Bi 2 o 3 , B 2 o 3 , Ga 2 o 3 . According to the molar percentage, after grinding and mixing evenly, put it in an alumina crucible, melt it at a certain temperature, pour the glass melt on a stainless steel plate, press it, anneal it for 2 hours near the glass transition temperature, and then ball mill the block material , the ball-milled powder is used as a strong scatterer, and the powder is compressed into thin flakes by a tablet press (pressure is 10 MPa). Mix 10 mL of 0.12 g / mL polyvinyl alcohol-water solution with 1 mL of 10 mM rhodamine 6G-ethanol solution. Use a pipette gun to draw 30 μl of the mixed solution and drop it on the sheet, make it penetrate into the gap of the solid sheet, and dry it in an oven for half an hour to obtain an ultra-broadband rand...

Embodiment 3

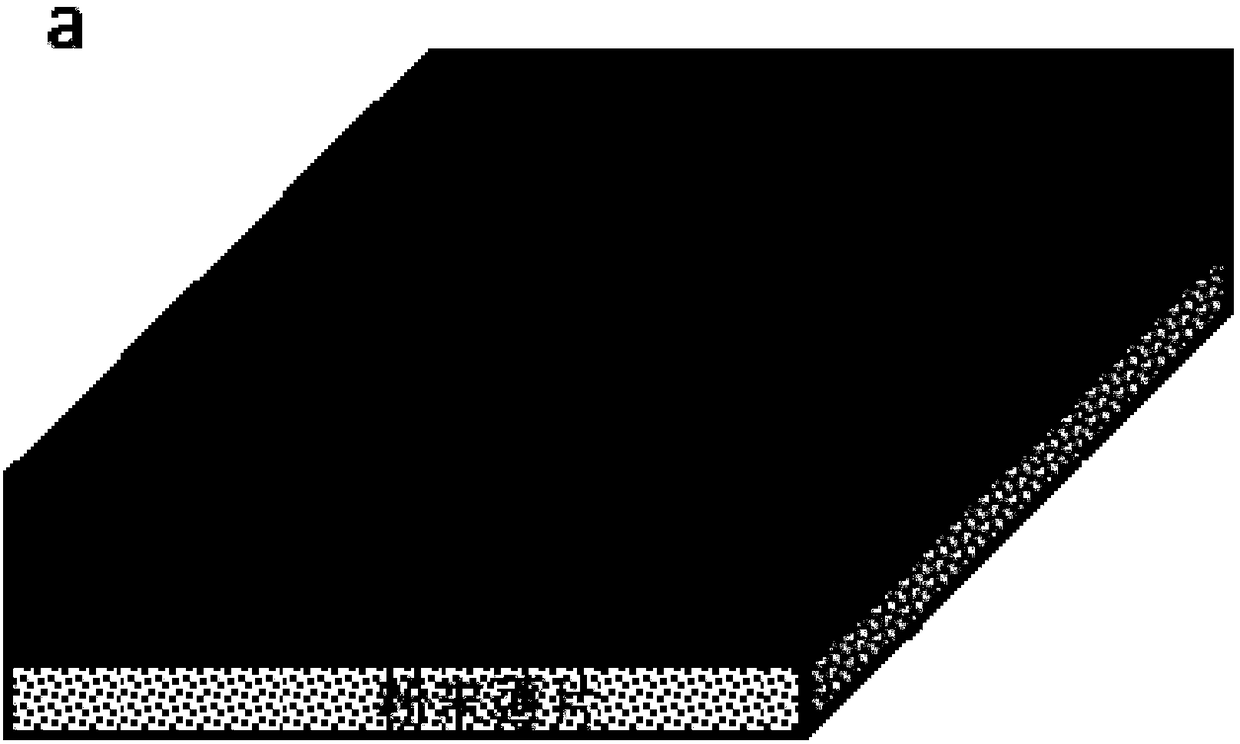

[0047] The chemical composition of the amorphous bismuth salt material of the present embodiment is Bi 2 o 3 : 65mol%; B 2 o 3 : 20mol%; Ga 2 o 3 : 15mol%. Glass raw material selection of analytical pure Bi 2 o 3 , B 2 o 3 , Ga 2 o 3 . After mixing according to the mole percentage, put it in an alumina crucible, melt it at a certain temperature, pour the glass melt on a stainless steel plate, press it, anneal it for 2 hours near the glass transition temperature, and then ball mill the block material. The powder acts as a strong scatterer. The powder was dispersed in water to form a 15mg / mL suspension, and 0.2mL was spin-coated on a glass substrate (spin-coating speed: 6000rpm, spin-coating time: 30s). Mix 1mL of 0.3g / mL polyvinyl alcohol aqueous solution and 0.25mL of 10mM ethanol solution of Rhodamine 800 evenly, get 0.2mL and drop evenly on the above sample, and spin-coat to obtain a polyvinyl alcohol film containing Rhodamine 800 (spin coating Speed: 6000rpm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com