High-temperature-resistant composite modified asphalt for roads and preparation method thereof

A composite modified asphalt, high temperature resistant technology, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems of poor binding force of asphalt mixture and insignificant overall performance improvement effect of asphalt pavement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

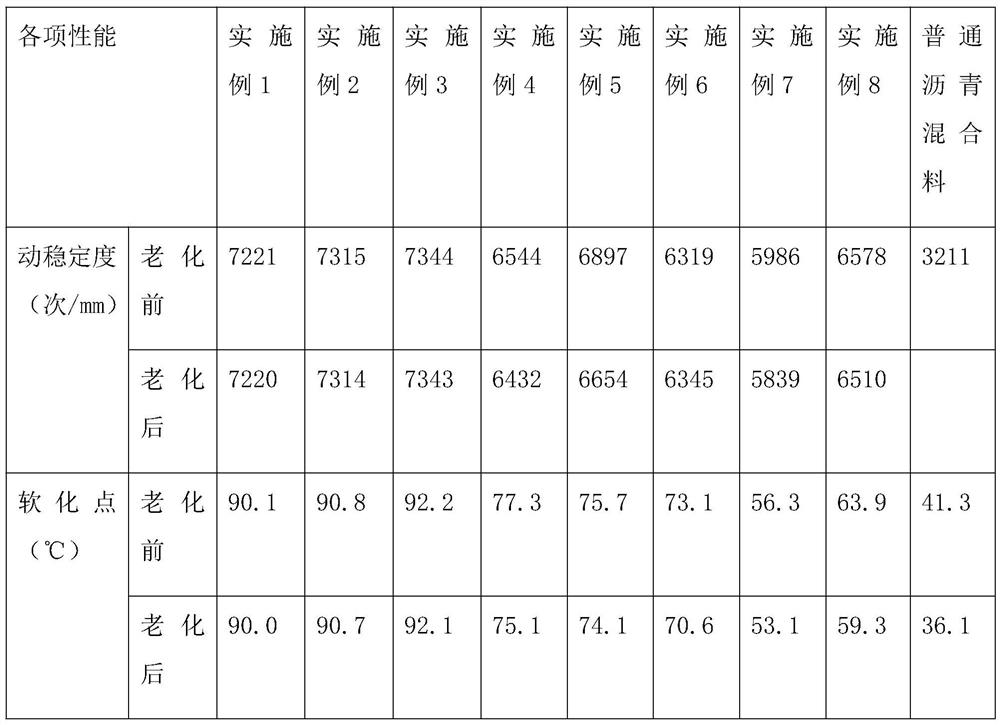

Examples

Embodiment 1

[0050] A high-temperature-resistant composite modified asphalt for roads. The raw material components are as follows: in parts by weight, 30 parts of n-hexylamine, 30 parts of functional polymers, 20 parts of activated waste glass powder, 50 parts of styrene, divinylbenzene 40 parts, 100 parts of epoxy pitch, 10 parts of dithiothreitol, 25 parts of zinc nitrate hexahydrate, 20 parts of potassium persulfate, 40 parts of sodium citrate, 80 parts of epoxy resin, 30 parts of aminoalkyl silane coupling agent , 30 parts of epoxy silane coupling agent, 80 parts of chain extender, 100 parts of carboxy silicone oil, 90 parts of mineral fiber, 30 parts of antioxidant, 60 parts of aggregate.

[0051] The functional polymer includes the following raw material components: in parts by weight, 10 parts of iodine, 20 parts of azobisisobutyronitrile, 50 parts of butadiene, 10 parts of 4-vinylbenzyl chloride, and 10 parts of initiator , 10 parts of potassium thioacetate, 18 parts of octadecyldi...

Embodiment 2

[0067] A high-temperature-resistant composite modified asphalt for roads. The raw material components are as follows: in parts by weight, 35 parts of n-hexylamine, 40 parts of functional polymers, 30 parts of activated waste glass powder, 55 parts of styrene, divinylbenzene 45 parts, 150 parts of epoxy pitch, 13 parts of dithiothreitol, 30 parts of zinc nitrate hexahydrate, 25 parts of potassium persulfate, 50 parts of sodium citrate, 85 parts of epoxy resin, 35 parts of aminoalkyl silane coupling agent , 35 parts of epoxy silane coupling agent, 90 parts of chain extender, 110 parts of carboxy silicone oil, 100 parts of mineral fiber, 35 parts of antioxidant, 70 parts of aggregate.

[0068] The functional polymer includes the following raw material components: in parts by weight, 15 parts of iodine, 25 parts of azobisisobutyronitrile, 60 parts of butadiene, 20 parts of 4-vinylbenzyl chloride, and 12 parts of initiator , 14 parts of potassium thioacetate, 19 parts of octadecyld...

Embodiment 3

[0084] A high-temperature-resistant composite modified asphalt for roads. The raw material components are as follows: in parts by weight, 40 parts of n-hexylamine, 50 parts of functional polymers, 50 parts of activated waste glass powder, 60 parts of styrene, divinylbenzene 50 parts, 200 parts of epoxy pitch, 16 parts of dithiothreitol, 35 parts of zinc nitrate hexahydrate, 30 parts of potassium persulfate, 60 parts of sodium citrate, 90 parts of epoxy resin, 40 parts of aminoalkyl silane coupling agent , 40 parts of epoxy silane coupling agent, 100 parts of chain extender, 120 parts of carboxy silicone oil, 110 parts of mineral fiber, 40 parts of antioxidant, 80 parts of aggregate.

[0085] The functional polymer includes the following raw material components: in parts by weight, 20 parts of iodine, 30 parts of azobisisobutyronitrile, 80 parts of butadiene, 30 parts of 4-vinylbenzyl chloride, and 14 parts of initiator , 16 parts of potassium thioacetate, 20 parts of octadecyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com