Preparation method of polyaniline compounded zinc bismuthate nano-rods

A technology for compounding zinc bismuthate and polyaniline, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of complex preparation process and difficulty in preparation of uniform properties, and achieve simple preparation process, good application prospects, easy The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

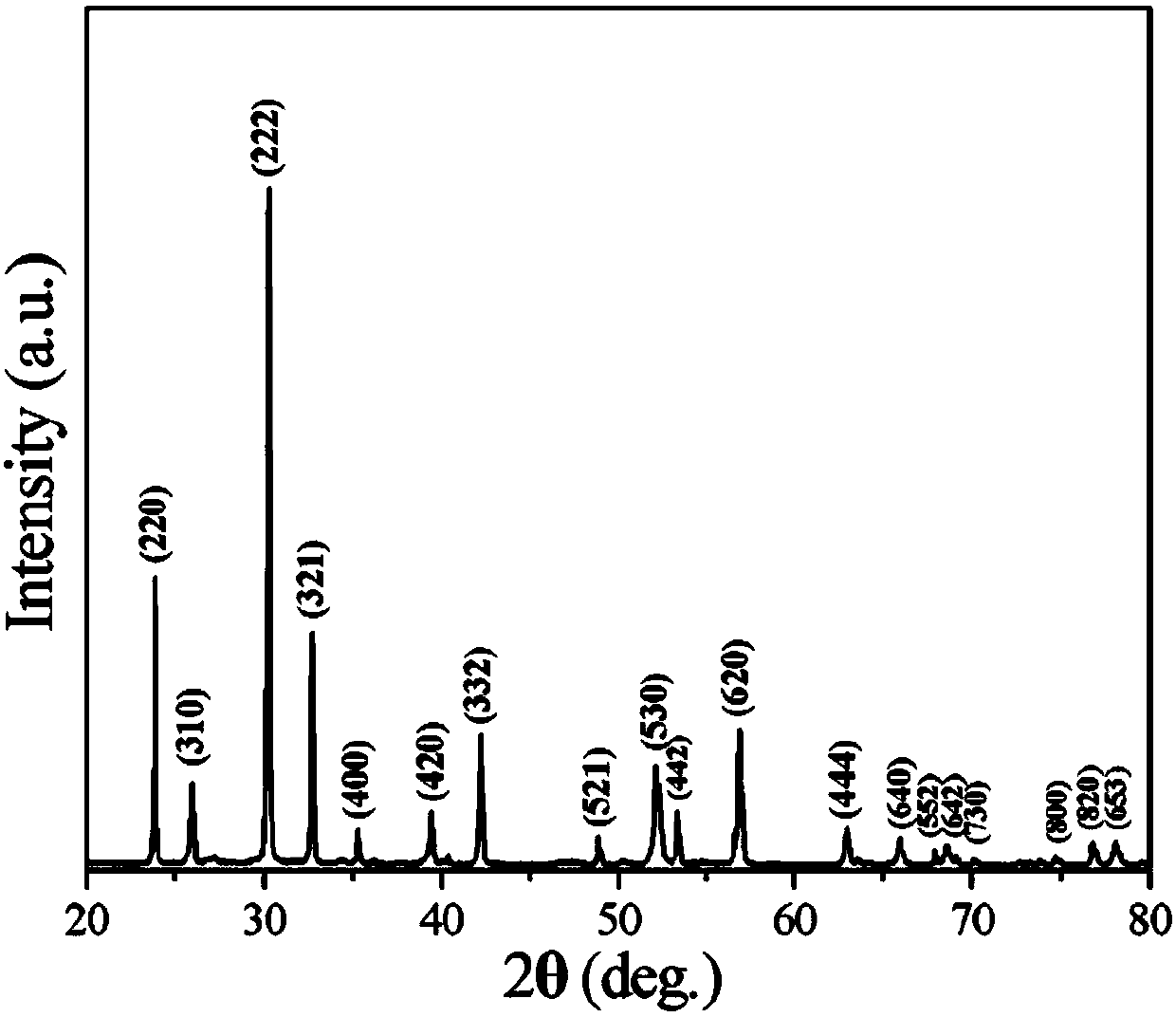

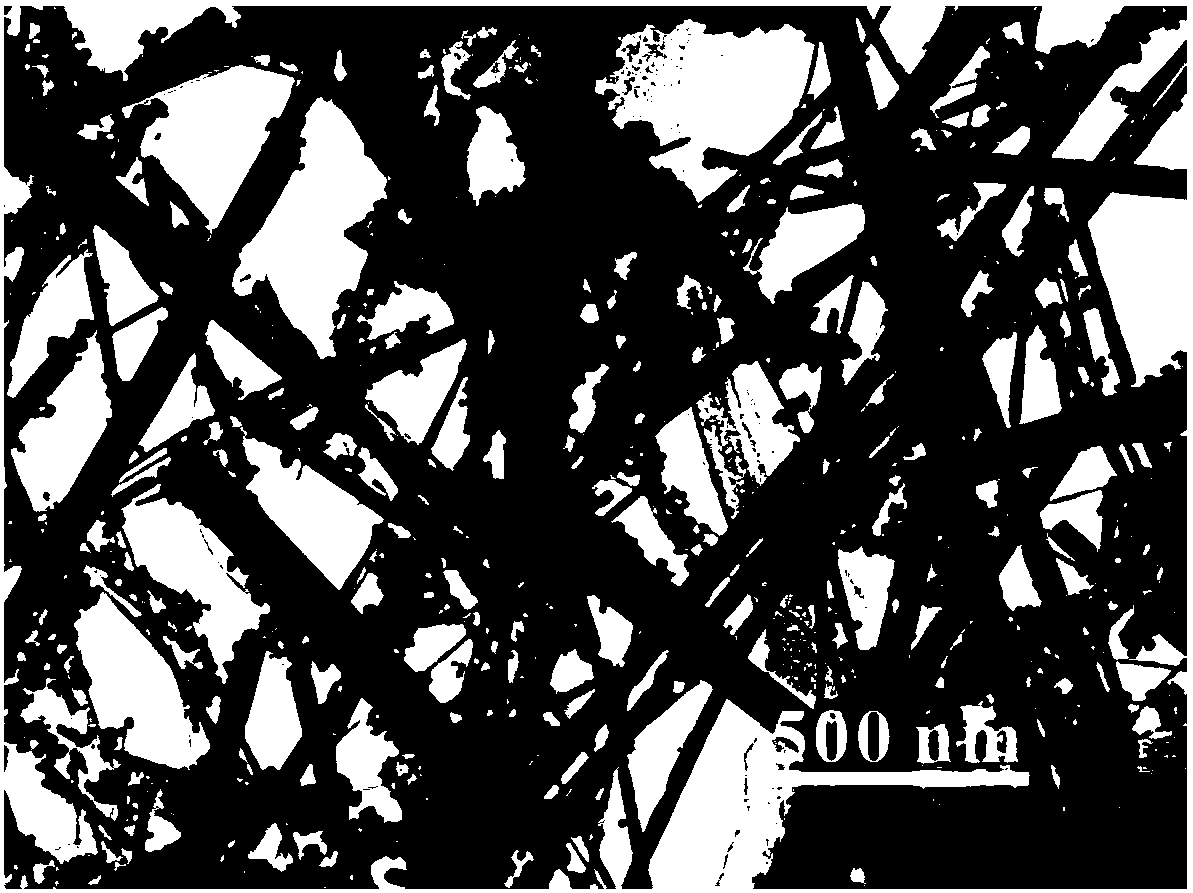

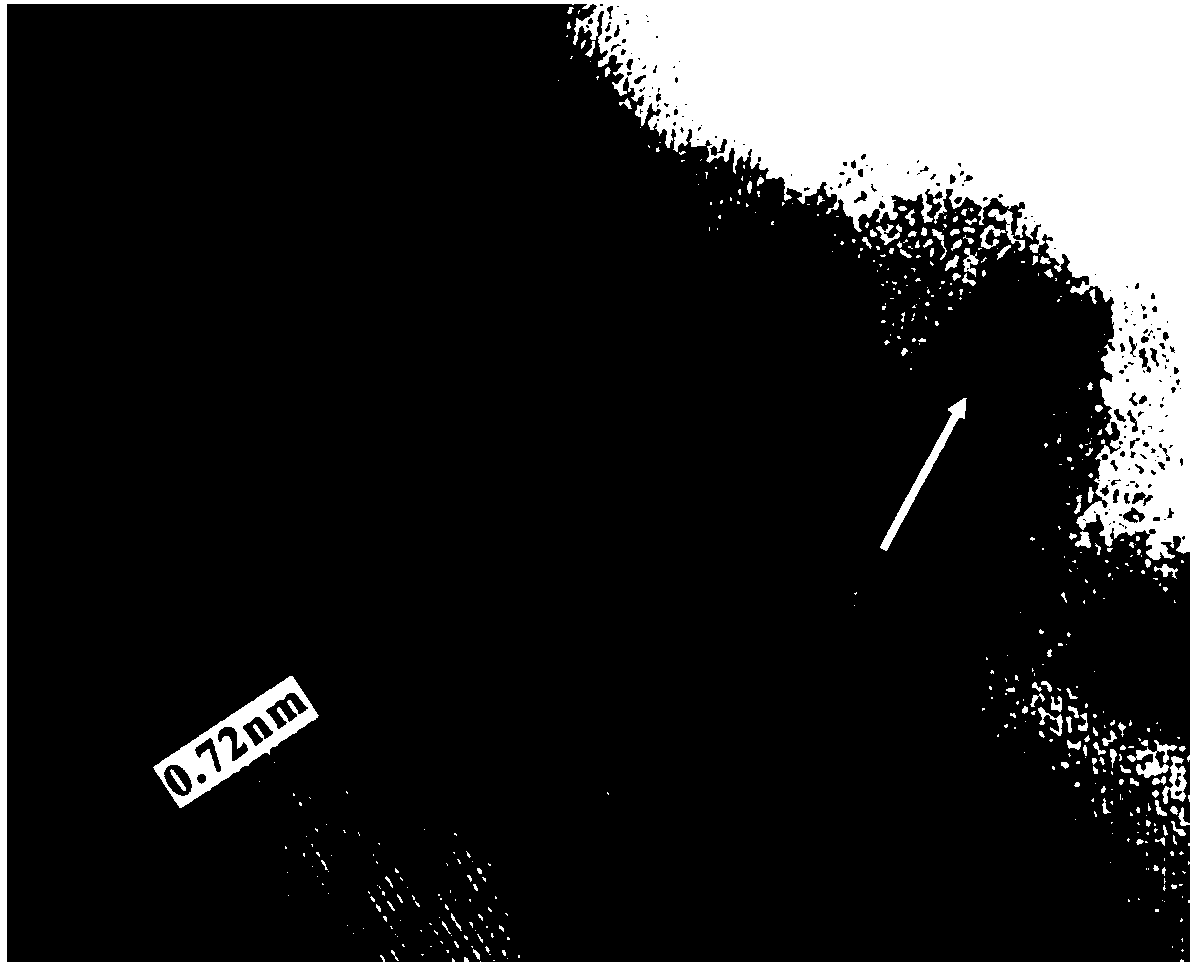

[0022] First mix sodium bismuthate and zinc acetate evenly, wherein the molar ratio of sodium bismuthate to zinc acetate is 38:1, then place the mixed powder of sodium bismuthate and zinc acetate in the high temperature zone of the corundum tube reaction vessel, and place the polyaniline In the low-temperature zone of the corundum tube reaction vessel, the weight of polyaniline accounts for 30% of the weight of sodium bismuthate and zinc acetate, and the corundum tube is sealed, and the high-temperature zone is heated to a temperature of 1400°C, and the low-temperature zone is heated to 300°C. The air velocity is 200cm 3 / min, thus obtaining polyaniline-composite zinc bismuthate nanorods with a diameter of 20-100 nm and a length of 1-2 μm on the surface of the water-cooled end of the corundum tube, with random polyaniline particles attached to the surface.

Embodiment 2

[0024] First mix sodium bismuthate and zinc acetate evenly, wherein the molar ratio of sodium bismuthate to zinc acetate is 38:1, then place the mixed powder of sodium bismuthate and zinc acetate in the high temperature zone of the corundum tube reaction vessel, and place the polyaniline In the low-temperature zone of the corundum tube reaction vessel, the weight of polyaniline accounts for 15% of the weight of sodium bismuthate and zinc acetate, and the corundum tube is sealed, and the high-temperature zone is heated to a temperature of 1200°C, and the low-temperature zone is heated to 200°C. The air velocity is 100cm 3 / min, thus obtaining polyaniline-composite zinc bismuthate nanorods with a diameter of 20-100 nm and a length of 1-2 μm on the surface of the water-cooled end of the corundum tube, with random polyaniline particles attached to the surface.

Embodiment 3

[0026] First mix sodium bismuthate and zinc acetate evenly, wherein the molar ratio of sodium bismuthate to zinc acetate is 38:1, then place the mixed powder of sodium bismuthate and zinc acetate in the high temperature zone of the corundum tube reaction vessel, and place the polyaniline In the low-temperature zone of the corundum tube reaction vessel, the weight of polyaniline accounts for 16% of the weight of sodium bismuthate and zinc acetate, and the corundum tube is sealed, and the high-temperature zone is heated to a temperature of 1220°C, and the low-temperature zone is heated to 210°C. The air velocity is 120cm 3 / min, thus obtaining polyaniline-composite zinc bismuthate nanorods with a diameter of 20-100 nm and a length of 1-2 μm on the surface of the water-cooled end of the corundum tube, with random polyaniline particles attached to the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com